Do you have a question about the Panasonic Intelli-Balance 100 and is the answer not in the manual?

Details airflow, static pressure, and power consumption for different models.

Details temperature, airflow, power consumption, and efficiency metrics.

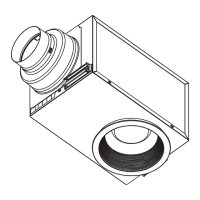

Exploded view and part numbering for the main unit assembly.

Exploded view of the frame and related components.

Exploded view of the Supply Air and Exhaust Air fan assemblies.

Exploded view of the PCB enclosure and its components.

Exploded view of the unit's outer frame cover and mounting hardware.

Lists items included in the product packaging for shipping and installation.

Step-by-step instructions for routine unit maintenance and filter replacement.

Lists part numbers, names, quantities, and remarks for main assembly components.

Lists part numbers, names, and quantities for frame components.

Lists part numbers, names, and quantities for fan assemblies.

Lists part numbers, names, quantities, and remarks for PCB enclosure components.

Lists part numbers, names, quantities, and remarks for frame cover components.

Lists part numbers and names for various unit labels.

Lists part numbers, names, quantities, and remarks for packing materials.

This document outlines the service and maintenance procedures for the Panasonic FV-10VEC2H Energy Recovery Ventilator (ERV), designed for the North American market. The ERV is a sophisticated ventilation system engineered to improve indoor air quality while minimizing energy loss. It achieves this by exchanging stale indoor air with fresh outdoor air, recovering a significant portion of the energy that would otherwise be lost through traditional ventilation methods. This process helps maintain a comfortable indoor temperature and humidity level, reducing the load on heating and cooling systems.

The FV-10VEC2H ERV operates by continuously drawing in fresh outdoor air and exhausting stale indoor air. At its core, the device features an energy recovery element, which is a heat and moisture exchange core. As the warm, humid exhaust air passes through this element, it transfers a substantial amount of its heat and moisture to the cooler, drier incoming fresh air. This pre-conditions the incoming air, making it closer in temperature and humidity to the indoor environment. This energy recovery process is crucial for reducing the energy consumption associated with conditioning outdoor air, especially in climates with significant temperature differences between indoors and outdoors.

The ERV incorporates two main fan assemblies: an Exhaust Air (EA) fan and a Supply Air (SA) fan. These fans are responsible for moving air through the system. The EA fan draws air from the indoor space, through the energy recovery core, and then exhausts it to the outside. Simultaneously, the SA fan draws fresh air from outside, through the energy recovery core, and supplies it to the indoor space. The precise control of these fans, along with integrated dampers, allows the ERV to manage airflow rates and optimize energy recovery based on various operational modes and environmental conditions.

The device is equipped with a PCB Box Assembly, which houses the main control board and various sensors. This assembly is the brain of the ERV, managing fan speeds, damper positions, and responding to input from temperature sensors and external controls like wall switches and thermostats. It also incorporates safety features and diagnostic capabilities to ensure reliable operation. The ERV can operate in different modes, including heating and cooling, to adapt to seasonal requirements. During heating, it recovers heat from the exhaust air to warm the incoming fresh air. During cooling, it transfers heat from the incoming warm air to the cooler exhaust air, while also managing moisture transfer to reduce humidity.

A key feature of the FV-10VEC2H is its ability to manage moisture transfer. In humid climates, the ERV can transfer moisture from the incoming fresh air to the drier exhaust air, helping to dehumidify the indoor space. Conversely, in dry climates, it can transfer moisture from the humid exhaust air to the drier incoming air, helping to humidify the indoor space. This balanced approach to heat and moisture exchange contributes significantly to indoor comfort and energy efficiency.

The FV-10VEC2H ERV is designed for integration into a building's HVAC system and is typically controlled via a wall switch or an external thermostat. The wall switch provides basic control functionalities, allowing users to turn the unit on or off and potentially select different operating modes or fan speeds. For more advanced control and integration with the overall HVAC system, the ERV can be connected to a furnace or an Air Handling Unit (AHU) via dedicated wiring. This allows the ERV to synchronize its operation with the building's heating and cooling cycles, ensuring optimal ventilation and energy recovery.

The device includes a "Boost Switch" option, which can be activated to provide a temporary increase in ventilation rate. This feature is useful in situations where rapid air exchange is desired, such as after cooking or when there are elevated levels of indoor pollutants. The ERV's operation is also influenced by outdoor temperature. It is designed to automatically adjust or even temporarily stop operation under extreme cold conditions (e.g., below -22 °F / -30 °C) to prevent damage and ensure efficient energy recovery, for instance, by entering a defrosting cycle to prevent the energy recovery core from freezing. This intelligent operation ensures the longevity and effectiveness of the unit.

The ERV is designed for quiet operation, minimizing noise disruption in the living space. Its components, including the fan motors and casing, are engineered to reduce vibration and sound transmission. The unit's compact design allows for flexible installation, typically in a ceiling or utility space, where it can be discreetly integrated into the building's infrastructure. The system's ability to pre-condition incoming air means that the HVAC system does not have to work as hard to maintain desired indoor temperatures, leading to reduced energy bills and a more sustainable living environment.

Regular maintenance is crucial for the optimal performance and longevity of the FV-10VEC2H ERV. The device is designed with several features to facilitate easy and safe maintenance. A key maintenance item is the air filters. The ERV includes both a Return Air (RA) filter and an Outdoor Air (OA) filter, which are essential for preventing dust, pollen, and other particulates from entering the energy recovery core and the indoor space. These filters need to be regularly inspected and cleaned or replaced to maintain good air quality and airflow. The manual provides instructions on how to access and service these filters.

The ERV is equipped with a filter indicator, typically a red LED, which illuminates to notify users when the filters require maintenance. This proactive notification system helps ensure that filter servicing is not overlooked. After servicing the filters, there is a filter reset button that needs to be pressed for 3 seconds to clear the notification. This ensures that the maintenance schedule is properly tracked.

Access to internal components for maintenance or repair is facilitated by a frame cover. The manual provides instructions on how to open and close this cover safely. It is important to ensure the frame cover is properly closed for the ERV to operate correctly. The design also considers the ease of accessing the fan assemblies and the energy recovery element for cleaning or replacement, should it be necessary.

For safety during maintenance, the manual emphasizes the importance of disconnecting power to the unit before performing any service. This is a critical safety precaution to prevent electrical shock. The device also incorporates a main switch within the product body, which should be checked during troubleshooting to ensure it is in the "on" position.

Troubleshooting guidance is provided to help identify and resolve common issues. The running indicator (green LED) and filter indicator (red LED) provide visual cues for diagnosing problems. For instance, different blink patterns of the running indicator can signal specific errors such as SA motor error, EA motor error, damper errors, or sensor malfunctions. In such cases, the recommended action is often to disconnect power and contact a professional technician. The manual also highlights the importance of checking wiring connections, especially for the HVAC/AHU interface, if the ERV is not working as expected with the building's main system.

The design of the ERV also includes components like the PCB Box Assembly, which can be accessed for servicing the main control board. However, it is strongly advised that only experienced repair technicians handle these internal components, especially those marked with a triangle in the diagrams, as they are critical for safety and proper operation. The manual also suggests handling parts with static electricity prevention measures and avoiding touching PCB parts with bare hands during repairs to prevent damage. This comprehensive approach to maintenance ensures the ERV remains a reliable and efficient component of a building's ventilation system.

| Model | FV-10VEC1 |

|---|---|

| Brand | Panasonic |

| Type | Energy Recovery Ventilator |

| Duct Diameter (inches) | 6 |

| ENERGY STAR Certified | Yes |

| Installation | Ceiling |

| Motor Type | DC Motor |

| Speed Settings | 3 |

| Remote Control | No |

| Timer | No |

| Reverse Function | No |

| Airflow at 0.1 in. wg (CFM) | 100 |

| Sound Level (sones) | 0.3 - 0.8 |

| Air Delivery | 100 CFM |

| Noise Level | 0.3 sones |

Loading...

Loading...