6A- 22 1973 OPEL SERVICE MANUAL

I.

NO.

I

COMPRESSION - GAP IN FRONT

2. NO. 2 COMPRESSION - GAP IN REAR

3. UPPER STEEL BAND -

I

-

2

IN.TOWARDS

THE LEFT OF INTERMEDIATE RING GAP

4. INTERMEDIATE RING - GAP IN FRONT

5. LOWER STEEL BAND -

I

- 2 IN.TOWARDS

THE RIGHT OF INTERMEDIATE RING GAP.

‘A” VERTICAL LINE FOR PISTON AND RINGS, FRONT

6A-36

Figure 6A-36 Location of Piston Ring Gaps

With rings installed on piston, check clearance in

grooves by inserting feeler gages between each ring

and its Iower land. Any wear that occurs forms a

step at inner portion of the lower land. If the piston

grooves have worn to the extent that relatively high

steps exist on the lower lands, the piston should be

replaced since steps will interfere with the operation

of new rings causing ring clearances to become exces-

sive. Piston rings are not furnished in oversize widths

to compensate for ring groove wear.

When fitting new rings to new pistons, the side clear-

ance of the compression rings should be X024”

-

.1X34”

(top) and

.0013”

-

.OO24”

(2nd), and the oil

ring clearance should be

.OO13”

-

.0024”.

Assembly of Piston and Connecting Rod

NOTE:

Connecting rods may be out of alignment

due to shipping or hand/i& Always check a new

rod before installing piston and pin.

Inspect piston pin bores and piston pins for wear.

Piston pin bores and piston pins must be free of

varnish or scuffing when being measured. The piston

pin should be measured with a niicrometer and the

piston pin bore should be measured with a dial bore

gage or an inside micrometer. If clearance is in excess

of the

,001”

wear limit, the piston and piston pin

assembly should be replaced.

1. Lubricate piston pin holes in piston and connect-

ing rod to facilitate installation of pin.

2. Install pin in following manner:

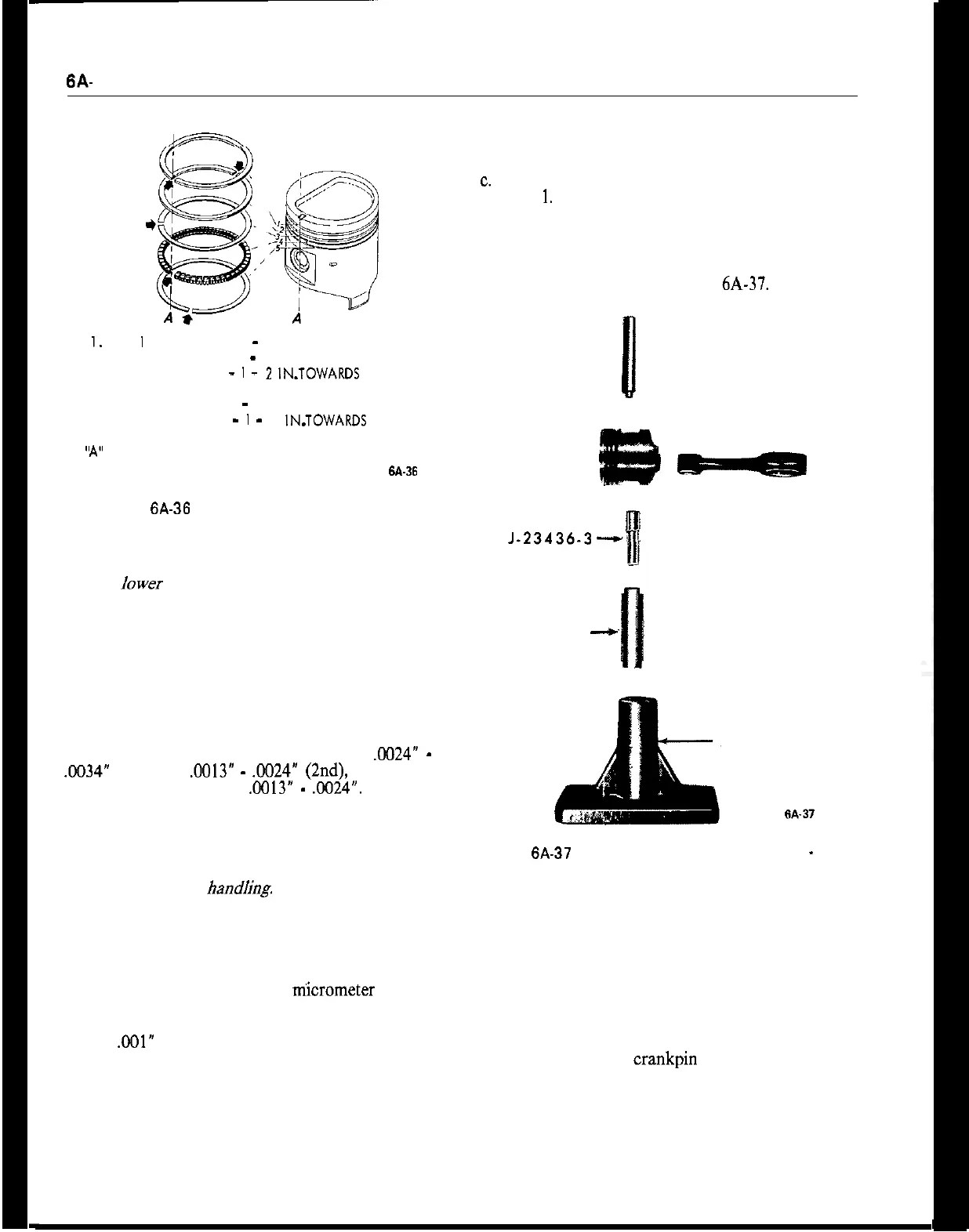

a. Position base support J-6047 on hydraulic press.

b. Place tool J-23436-l in support J-6047 with small

diameter bore facing upward.

c.

Place small end of tool J-23436-3 in bore of tool

J-23436-

1.

d. Position piston, rod, and pin guide J-23436-3.

e. Line up pin on piston, and using tool J-23436-4

press pin into piston. See Figure 6A-37.

Ii

-J-23436-4

J-23436-3--,

J-23436-1

--c

J-6047

Figure 6A-37 Piston Pin Installation Tool Layout

-

1.9

Engine

3. Remove installer from connecting rod and piston

assembly and check piston for freedom of movement

on piston pin.

4. Make sure cylinder bores, pistons, connecting rod

bearings and crankshaft journals are absolutely

clean, then coat all bearing surfaces with engine oil.

5. Before installation of a piston and rod assembly in

its bore, position the crankpin straight down.

6. Remove connecting rod cap.

7. Make sure the gap in the oil ring rails and the gaps

of the compression rings are positioned correctly.

8. Lubricate the piston and rings and install in bore

Loading...

Loading...