Do you have a question about the Optimum Optiturn TU 2506 and is the answer not in the manual?

Explains the meaning and use of warning notices.

Contact information for the manufacturer.

Overview of safety warning symbols and warning signs.

Methods to prevent misuse of the lathe.

Identifies who the manual is addressed to.

Specifies who is permitted to operate the machine.

Outlines the company's responsibilities for staff training.

Details the operator's responsibilities.

Specifies extra requirements for electrical work.

Describes the lockable main switch function.

Explains the protective cover and its safety switch.

Details electrical connection specifications for models.

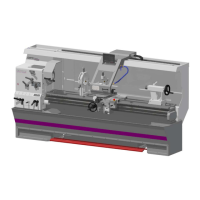

Lists technical specifications of the machine.

Provides dimensions of the machine's working area.

Information on checking the delivered machine parts.

Guidelines for safe transport and handling of the machine.

Criteria for selecting a suitable installation location.

Steps for assembling synchronous belt on specific models.

Steps for assembling synchronous belt on TU 2506 V.

Procedure for installing and tensioning the V-belt.

Procedure for warming up the machine before operation.

Instructions for cleaning and lubricating machine parts.

What to check during a visual inspection.

Steps for performing functional tests.

Guidance on connecting the electrical supply.

Detailed steps for mounting the chuck flange.

Steps to change the speed range of the lathe.

How to use selector switches for feed direction and speed.

How to turn short tapers using the top slide.

Method for turning tapers using the tailstock.

Techniques for precise cone turning.

Method for turning tapers by offsetting the tailstock.

Identifies and describes the machine's controls and indicators.

Identifies and describes the machine's controls and indicators.

Safety precautions for maintenance and repair work.

Steps to take before starting maintenance.

Legal notice regarding document copyright.

Definitions of technical terms used in the manual.

Records of manual revisions and updates.

Diagram and details for the top slide spare parts.

List of spare parts with item numbers for TU2506.

Diagram and details for the top slide spare parts.

List of spare parts with item numbers for TU 2807.

Wiring diagram for TU 2506 model at 230V.

Wiring diagram for TU 2506/TU 2807 models at 400V.

Wiring diagram for TU 2506 V/TU 2807 V models.

Alphabetical listing of topics covered in the manual.