6E- 56 1973 OPEL SERVICE MANUAL

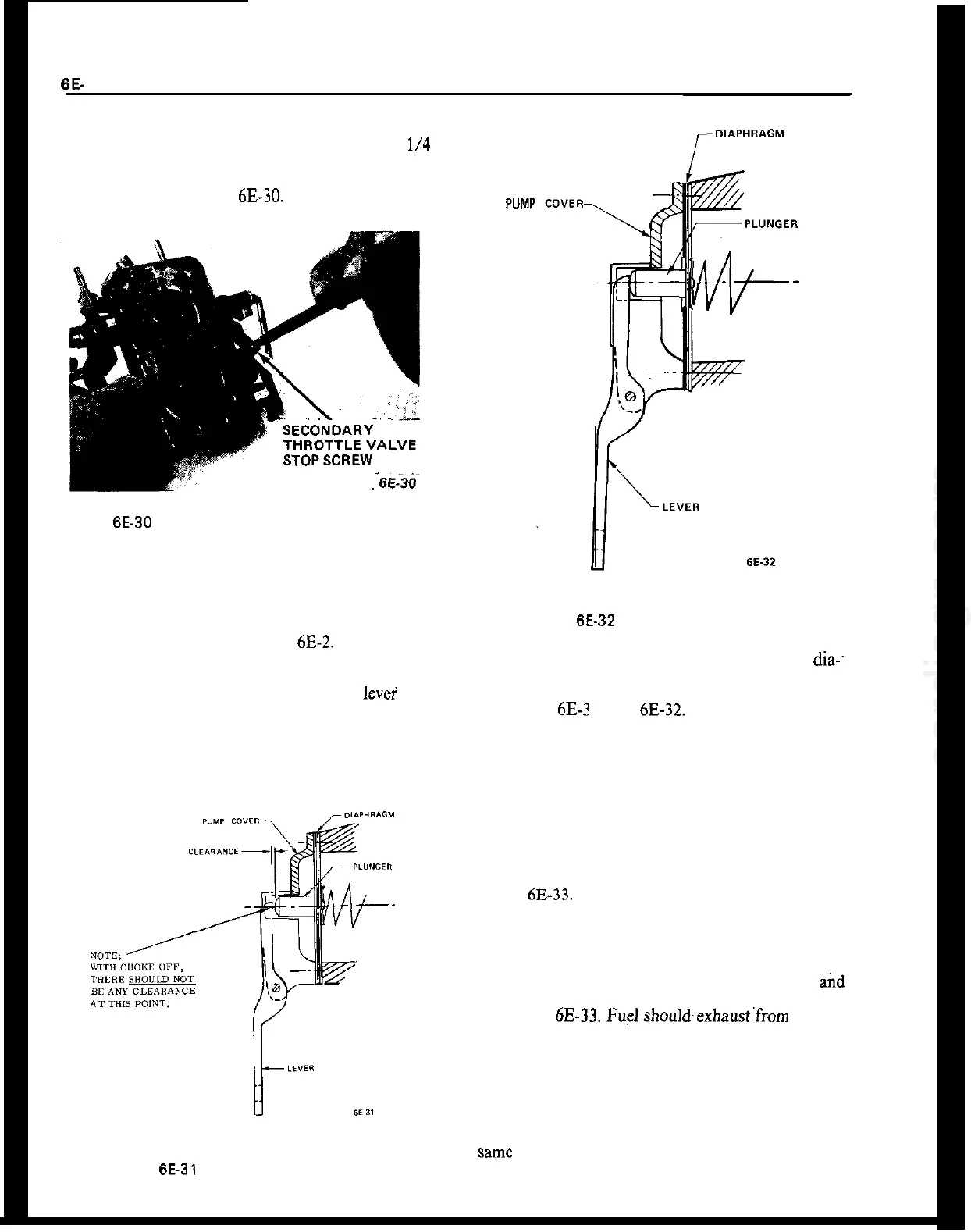

valve stop screw. Loosen the stop screw until the

valve is completely closed. Turn the screw in

l/4

turn from closed position, hold, and tighten lock nut.

This is done to insure that the throttle blade will not

stick closed. See Figure

6E-30.

PUMP

Figure 6E-30 Adjusting Secondary Throttle Valve Gap

24. Install accelerator pump connecting rod in lower

hole of primary throttle shaft lever and cotter pin in

outboard hole at accelerator pump actuating lever

end. Paying attention to proper arrangement of cot-

ter pin and washers. See Figure

6E-2.

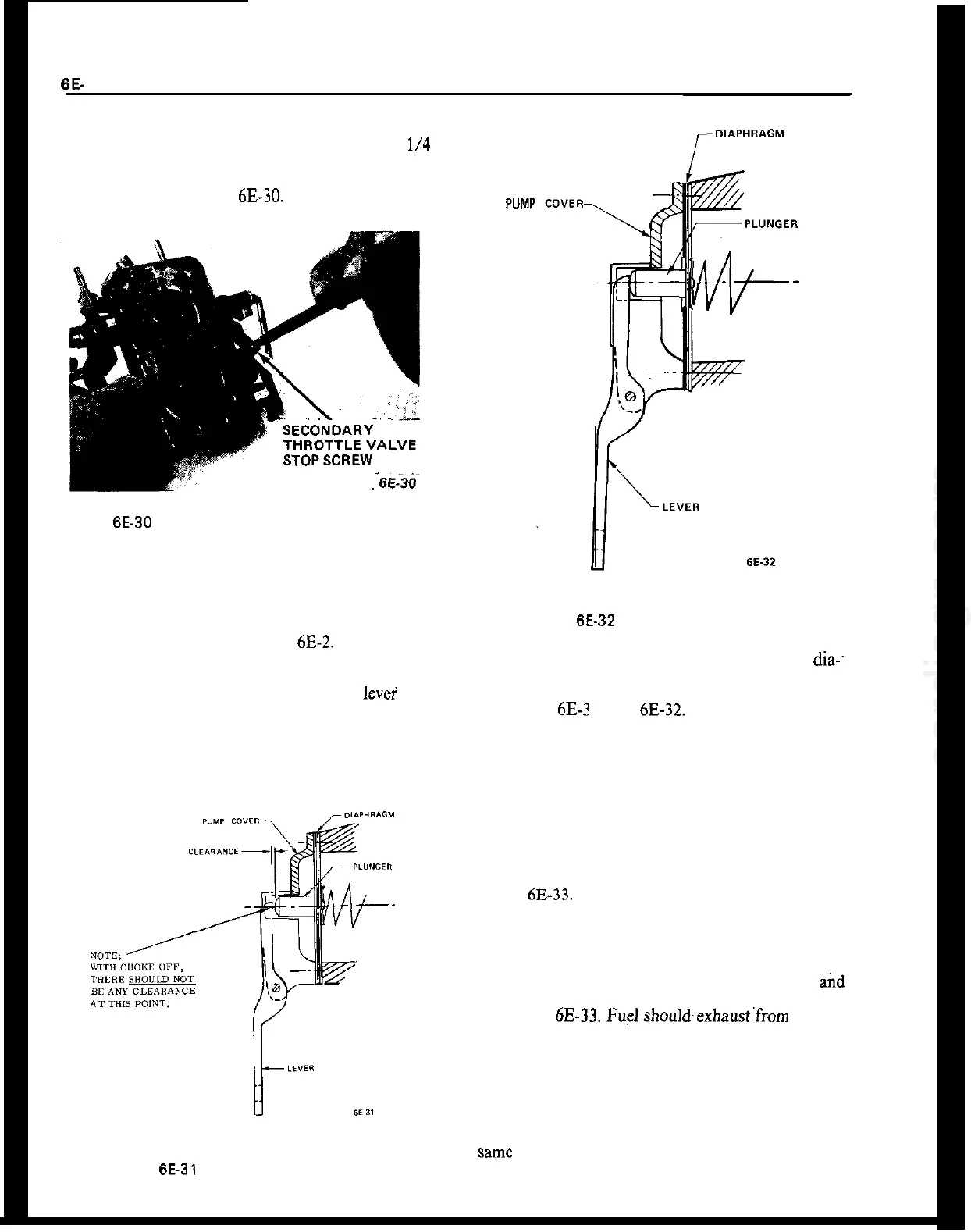

25. With throttle plate completely closed, there

should be no clearance between the pump levei and

the pump plunger rod.

26. If a clearance is present, loosen 4 accelerator

Figure

6E-31

Accelerator Pump Cover

Figure 6C32 Accelerator Pump Cover

pump cover retaining screws and allow the

dia-’

phragm spring to push plunger against lever so that

a zero clearance exists. Then retighten the screws.

See Figures

6E-3

1 and

6E-32.

27. Insert accelerator pump discharge nozzle so that

the bent tube end points into suction channel of the

primary barrel.

28. Fill the bowl with fuel.

29. With fuel in bowl, slowly open the throttle and

observe the accelerator pump pressure relief valve

exhaust ports and where it seats into the bowl. See

Figure

6E-33.

Fuel should not be bleeding back into

the bowl from the exhaust ports or where the relief

valve seats, but a steady stream of fuel should dis-

charge from the discharge nozzle.

30. With fuel in bowl, rapidly open the throttle atid

observe the exhaust ports of the pressure relief valve.

See Figure

6E-33.

Fuel should~exhaust’from the ac-

celerator pump pressure relief valve exhaust ports.

3 1. If the pressure relief valve malfunctions, remove

it and replace with a new one.

32. No float adjustment is possible, so check position

of float arm by comparing with a new float of the

same carburetor type. If float arm is bent, replace

float.

Loading...

Loading...