3 - 8

2WAY SYSTEM

Outdoor Unit Repair Procedures

3

4. Recovering Refrigerant

The following equipment and tools are required:

Jumper wire with clips, adjustable wrench, set of manifold gauge valves specially designed for refrigerant R410A

only, vacuum pump, refrigerant recovery unit, pre-purged refrigerant cylinder for recovery, flathead screwdriver, and

outdoor unit maintenance remote controller.

4-1. Refrigerant Recovery Procedures (from outdoor unit)

(1) Turn off the power of the outdoor unit beforehand (at power mains).

(2) Fully close each service valve on the liquid tube, gas tubes, and the balance tube of the outdoor unit.

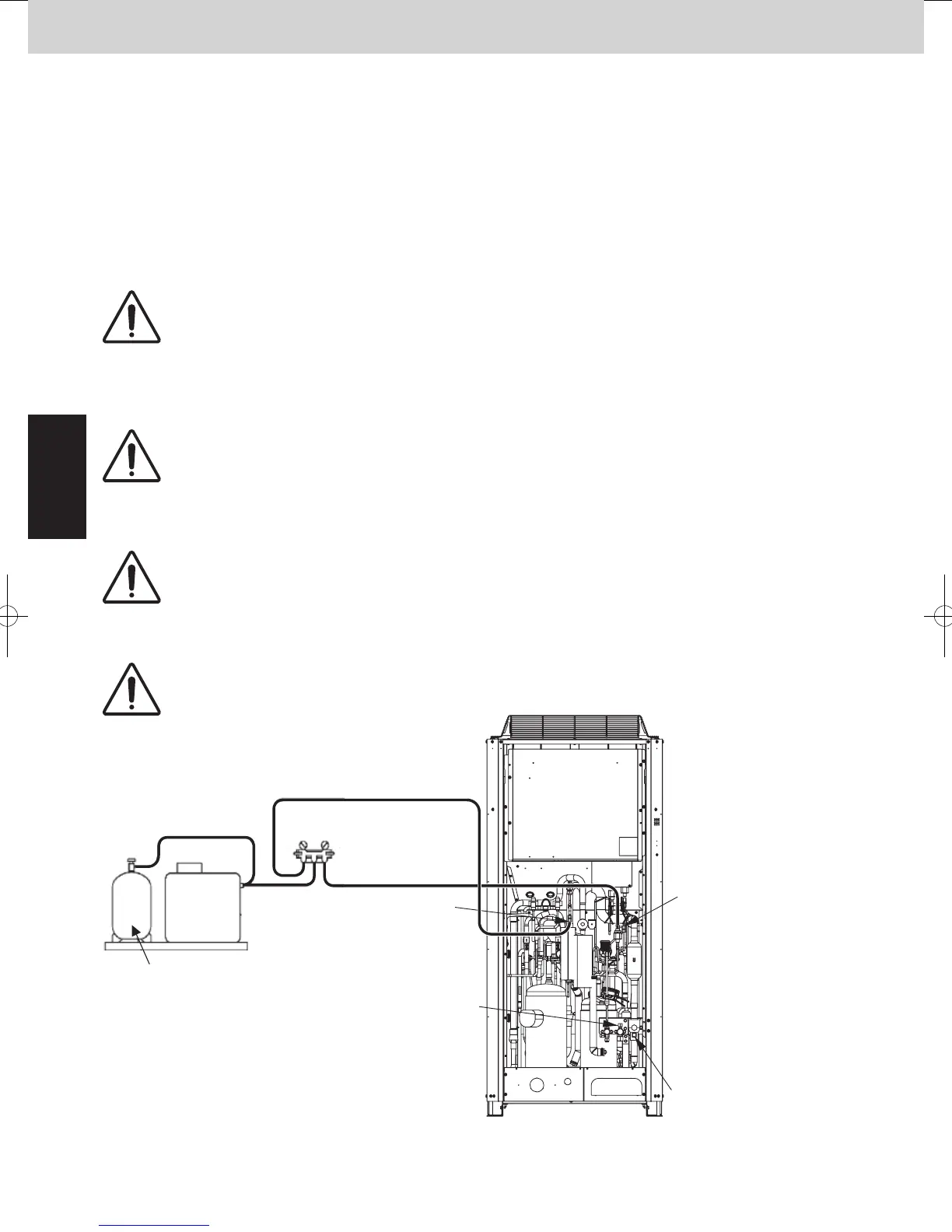

(3) Connect the outdoor unit’s high-pressure and low-pressure outlet ports with the Hi and Lo sides of the mani-

fold gauge valves using hoses. (Fig. 3)

The remaining refrigerant in the faulty outdoor unit may create internal pressure.

Before connecting hoses, be sure to confirm that each of the manifold gauge

valves is tightly closed. Note that the connection ports employ Schrader-type

push-to-release valves.

CAUTION

(4) Connect the manifold gauge valves, refrigerant recovery unit, and recovery cylinder using hoses. To avoid the

entry of air into the refrigerant tubing, carry out this connection work carefully. (Fig. 3)

For detailed procedures such as connecting the refrigerant recovery unit with the

recovery cylinder and methods used for recovery, follow the specific instructions

that came with the refrigerant recovery unit.

CAUTION

(5) Locate the AP (Air Purge) pins on the control PCB in the faulty outdoor unit and short them using the clips of

the jumper wire. Then restore electrical power to the outdoor unit.

By short-circuiting the AP pins, each solenoid valve in the outdoor unit is forcibly

opened as soon as power comes on, which releases all remaining refrigerant into

the recovery cylinder. Since neglecting this procedure may leave some refrigerant

in the system, it is important that you carry out this step.

CAUTION

(6) Carry out refrigerant recovery.

To determine the completion of refrigerant recovery, follow the instructions that

came with the refrigerant recovery unit.

CAUTION

High-pressure outlet port

(for ø7.94mm-dia connector)

Liquid tube service port

(for ø7.94mm-dia connector)

Gas tube service port

(for ø7.94mm-dia connector)

Type 8HP / 10HP / 12HP

Refrigerant recovery cylinder

Refrigerant

recovery unit

Manifold

gauge

Lo Hi

Low-pressure outlet port

(for ø7.94mm-dia connector)

Fig. 3-a

SM830204-05_2WAY SYS_new.indb 8 15/01/05 15:31:29

Loading...

Loading...