6A- 26 1973 OPEL SERVICE MANUAL

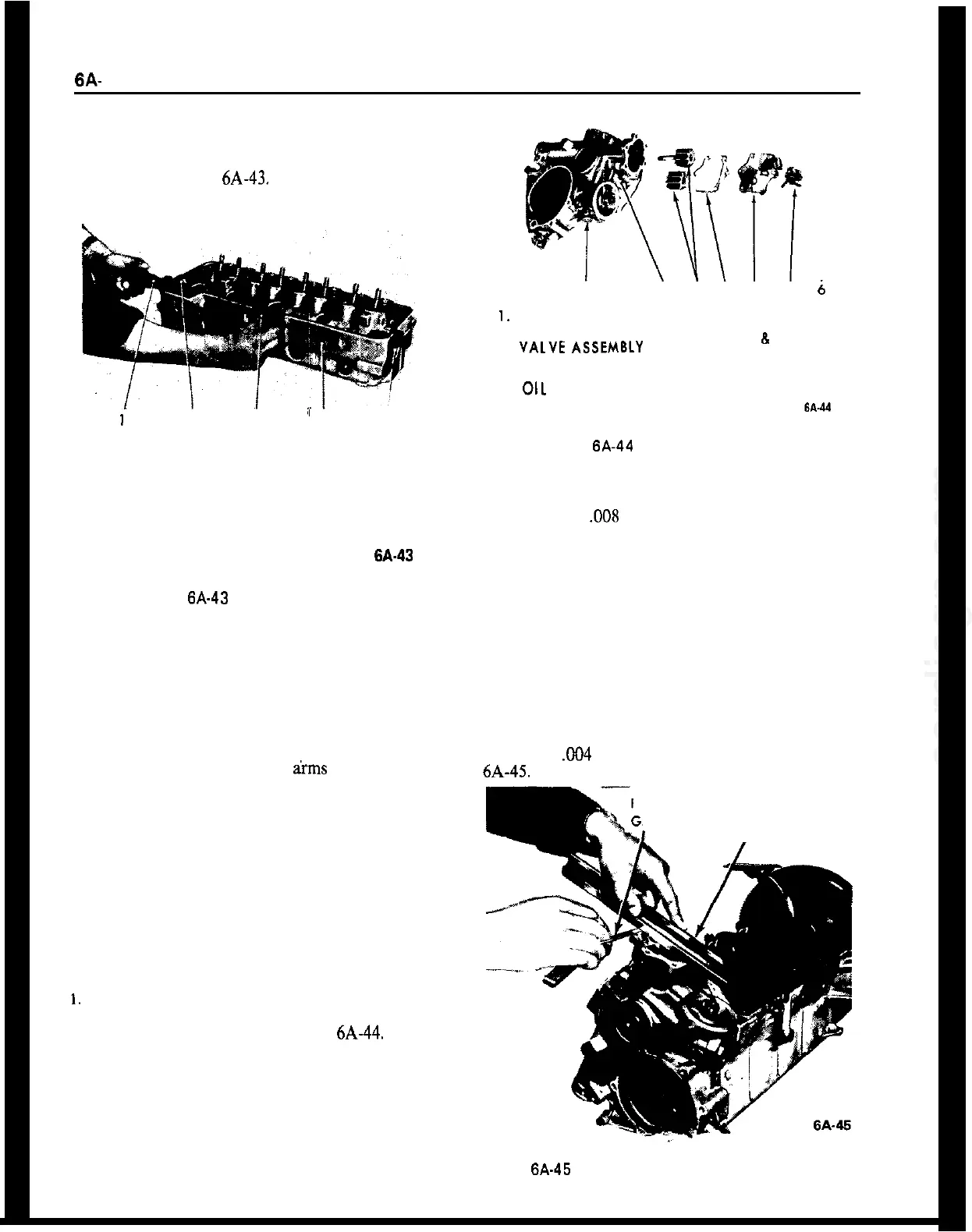

rear of cylinder head. Remove camshaft toward

front, supporting camshaft with one hand through

access hole and taking care not to damage bearing

surfaces. See Figure 6A-43.

1

2

345 6

I.

OLD PRESSURE

4. COVER GASKET

RELIEF

~~-

\SSEMBLY

5. COVER 8 VALVE

ASSEMBLY

VALVE

I

2. TIMING CASE

6. COVER ATTACHING

3. OIL PUMP GEARS

SCREWS

1

2 3

”

4

5

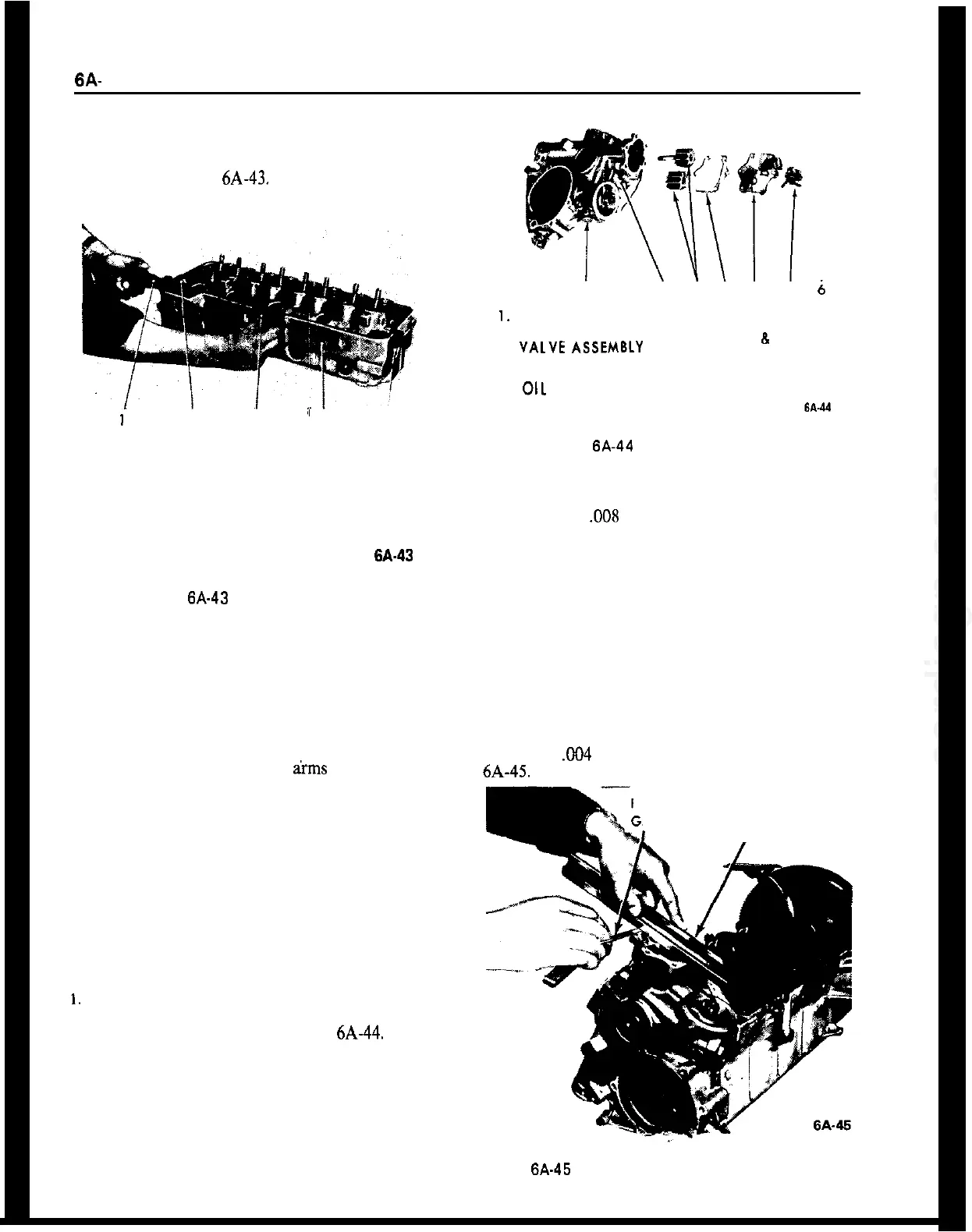

Figure 6A-44 Oil Pump Components

1.

CAMSHAFT

2. FRONT ACCESS HOLE

3. LATERAL ACCESS HOLE

4. CYLINDER HEAD

5. REAR ACCESS HOLE

ISA-43

Figure 6A-43 Removing Camshaft

Installation

1. Liberally lubricate camshaft journals and install

camshaft from front into cylinder head. Support

shaft through access hole in left side of head to pre-

vent damaging bearings.

2. Reinstall valve lifters, rocker arms and self- lock-

ing rocker arm nuts.

3. Install rear and side access plates.

4. Reinstall cylinder head.

OIL PUMP COVER AND GEARS

Removal and Installation of Oil Pump

Cover and Gears

1.

Remove screws attaching oil pump cover assembly

to timing chain cover. Remove cover assembly and

slide out oil pump gears. See Figure 6A-44.

2. Wash off gears and inspect for wear, scoring, etc.

Replace any gears not found serviceable. Discard

pump covers scored by gear action. If pump housing

or distributor drive shaft bushing are worn (this is

only possible after a long service life), the timing case

together with all exchangeable pump parts have to be

discarded.

In isolated cases, timing cases are installed in pro-

duction having

.008

in. oversize bores for pump gears

and shafts. Oversize bores may exist either for one or

both gears; these timing cases are identified by the

number “0.2” stamped into pump flange on left and-

/or right-hand side. Oversize replacement gears

should be selected according to Part Catalog specifi-

cations.

3. Liberally lubricate spindles and gear teeth and use

new cover gasket. Install oil pump cover.

If new gears are installed, their end clearance in a dry

pump housing should be checked with a straight

edge and a feeler gauge. The gears must not protrude

more than X04 in. over pump housing. See Figure

6A-45.

FEELER

AUGE

STRAIGHT

I EDGE

Figure 6A-45 Checking Oil Pump Gear End Clearance

Loading...

Loading...