d. R410A refrigerating machine oil

Conventionally, mineral oil or a syntheti c oil such as alkylbenzen e ha s been used for R22 refrigerating ma chine

oil. Be caus e of the poo r compatibility betwe en R 410 A and conve ntional oils l ike m ine ral oil, h owe ver, ther e is a

te n de ncy for th e re fr i g er at i ng m a ch in e o il to co l le c t in the ref rigerating cy c le. F or thi s reason, polyester and

oth er s ynth etic oils whic h ha ve a high compa tibility w ith R 4 10 A a r e used a s refrige ratin g m achine o il.

Because of the hig h hygro scop ic p roperty of s yntheti c oil, more care must be t ake n in its hand ling tha n was

necessary with conventional refrigerat ing mac hine oils. Also, these sy nthe tic oils will degrade if m ixed with

mi nera l oil o r a lkylbe n zene , ca usin g cl oggi ng i n ca pil lary t ubes or compr es sor mal func tion. D o not mix t he m

unde r any c i rc u mstance s.

10.1.2 Safety Measure When Installing / Receiving Refrigeran t Piping

Cause the gas pressure of R410A is a pproximately 1.6 tim es as hi gh a s that o f R2 2, a mistake in insta llation or

servicing c oul d r es ul t in a major acci dent . It i s essen tia l tha t you u se R 41 0 a too l s and m ate r i als, and t ha t you

observe the fol lowi ng p recautions to ensure safety.

Do not u se a ny refrigerant other than R410A in Acs that have been used with R410A.

If a ny re fr ig e r ant g as lea k s w h il e yo u are wo rk in g , ve nt il a te th e ro o m. Toxi c g a s may b e ge n er at ed if refri g er an t

gas is exposed to a d irect flame.

When instal ling or transferring an A C, d o not allow any air or sub stance other than R410A to mix into the

refri geration cycle. I f it does, the p ressure in the r efrigeration cycle can b ecome abnormally high, possibly

causing an explosion and/or injury.

Afte r finishi ng the installation, check t o make sure there is no refrigerant gas leaking.

When installing or transferrin g an AC, follow the instructions in the i nstallation instructions caref ully. Incorrect

installation can r esult in a n ab nor mal refri geration cycl e or wat er leakage, elect ric s hock, fire, etc.

Do not perform any alterations on the AC unit under any ci rcumstances. Have all repair work do ne b y a spec ialist.

Incorrect repairs can result in an water leakage, electric shock, fire, etc.

10.2. TOOL FOR INSTALLING / SERVICING REFRIGERANT PIPING

10.2.1

Necessary Tools

In ord er to preven t an R41 0AA C fr o m m i st a ken ly b e ing c ha r ged wi th any oth e r refrigerant, the diamet er of the 3-way

valve service port on the outdoor unit has been changed.Also, to increase its ability to withstand pressure, the

oppo sing dimensions have be e n c h an g ed fo r t he refrigerant pip e fl a r ing s ize and f lar e nut. A ccor di ngly, w hen

instal li ng or servicing r efrigerant pipin g , you m u st h a ve b ot h the R410A and ordinar y tools li sted below .

1.

2.

3.

4.

5.

6.

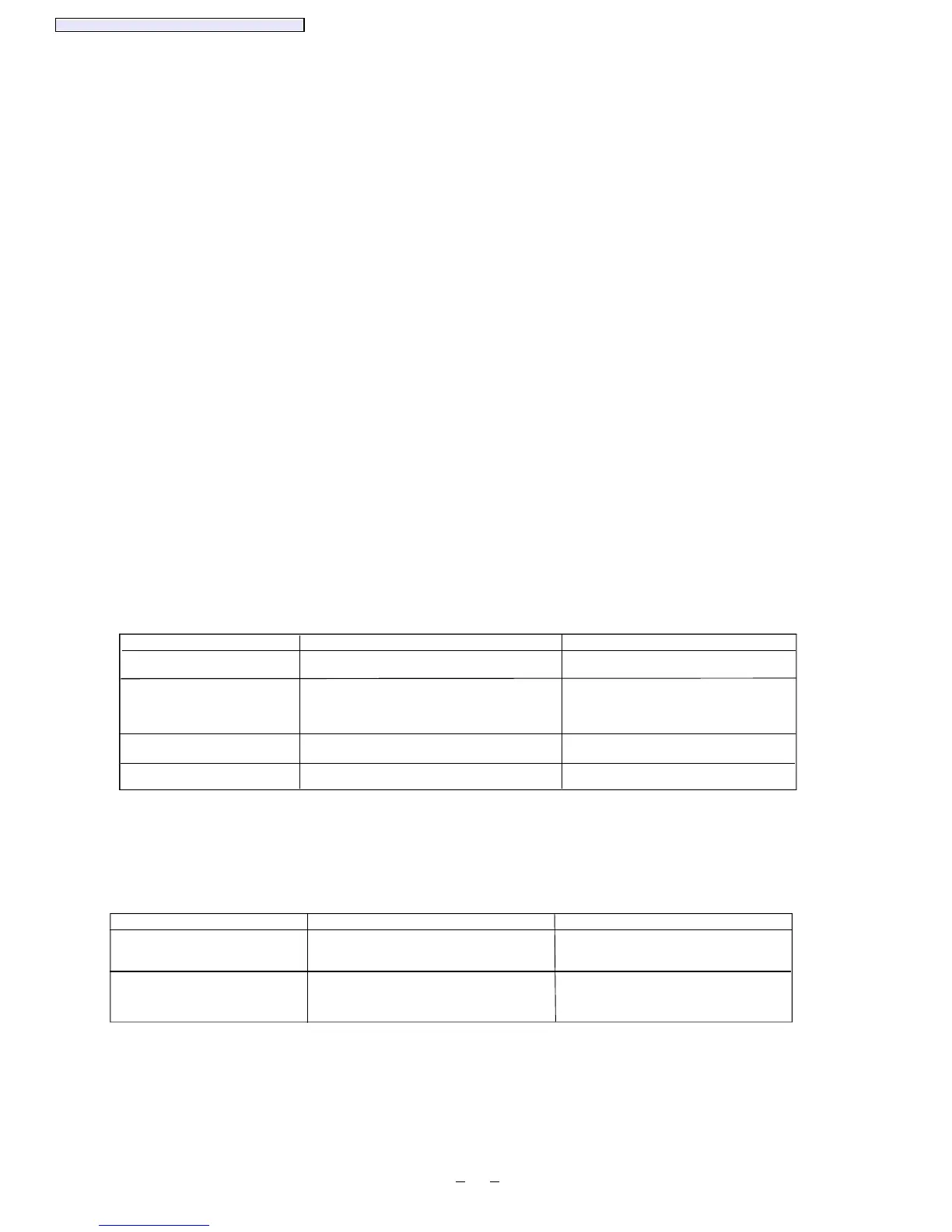

Type of work

Flar ing

Bending, connecting pipes

Air p urging

Gas leak inspection

Table 3 Tools for installation, trans ferri ng or replacement

Ordinary tools R410A tools

Fl aring t ool (cl utc h type), p ipe cut ter, re am er

To rque wrenc h (nominal diameter 1/4,

3/ 8,1 /2) Fixed s pann e r (op posing side s 12

m m , 17 m m, 19 mm ) Adj us tabl e wre nch,

Sp ring b ender

Vacuum pump H exa g onal w rench

(o pposin g sides 4 mm )

Ga s leak inspec tion fl uid or s oapy water

Cop per pip e gau ge for cleara nc e

Adju stmen t, flari ng too l (clutc h type ) *1)

Mani fold gauge, c h argin g hos e, vac uum

pump adap tor

Electric gas leak detector for HFC

refrigerant*2)

*1) Yo u can use th e conventional (R 22) flaring tool . If you ne ed t o bu y a n ew t ool, buy the R41 0A ty pe.

*2) Use when it is nec e ssary to detect smal l gas leaks.

*For o the r installa tion wor k, you sh ould have th e usual t ools , su ch as screwdrivers (+ ,-), a me tal-c utting sa w, a n

e lectrical drill, a hole core drill (65 or 70 dia .), a t ape me asu re, a l ev e l, a t her mom eter, a clamp me ter, an insulation

tester, a voltmet er, etc.

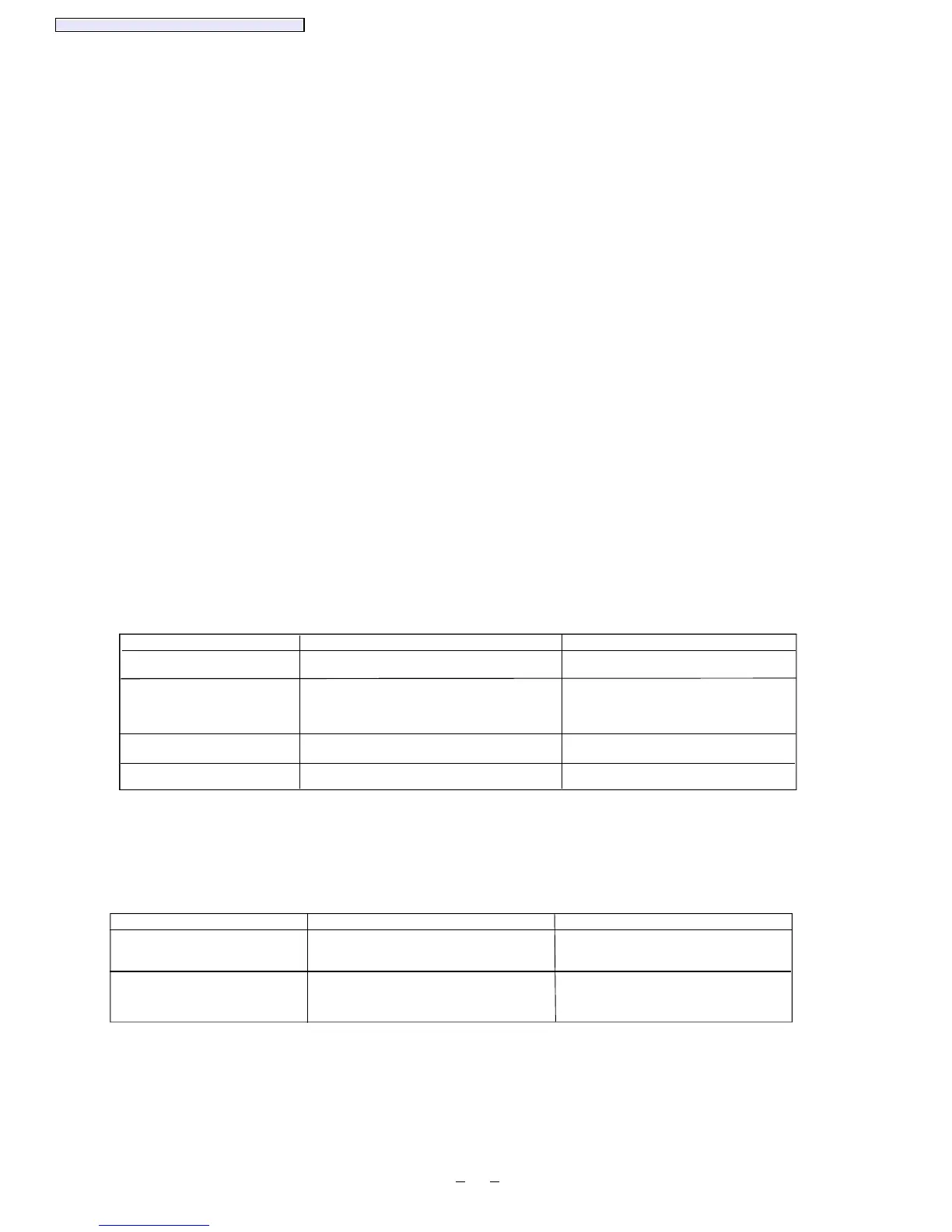

Table 4 Tool for serving

Type of work Ordinary tools

R410A tools

Refrigerant charging

Brazing (Repl acing refrigerat ing

cycle part*1)

Nitrogen blow set (be sure t o us e n itrogen

blowin g fo r all b razing ), and brazin g), an d

bra zing machine

Electro nic scale for refr iger ant c har ging

Refriger an t cyl in der Ch arg ing o rific e and

pack ing fo r refr ig erant cylinde r

*1) Always replac e the dryer o f t he out d oo r u nit at the s a me t ime. Th e replaceme nt dr yer is wrapp ed in a v a cu u m

pack. Repl ace it last among t he refriger ati n g c y c le part s. Start brazing a s soon as you ha v e o p ened t he vacuum pack,

and begin the v ac uuming

40

&6U:*.( &8U:*.( &6U:*.( &8U:*.(

&63:*.;&83:*.;&63:*.;&83:*.;

Loading...

Loading...