14

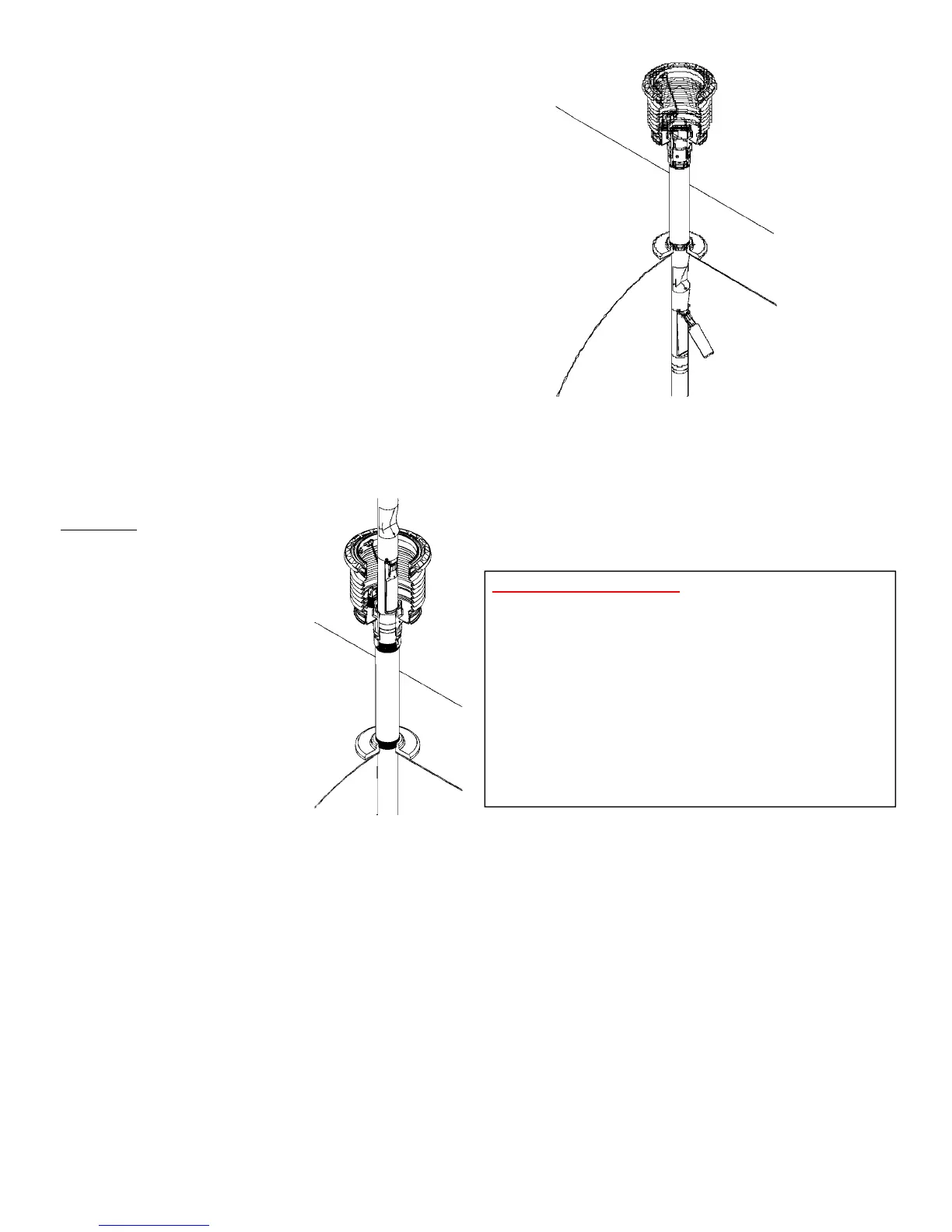

STEP 20: PREPARE FILL RISER FOR VALVE INSERTION

IMPORTANT: Inspect the riser pipe for any foreign ma-

terial. Over spray from tank relining or any internal

burrs inside of pipe must be removed prior to installa-

tion. Failure to have an unobstructed riser pipe may

prevent proper installation or operation of the valve.

Thoroughly clean top of riser pipe.

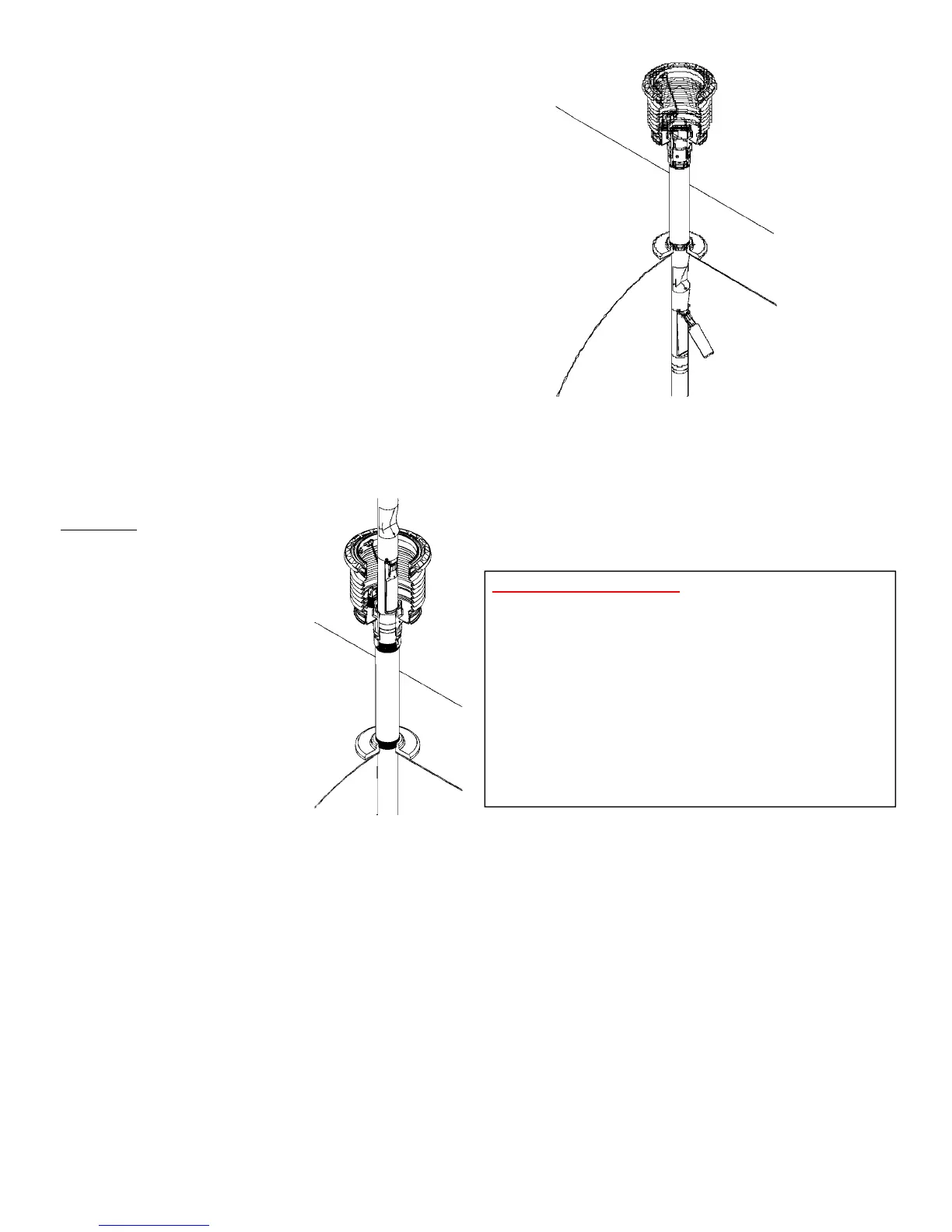

STEP 21: REMOVE ELASTIC BAND

Remove the elastic band securing the oat to the valve

body. The oat will move into an outward position.

STEP 22: INSERT DROP TUBE

Make sure the upper O-Ring gasket is under the ange

of the inlet tube. Hold the oat down against the valve

body and slowly insert the drop tube overll valve into

the riser pipe. Do not force valve into the riser pipe. If

any obstruction or foreign matter interferes with

smooth insertion of the valve, the riser pipe must be

cleared.

WARNING

Failure to follow the assembly

and installation instructions or

use of excessive force to insert

the OPW 71SO will VOID THE

WARRANTY.

Diculty in removing the existing

ll tube (if there is one) means

there may be an obstruction in the

riser pipe. Look for burrs, defor-

mations, excess tank lining materi-

al or other projections that may

interfere with easy insertion of the

OPW 71SO. The 71SO is designed

for insertion into schedule 40 pipe. If

schedule 80 pipe has been used for the

riser, the 71SO cannot be installed. If seamed pipe has

been used, the internal weld bead may interfere with

the OPW 71SO and prevent installation. If the OPW

71SO won’t slip in easily DON’T FORCE IT! Damage to

the valve may result if excess force is used. Examine the

riser pipe carefully; determine the nature of the obstruc-

tion; take appropriate steps to remove it.

STEP 23: CHECK INSTALLATION

Insert the drop tube all the way into the tank until the

ange and gasket seat onto the top of the Face Seal

Adaptor. The oat will swing out into the operating

position as it passes into the tank.

Make sure that the oat is aligned along the length of

the tank. The length of the tank can easily be deter-

mined by locating other manholes or pump boxes that

are installed around other tank ttings. Look into the

drop tube and align the deector with the length of the

tank.

For testable models only: Unthread the socket adap-

tor assembly from the inlet tube (a 3/8” square drive

extension will attach to the socket adaptor, secure all

tools to ensure they don’t fall into the tank or valve) and

ensure oat and poppet move freely when socket adap-

tor assembly is pulled on. When looking down into the

upper tube ensure poppet is visible when socket adap-

tor is pulled and resets properly when socket adaptor is

released. See page 17 for full testing details. If poppet

does not actuate freely take appropriate steps to correct

before proceeding.

CAUTION: No obstruction in the tank can be within

14" from the center of the riser pipe or the valve

may not operate properly (See Figure 24).

STEP 24: ALIGN VALVE

Install the OPW Jack Screw Kit and a 4" NPT nipple to

lock the valve in place. Refer to the Installation Instruc-

tions supplied with the Jack Screw Kit. For testable

models ensure that the socket adaptor is aligned so

it does not interfere with the jack screw kit. (see Fig-

ure 24A). Install the Rotatable Product Adaptor (Refer

to Installation Instructions supplied with the Product

Adaptor.) Make sure that the valve does not rotate

while tightening the adaptor by observing the position

of the deector. The valve must remain aligned

along the length of the tank as in Step 23. Repeat

this step as necessary to assure proper valve alignment.

Figure 22

Figure 23

Loading...

Loading...