W

ATER DISPLACEMENT METHOD (QUANTITATIVE)

The first step is to thoroughly wet the membrane with water

assuring that each pore is filled with liquid. Once the membrane

is thoroughly wetted, the feed/retentate flow path is drained.

A graduated cylinder is filled with water and carefully turned

upside down in a beaker full of water. The end of the filtrate

tube is placed inside the graduated cylinder. The retentate

port is then closed off. The system is pressurized to about

10 psig (0.7 bar) through the device feed port. Air will

diffuse through the membrane, exiting through the filtrate

tubing and into the graduated cylinder. The amount of air

displaced over time is measured in mL/min. This is the air

diffusion (forward flow) integrity test value.

Initially water in the filtrate line will be displaced. Wait until air

starts to flow before taking any measurement, as any water

left in the feed channel will first pass across the membrane.

The membrane creates a barrier to air flow, not water flow.

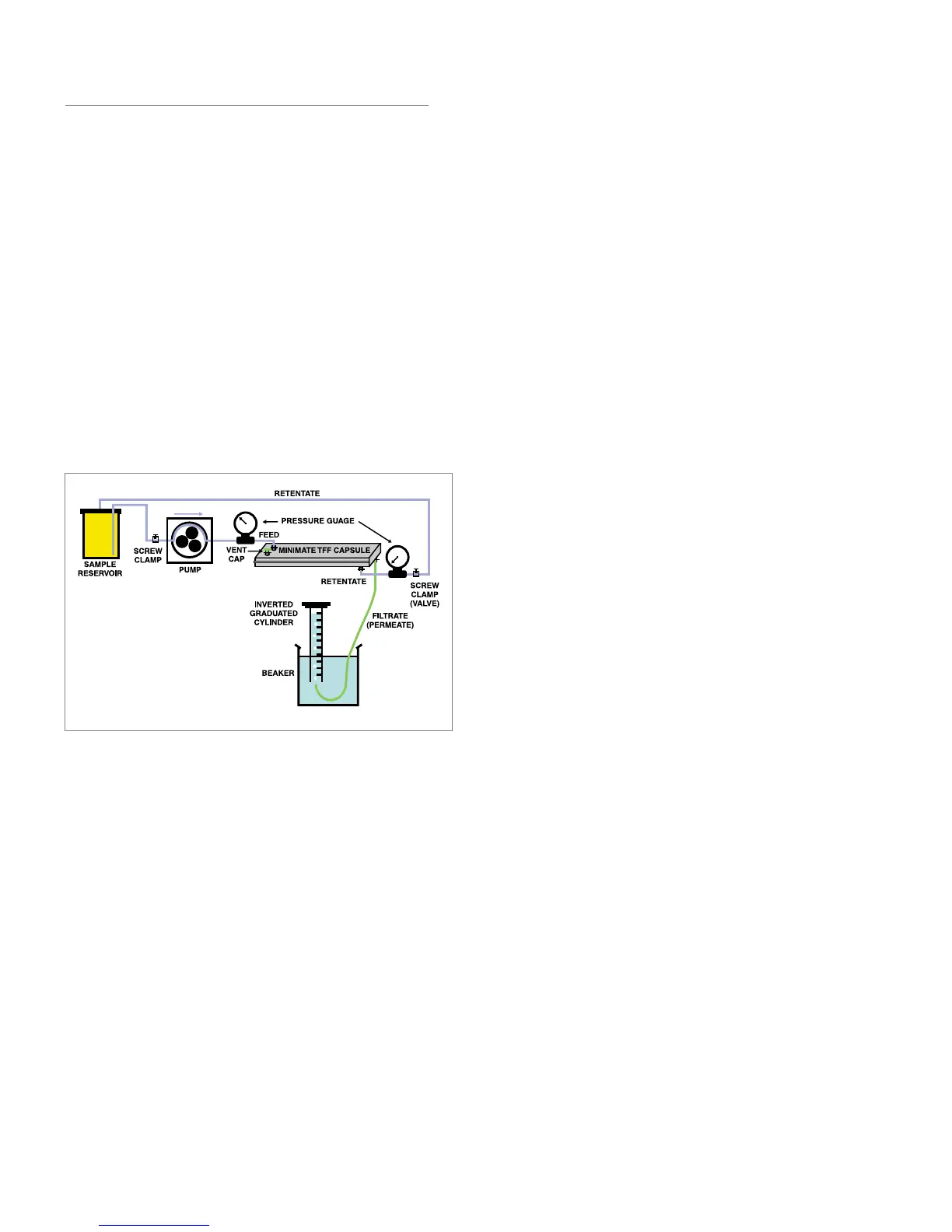

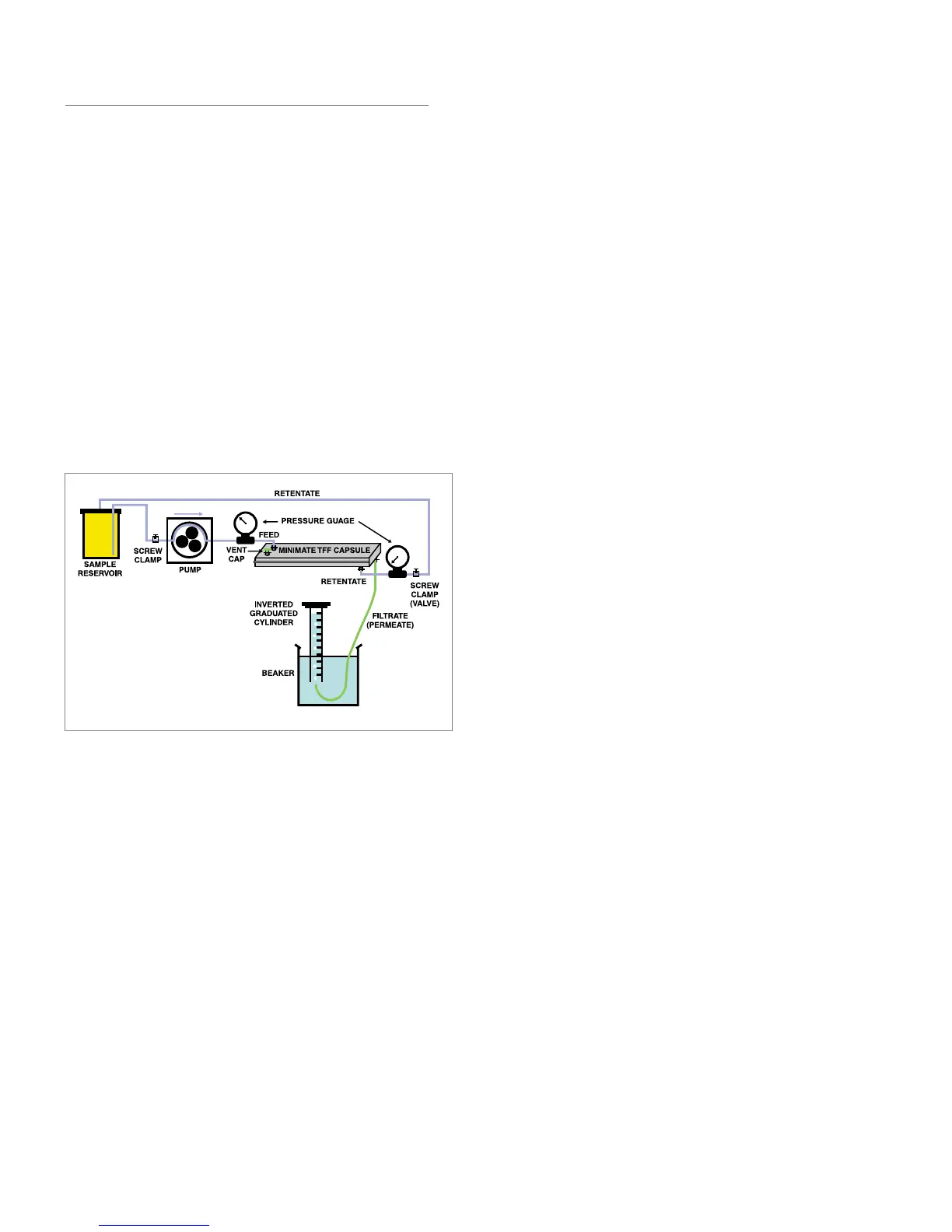

Figure 2

Set-up for Air Integrity Testing of Minimate TFF Capsule

This protocol describes performing the procedure using a

peristaltic pump to generate airflow. For more accurate testing,

a regulated, compressed air or nitrogen supply should be used.

Forward Flow Air Integrity Test Procedure:

1. Empty the feed reservoir.

2. Open retentate and filtrate screw clamps and pump out

liquid from feed and retentate tubing.

3. Fill a 400 mL or larger beaker and a 25 mL graduated

cylinder with water.

4. Invert the full graduated cylinder into the large beaker.

(Place a piece of paper or Parafilm over the mouth of

the cylinder. Turn the cylinder over and remove the

piece of paper after the mouth of the cylinder is below

the water level in the beaker.) The cylinder should

remain filled with water.

5. Place the end of the filtrate tubing into the beaker.

The filtrate tube should be open.

6. Slowly turn up the pump speed to give a retentate flow

rate of 40 mL/min. Tighten the retentate screw clamp to

apply a feed pressure of 10 psi.

7. Watch for bubbles emerging at the end of the filtrate

tube. When the flow seems to be consistent, place the

end of the filtrate tubing into the inverted cylinder. The

cylinder can now rest on the bottom of the beaker.

Make sure that the filtrate tubing is not crimped under

the cylinder mouth.

8. Measure the amount of air entering the graduated

cylinder for sixty seconds (mL/min). Compare to integrity

specifications for the Minimate TFF capsule

9. If no air bubble reaches the cylinder within 3-5 minute,

the device is most likely within specifications. (Calculate

the volume in the filtrate tubing and compare to the

allowable airflow rate to see if sufficient waiting time has

been allowed.)

www.pall.com/lab

11

Loading...

Loading...