15

Maintenance

Warning!

Unplug the machine from electrical source and allow it to cool off before conducting maintenance.

Wear appropriate safety protection.

Note: To avoid unexpected downtime, keep up with maintenance schedule.

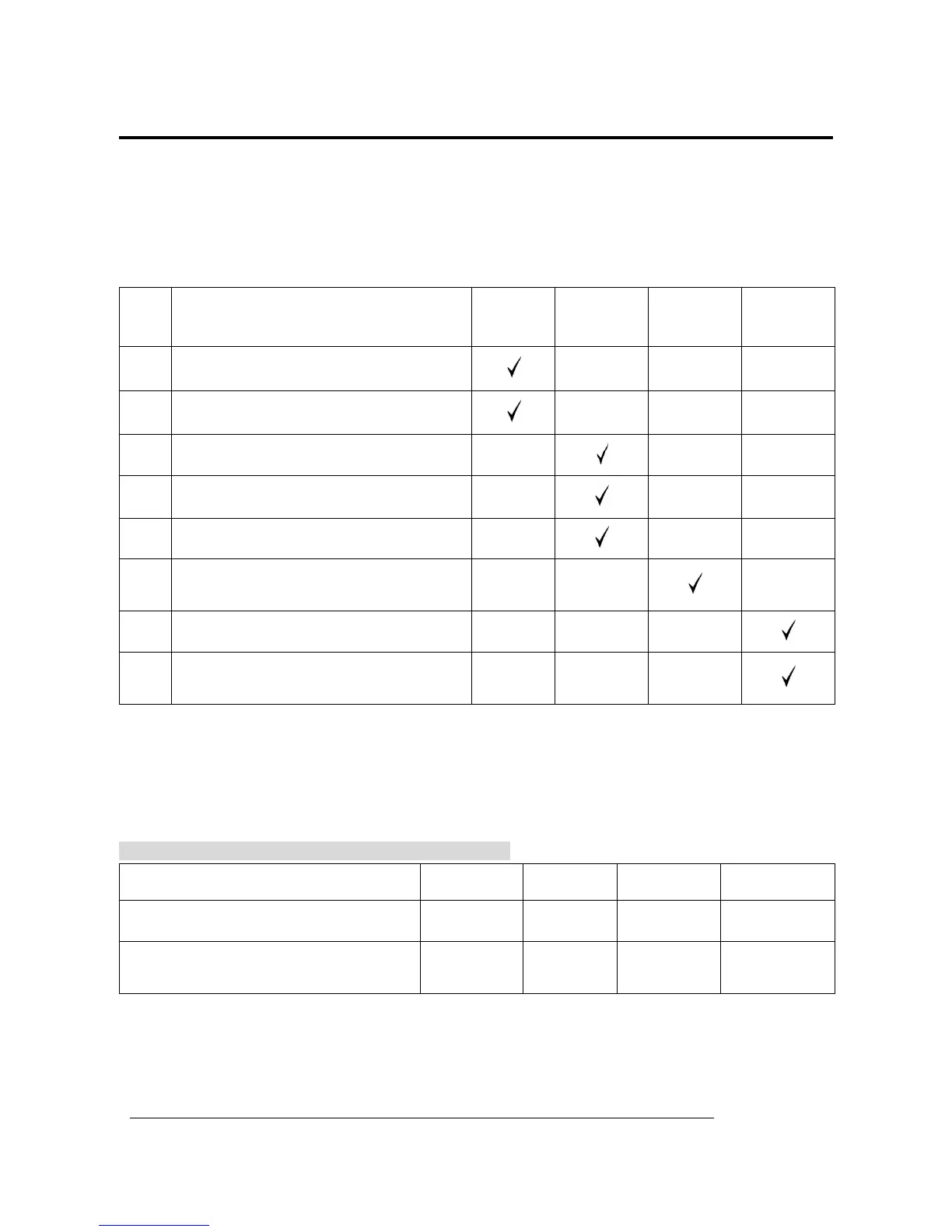

Maintenance Schedule

Maintenance Items Daily Monthly

vessel

C

Drain water and fuel tank

D

Check / replace water and fuel filter

E

*Check/clean water probe sensors

F

Clean/realign fuel nozzle and

electrodes

G

*Perform steam vessel de-scaling

H

Remove soot in the combustion

chamber

*The frequency of these maintenance items may vary based on the hardness of water in your area.

A. Add anti-scaling water treatment.

Add the recommended dosage of anti-scaling water treatment into the water tank. Use a TDS

meter to determine the hardness of water in your area. (See “Pre-start Procedure” Step #2 Page 7)

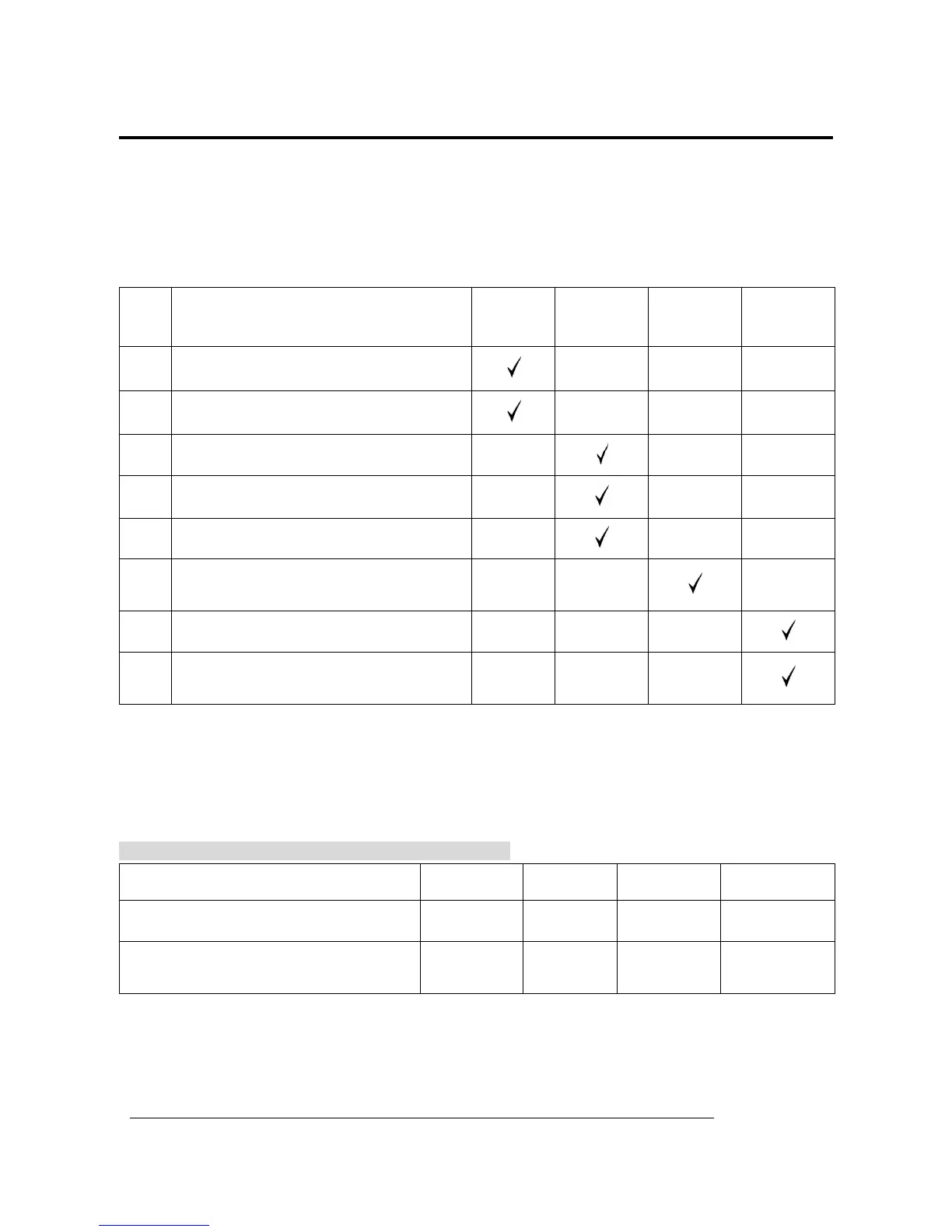

[Recommended Anti-scaling Water Treatment Dosage]

TDS Meter Reading (ppm)

0 - 40 40 – 120 120 - 425 425 - 1000

Hardness description Very Soft Soft Hard Very Hard

Dosage per every

100L (27gal) of water

No dose 25ml 50ml 100ml

Scale is caused by dissolved mineral in water settling on internal surfaces. Scale build-up can

greatly impact steam vessel longevity and operating efficiency. Adding anti-scaling water

treatment will help prevent scale from forming on the inside wall of the steam vessel and protect

against sensor malfunctions.

Only add water and manufacturer approved anti-scaling solution to the water tank.

Loading...

Loading...