6A. 20 1973 OPEL SERVICE MANUAL

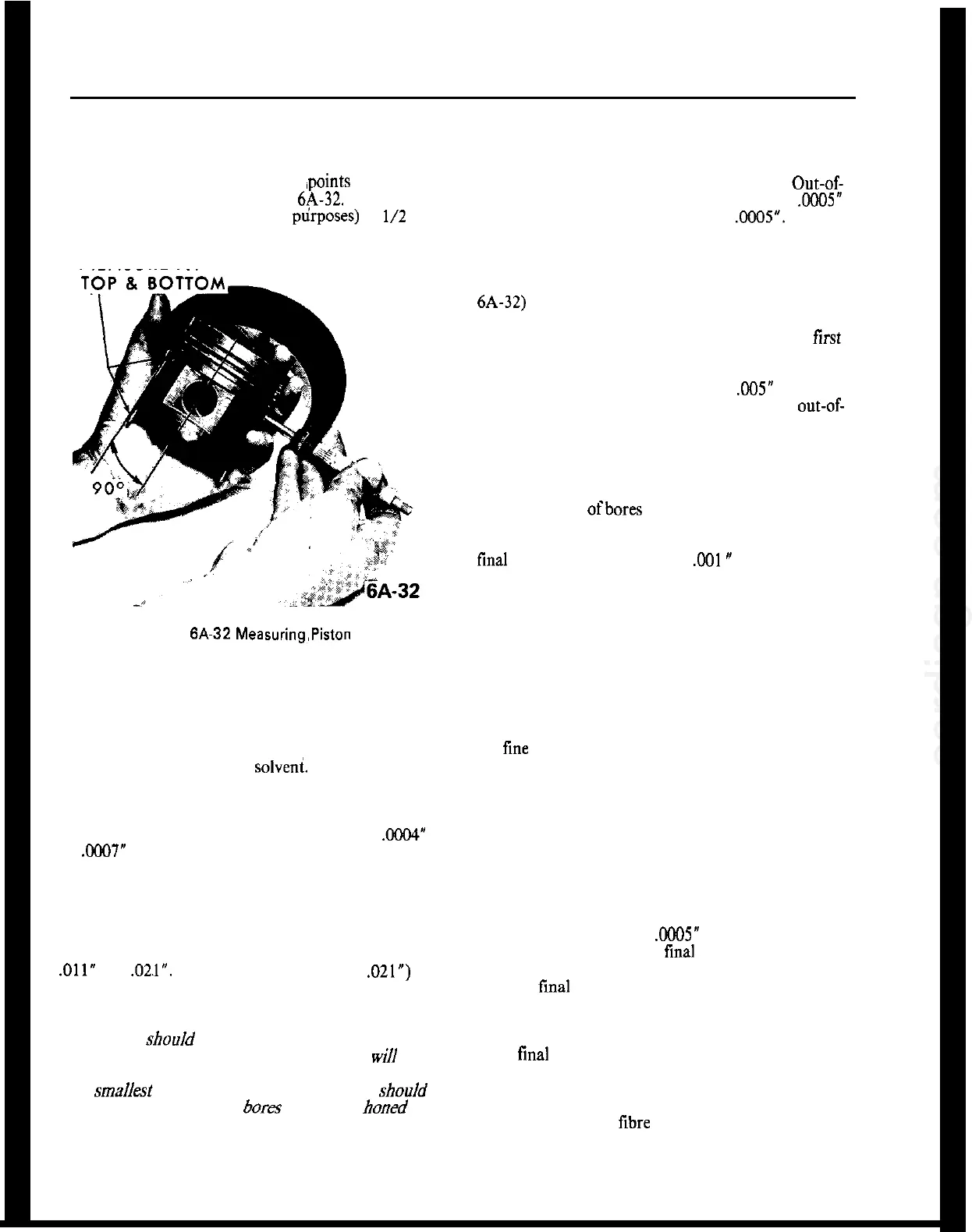

diameter at the right angle to the piston pin is greater

than the diameter parallel to the piston pin. When a

piston is checked for size, it must be measured with

micrometers applied to the skirt at

,points

90 degrees

to the piston pin. See Figure

6A-32.

The piston

should be measured (for fitting p&poses) 2

l/2

in-

ches below the top of piston.

MEASURE AT

Figure 6A-32

Measuring,Piston

Inspect bearing surfaces of piston pins. Check for

wear by measuring worn and unworn surfaces with

micrometers. Rough or worn pins should be re-

placed. Check fit of piston pins in piston bosses.

Occasionally pins will be found tight due to gum or

varnish deposits. This may be corrected by removing

the deposit with a suitable solveni. If piston bosses

are worn out-of-round or oversize, the piston and pin

assembly must be replaced. Oversize pins are not

practical because the pin is a press fit in the connect-

ing rod. Piston pins must tit the piston with

0X4”

to

.OCHl7”

clearance.

Examine all piston rings for scores, chips or cracks.

Check compression rings for tension by comparing

with new rings. Check gap of compression rings by

placing rings in bore at bottom of ring travel. Meas-

ure gap with feeler gage. Gap should be between

,011”

and

.02.1”.

If gaps are excessive (over .021”) it

indicates the rings have worn considerably and

should be replaced.

No attempt should be made to cut down oversize

pistons to fit cylinder bores. This practice

will

de-

stroy the surface treatment and affect the weight.

The

sma/Jest

possible oversize service pistons shouId

be used and the cylinder bores should be honed to

size for proper clearance.

1. Before installing piston, piston rings, or reboring

cylinders, observe the following:

Cylinder bores may not be the same size. Standard

replacement piston sizes are in the midpoint of the

cylinder bore size range. Therefore, it may be neces-

sary to hone cylinders for correct piston tit. Out-of-

round on cylinder bore must not exceed

.ooO5”

maximum with a taper of not over

.OilO5”.

Before the honing or reboring operation is started,

measure all new pistons with micrometer contacting

at points exactly 90 degrees to piston pin (Figure

6A-32) then select the smallest piston for the first

fitting. The slight variation usually found between

pistons in a set may provide for correction if the first

piston has excessive clearance.

If wear of cylinder does not exceed

.005”

honing is

recommended for truing the bore. If wear or

out-of-

round exceeds these limits, the bore should be trued

up with a fly cutter boring bar and then finish honed.

When reboring cylinders, all crankshaft bearing caps

must be in place and tightened to proper torque to

avoid distortion ofbores in final assembly. Always be

certain the crankshaft is out of the way of the boring

cutter when boring each cylinder. When making the

final cut with boring bar, leave

,001

w

on the diameter

for finish honing to give the required clearance speci-

fied.

When honing cylinders, use clean sharp stones of

proper grade for the required amount of metal to be

removed, in accordance with instructions of the hone

manufacturer. Dull or dirty stones cut unevenly and

generate excessive heat. When using coarse or

medium grade stones use care to leave sufficient

metal so that all stone marks may be removed with

the fine stones used for finishing in order to maintain

proper clearance.

When finish honing, pass the hone through the entire

length of cylinder at the rate of approximately 60

cycles per minute. This should produce the desired

45 degree cross hatch pattern on cylinder walls

which will insure maximum ring life and minimum

oil consumption.

It is of the greatest importance that refinished cylin-

der bores have not over

.0005”

out-of-round or ta-

pered. Each bore must be final honed to remove all

stone or cutter marks and provide a smooth surface.

During final honing, each piston must be fitted in-

dividually to the bore in which it will be installed and

should be marked to insure correct installation.

After final honing and before the piston is checked

for fit, each cylinder bore must be thoroughly

washed to remove all traces of abrasive and then

dried. The dry bore should then be brushed clean

with a power-driven iibre brush. If all traces of abra-

sive are not removed, rapid wear of new pistons and

rings will result. Fit new pistons in the following

manner:

Loading...

Loading...