11

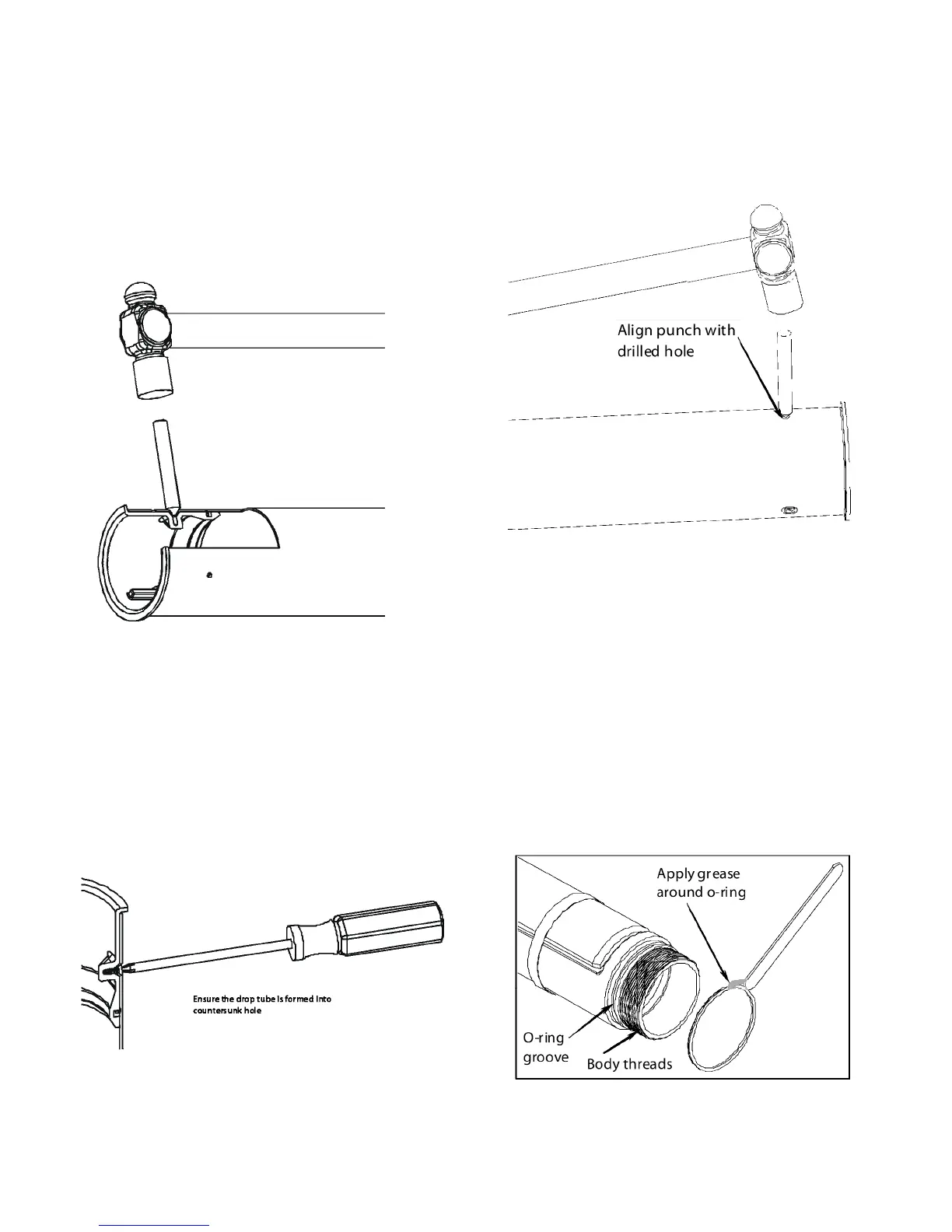

STEP 13: DIMPLE FIRST HOLE

Remove tool. Remove any chips or burrs from the drill-

ing operation. Place the assembly on a solid surface.

Using the punch supplied with the 71SO-TOOL, 71SO-

TOOLC, and 71SO-TOOLCT, align the tip of the punch

with the drilled hole and dimple the upper drop tube by

striking the punch with a hammer until the drop tube is

formed into countersunk hole in the inlet tube. After

punching, remove any chips that may have fallen into

the inlet tube screw hole.

STEP 14: ASSEMBLE FIRST SCREW

Ensure that the drop tube was formed into the counter-

sunk screw hole as shown in Figure 14 if not return to

Step 13. Apply black moly grease to screw and tighten

rst screw into inlet tube with a screwdriver. Use only

the taptite screws that are supplied with the unit. Seat-

ing torque is 20 in-lbs min. to 35 in-lbs max. Screw head

should be ush with the drop tube. Do not over tight-

en.

STEP 15: DIMPLE REMAINING HOLES

Remove any chips or burrs from the drilling operation.

Dimple the next (2) holes as done in Step 13. Make sure

the assembly is on a solid surface when punching. After

punching, remove any chips that may have fallen into

the inlet tube screw hole.

STEP 16: ASSEMBLE OTHER SCREWS

Apply black moly grease to screws and tighten the oth-

er (2) screws into inlet tube with a screwdriver as done

in Step 14. Use only the taptite screws that are supplied

with the unit. Seating torque is 20 in-lbs min. to 35 in-

lbs max. Do not over tighten.

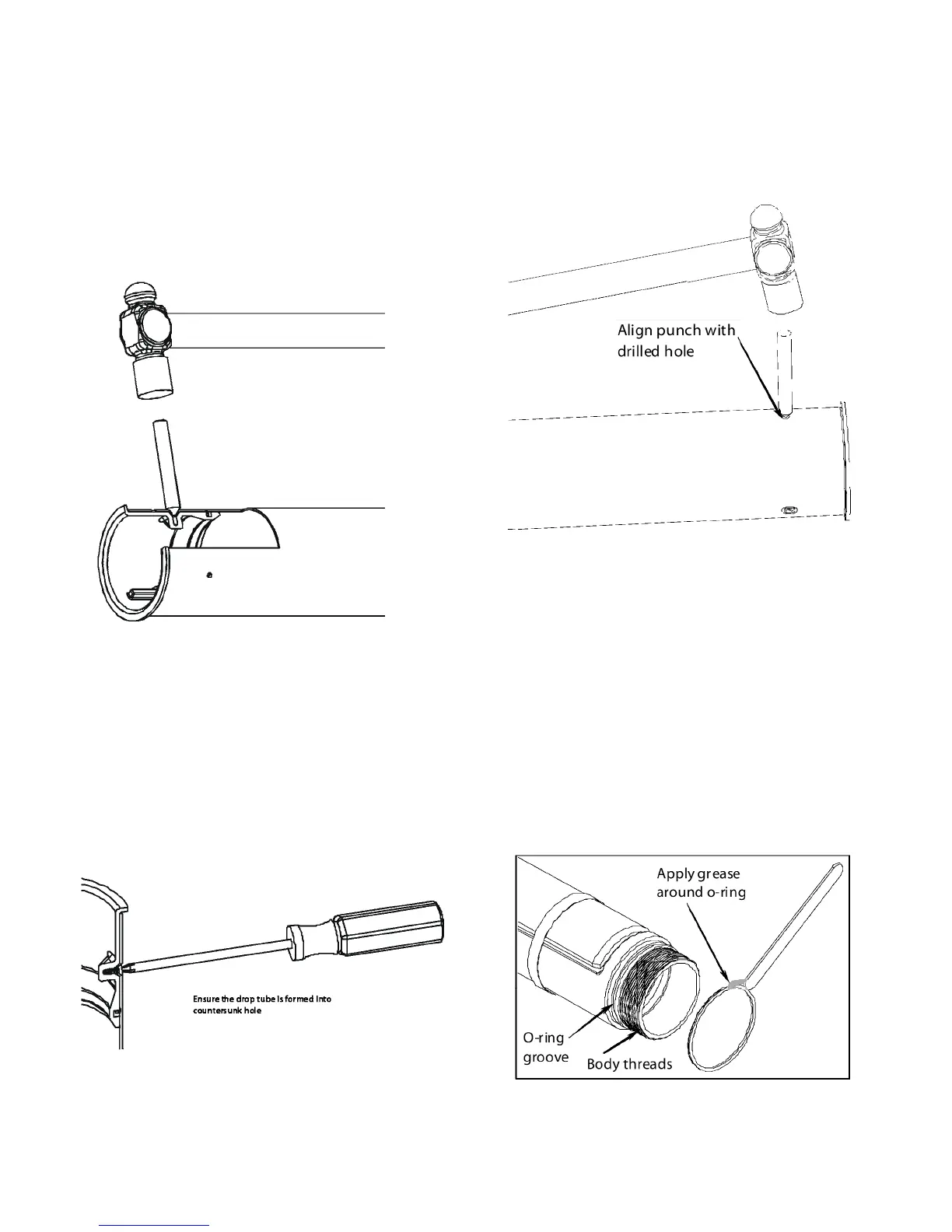

STEP 17: APPLY GREASE TO LOWER O-RING AND

BODY THREADS

Apply black moly grease to the lower tube o-ring and

body threads as shown. Make sure coverage is com-

pletely around the o-ring. Install o-ring in groove just

above threads.

Figure 13

Figure 14

Figure 15

Figure 17

Loading...

Loading...