Sheet No.

Issue Date: Rev. C, April 3, 2019

© Bosch Automotive Service Solutions Inc.

Parts List & Operating Instructions Form No. 545622

Safety Precautions

CAUTION: To prevent personal injury and/or damage to the equipment,

• Study, understand, and follow all instructions before operating this clutch handler.

• Wear eye protection that meets ANSI Z87.1 and OSHA standards.

• Wear steel-toe shoes that meet ANSI Z41 and OSHA standards.

• If the operator cannot read English, operating instructions and safety precautions

must be read and discussed in the operator’s native language.

– Si el operador no puede leer inglés, las instrucciones de operación y las

precauciones de seguridad deberán leerse y comentarse en el idioma nativo del

operador.

– Si l'utilisateur ne peut lire l'anglais, les instructions et les consignes de sécurité

doivent lui être expliquées dans sa langue maternelle.

• Inspect the clutch handler before each use. Do not use the clutch handler if damaged,

altered, or in poor condition.

• Never exceed the rated lifting capacity of the clutch handler.

• Never move the clutch handler with the load any higher off the ground than necessary.

• Use clutch handler on a hard, level surface.

• Move the clutch handler cautiously around corners to avoid tipping.

• Lowering the lift arm too quickly could cause equipment damage. SLOWLY turn the

hydraulic control valve counterclockwise to release hydraulic pressure.

• Use only those adapters and replacement parts provided by the manufacturer.

• Never modify the unit or adapters.

• Stay clear of the clutch handler’s pinch points as you raise and lower the lift arm.

• Use only approved hydraulic fluid.

Assembly Instructions

(Item numbers refer to the parts list illustration.)

1. Bolt legs (Item #3) to handler using three cap screws (#26),

one threaded handle holder (#29), four washers (#27), and

nuts (#28).

2. Bolt swivel casters (#35) to legs using four washers (#2)

and nuts (#1).

3. Thread two cap screws (#14) through upper lift arm and

tighten.

4. Thread adjusting screw (#5) into upper lift arm.

5. Free up swivel bearing in upper lift arm by applying a

penetrating lubricant to race and working bearing up and

down and side-to-side with a punch or screwdriver.

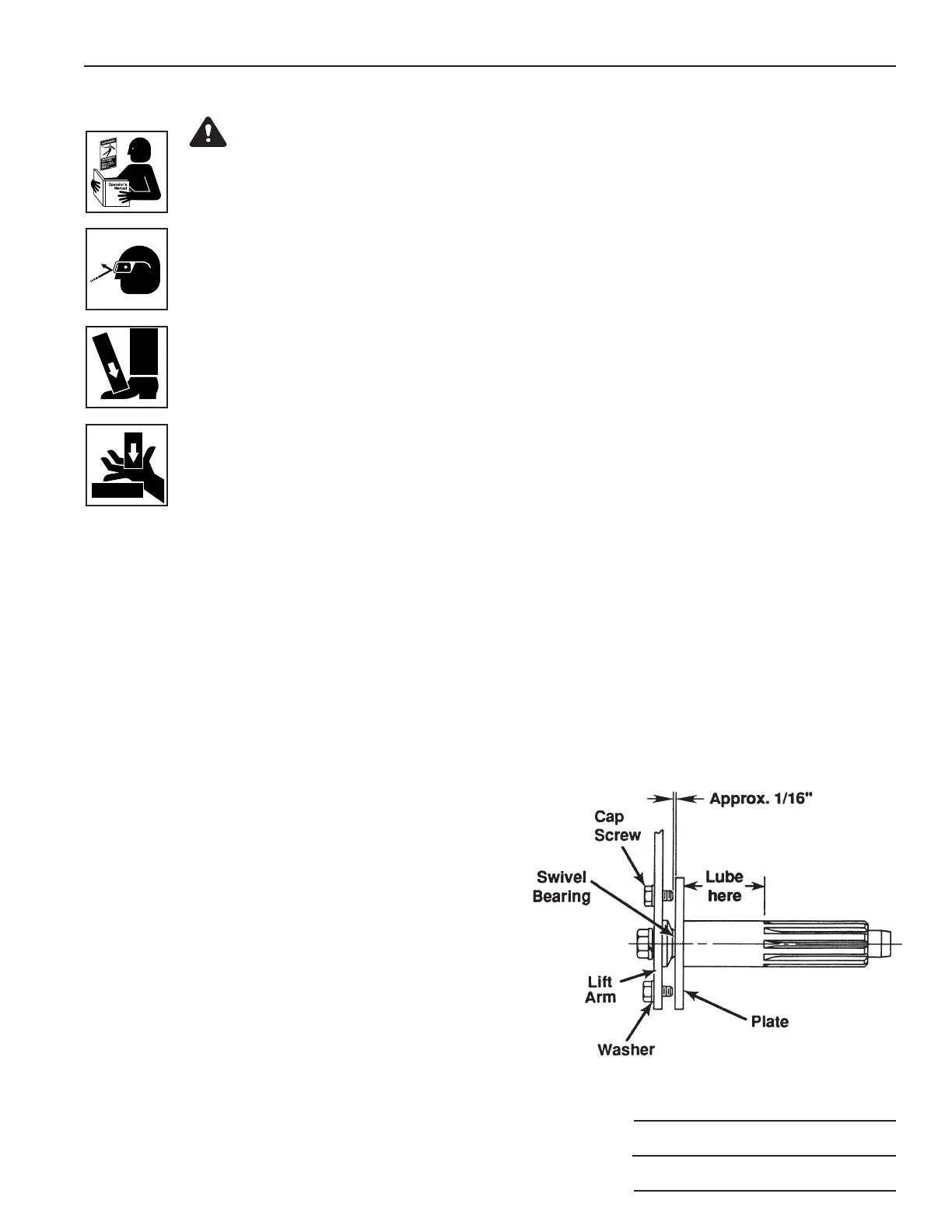

6. Insert one cap screw (#17) with washer (#18) through swivel

bearing in upper lift arm. Slide plate (#15) over cap screw.

Thread splined shaft (#16) onto cap screw and tighten.

7. Measure distance between plate (#15) and cap screws

(#14). If distance is less than 1/16", remove two cap screws

(#14), and insert a washer (#7) between each cap screw

(#14) and upper lift arm. Wrench tighten. See Figure 1.

Figure 1

2 of 3

Loading...

Loading...