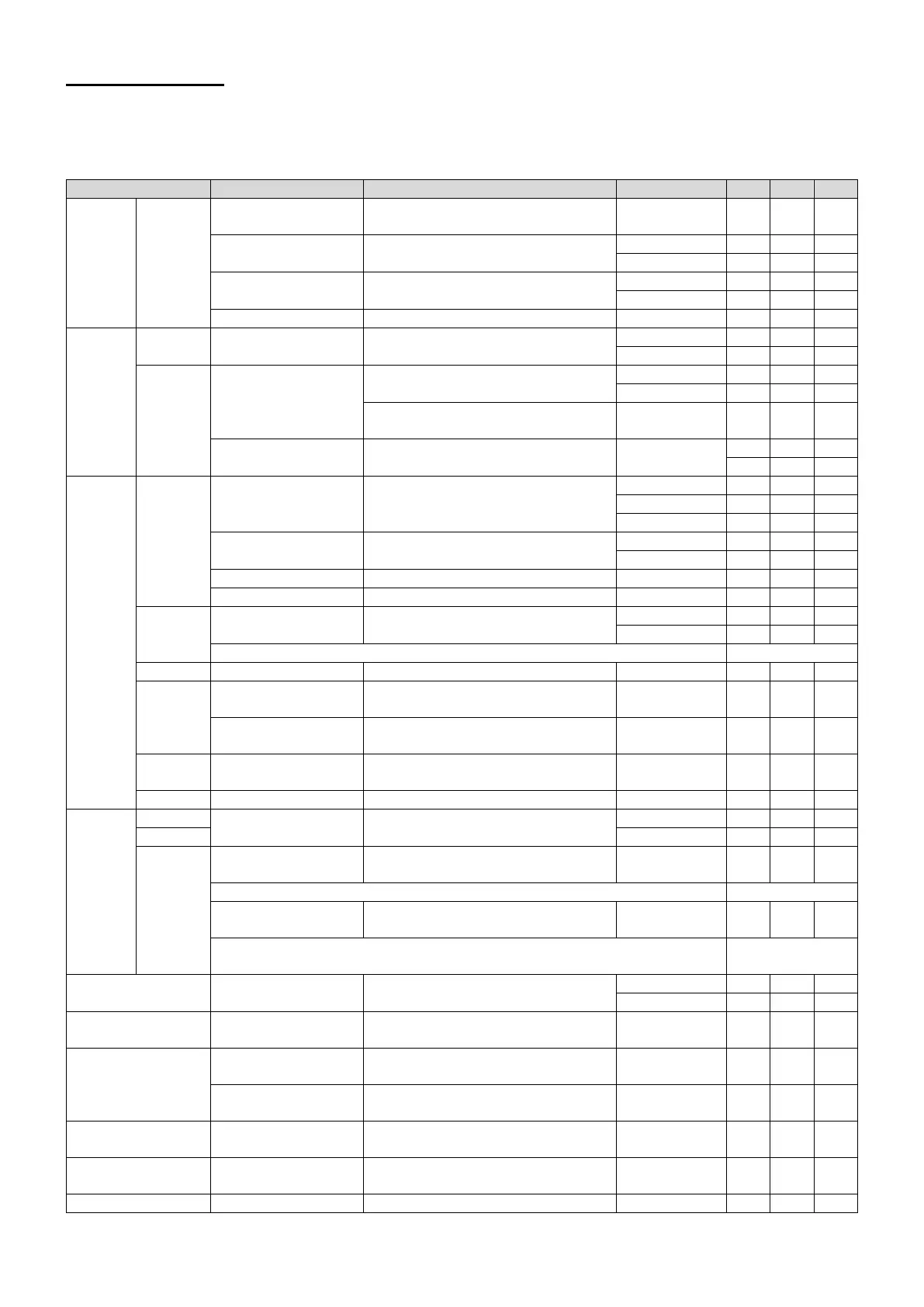

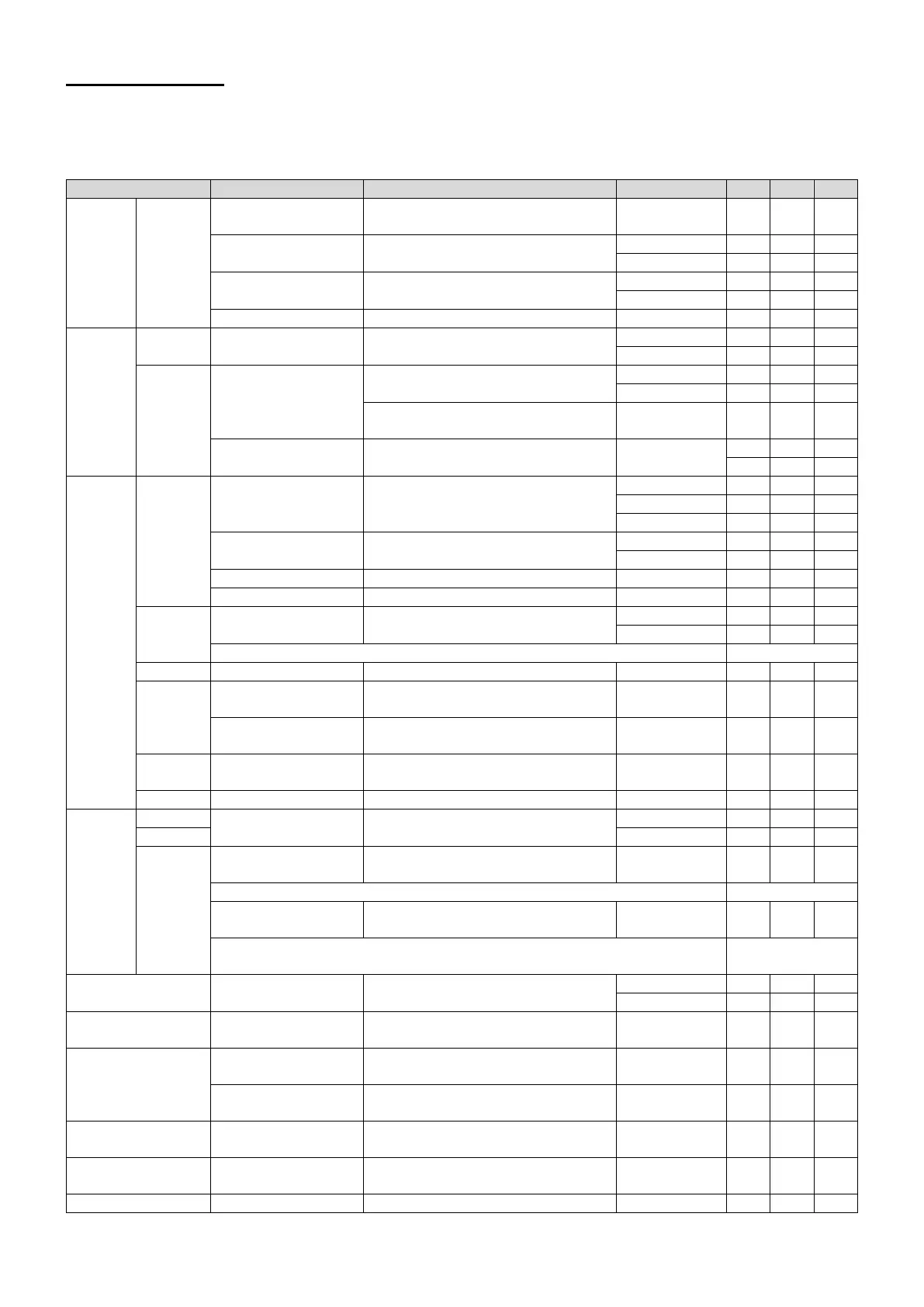

OREC RM60W

MAINTENANCE CHART

Lack of inspection or maintenance leads to accident or trouble of machine. In order to ensure the good

performance and safe condition of machine, make inspection referring the table below.

About the frequency of maintenance, refer the indication D(daily), M(monthly), and Y(yearly).

device

part

Bend, clack or corrosion.

Setting of flapper rubber.

part

setting

Looseness, wear, and loss of bolt

and nut

Performance of brake

(to stop in 5 seconds)

body

exhaust, choke

Smoothness of accelataion, color

of exhaust gas, smell, smoothness

Setting looseness, corrosion,

charging status of battery

Engine setting looseness or clack

Quantity, quality, leak or mixing of

obstacle, replacing period

Engine oil : First 5h, later at every 50h, Filter : at every 100h

Leak, deformation, and clogging

Clack on insulator, carbon

between terminal

High voltage cord,

plug cap

Degradation, clack and split on cap

Grass remain inside the housing or

not

mission

Tension, clack, damage or dirt

mission,

HST

Quantity, quality, leak mixing of

obstacle(water, air)

Transmission oil : first 20h and later each 100h

Quantity, quality, leak mixing of

obstacle(water, air)

refere to instruction manual, later at each 200h

including replacement of oil filter.

Movement of lever

and wire

Movement is smooth or not.

Proper movement, N position, and

looseness

Proper air pressure, damage or

wear

Looseness, wear, and loss of bolt

and nut

Looseness, wear, and loss of bolt

and nut

Indication of correct hour, proper

displaying

Attachment of label, damage or dirt

Loading...

Loading...