Thank you for purchasing this Panasonic product.

Please read these instructions carefully before attempting to install, operate or service

the Panasonic product. Please carefully read “INSTALLATION INSTRUCTIONS” (P.2~5)

of this instructions before installation. Failure to comply with instructions could result

in personal injury or property damage. Please explain to users how to operate and

maintain the product after installation, and this booklet should be presented to users.

Please carefully read “USE AND MAINTENANCE INSTRUCTIONS” (P.16~17) of this

instructions before operation.

Please retain this booklet for future reference.

Model No.

INSTALLATION AND OPERATING

INSTRUCTIONS

Energy Recovery Ventilator

FV-15ZY1

FV-50ZY1

FV-1KZY1

FV-25ZY1

FV-65ZY1

FV-1HZY1

FV-35ZY1

FV-80ZY1

FV-2KZY1

CONTENTS:

SAFETY INSTRUCTIONS

·····················

2

INSTALLATION INSTRUCTIONS

·············

2~5

INSTALLATION AND OPERATING REQUIREMENTS

·

5~6

PRODUCT FEATURES

·······················

6

SUPPLIED ACCESSORIES

····················

7

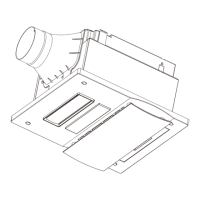

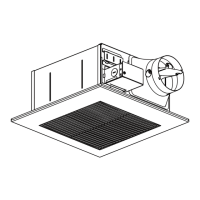

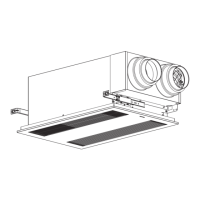

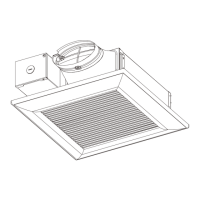

PART NAMES AND DIMENSIONS

···········

7~8

WORK BEFORE INSTALLATION

···············

9

HOW TO INSTALL

·····················

10~15

TEST RUN

···························

15~16

USE AND MAINTENANCE INSTRUCTIONS

···

16~17

MAINTENANCE

·······················

18~20

WIRING DIAGRAM

····················

21~22

TROUBLESHOOTING

······················

22

SPECIFICATIONS

··························

23

OPTIONAL ACCESSORIES

··················

24