11

ASSEMBLY

CAUTION:

Always be sure that

the tool is switched off and the battery

cartridge is removed before carrying out

any work on the tool.

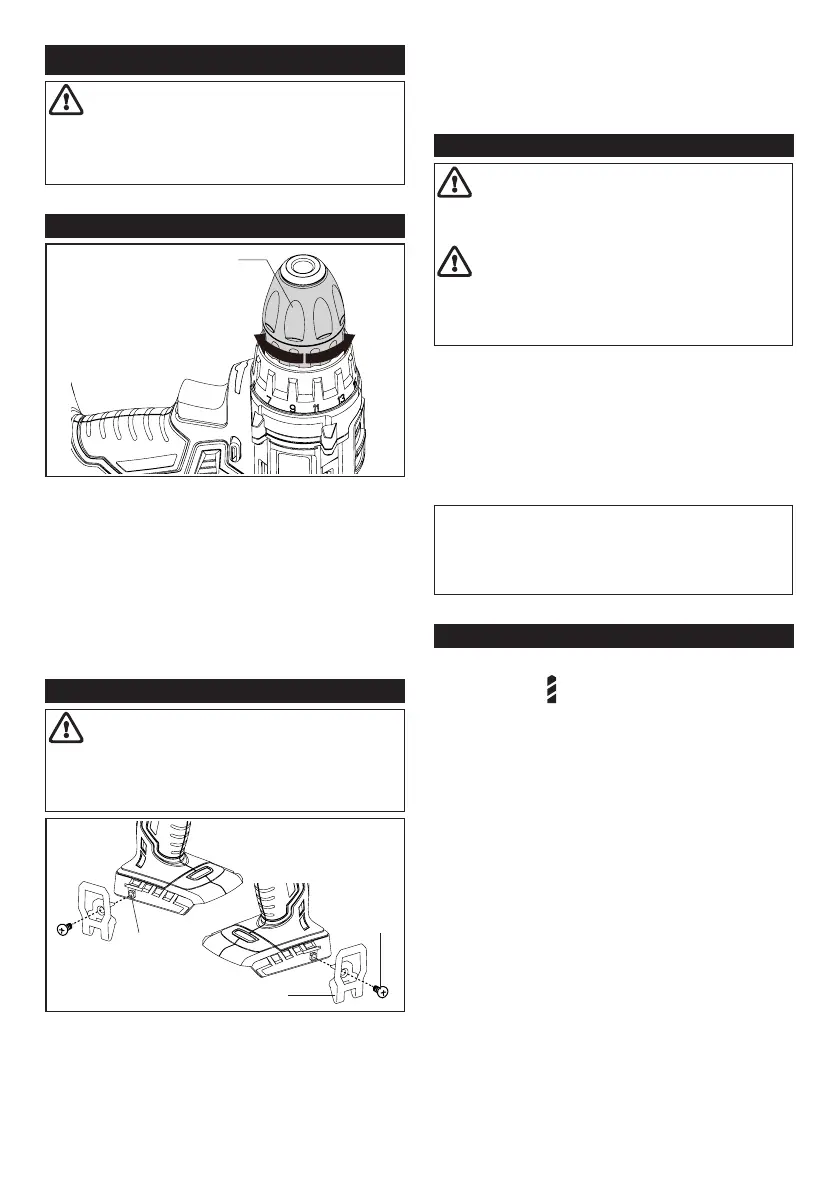

Installing or removing driver bit/ drill bit

1

2 3

1. Sleeve 2. Close 3. Open

Turn the sleeve counterclockwise to open

the chuck jaws. Place the driver bit/drill bit

in the chuck as far as it will go. Turn the

sleeve clockwise to tighten the chuck. To

remove the driver bit/drill bit, turn the sleeve

counterclockwise.

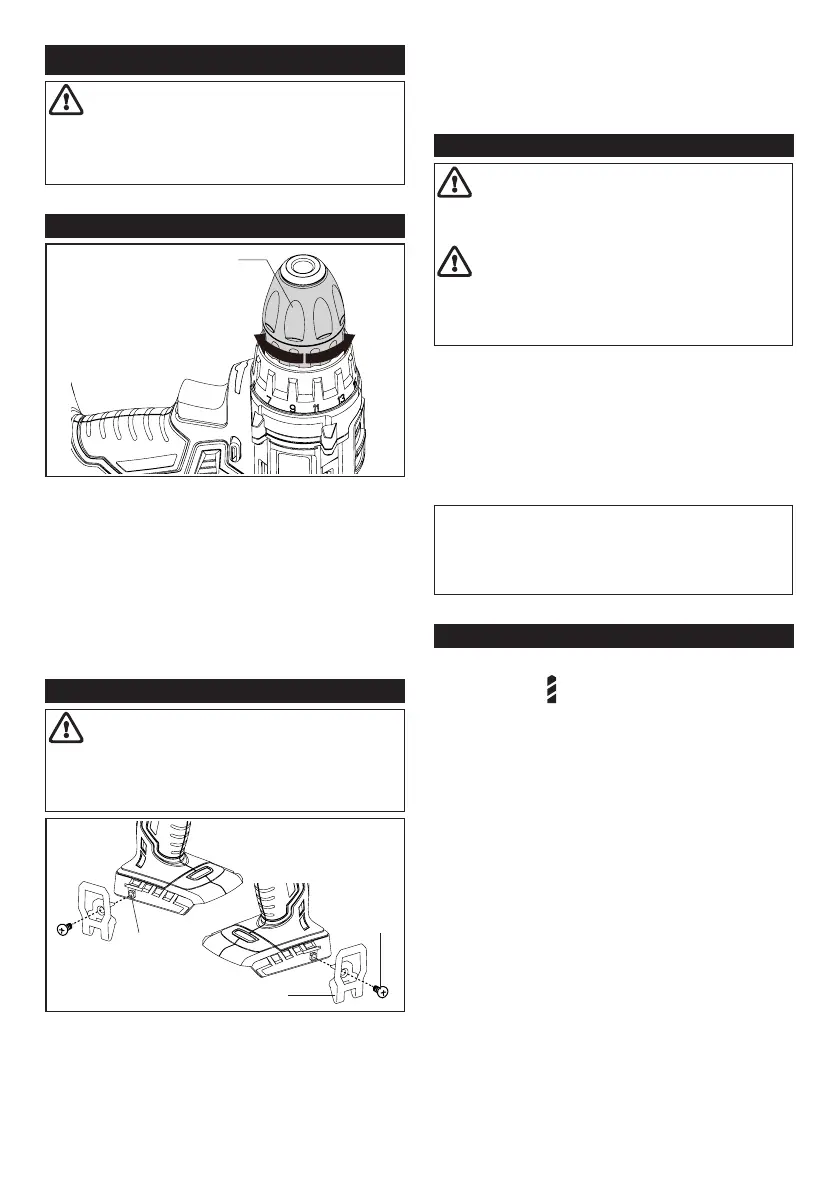

Installing hook

CAUTION:

When installing the

hook, always secure it with the screw

firmly.

If not, the hook may come off from

the tool and result in the personal injury.

1

3

2

1. Groove 2. Hook 3. Screw

The hook is convenient for temporarily

hanging the tool. This can be installed on

either side of the tool. To install the hook,

insert it into a groove in the tool housing on

either side and then secure it with a screw.

To remove, loosen the screw and then take it

out.

Screwdriving operation

CAUTION:

Adjust the adjusting

ring to the proper torque level for your

work.

CAUTION:

Make sure that the

driver bit is inserted straight in the screw

head, or the screw and/or driver bit may

be damaged.

Place the point of the driver bit in the screw

head and apply pres- sure to the tool. Start

the tool slowly and then increase the speed

gradually. Release the switch trigger as soon

as the clutch cuts in.

NOTE:

When driving wood screw, pre-drill

a pilot hole 2/3 the diameter of the screw. It

makes driving easier and prevents splitting

of the workpiece.

Drilling operation

First, turn the adjusting ring so that the arrow

points to the marking. Then proceed as

follows.

Drilling in wood

When drilling in wood, the best results are

obtained with wood drills equipped with

a guide screw. The guide screw makes

drilling easier by pulling the drill bit into the

workpiece.

Drilling in metal

To prevent the drill bit from slipping when

starting a hole, make an indentation with a

center-punch and hammer at the point to be

drilled. Place the point of the drill bit in the

indentation and start drilling.

Use a cutting lubricant when drilling metals.

The excep- tions are iron and brass which

should be drilled dry.

Loading...

Loading...