Slide # 16

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

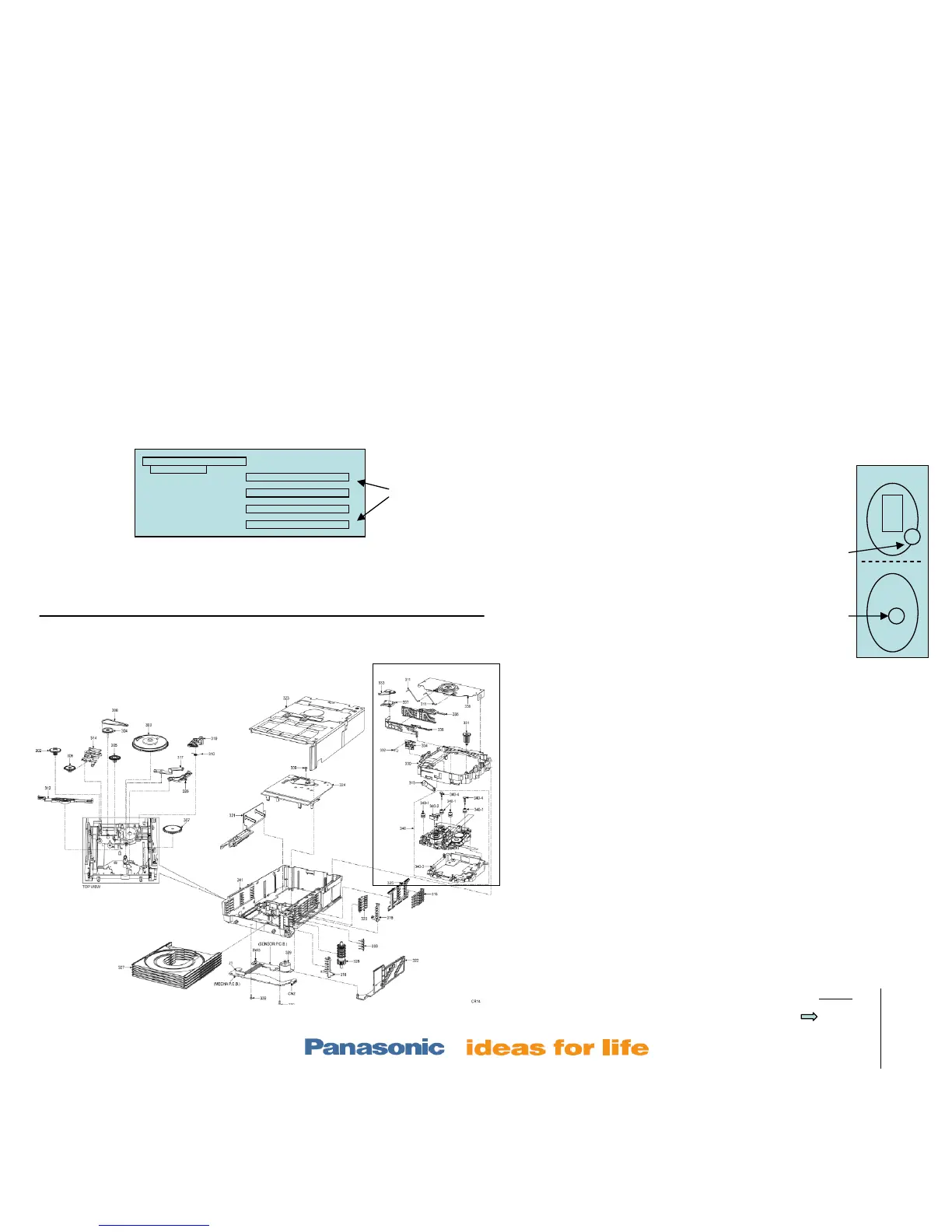

5 Disc Mechanism - Concept & Transfer Alignment 1/4

Figure 1b – mech components

Operational Concept:

There are 2 motors and 8 sensors in the CR-14 mech.

I. The traverse motor moves:

• Laser back & forth

• Clamps disc

• Pulls trays into the laser assembly

II. The stocker motor moves

• Tray(s) between the middle stocker

area and out of the assembly

(for disc insertion)

• Traverse / laser platform up/dwn,

III. Trays moved from the stock area must be

transferred to the laser area.

1) Tray transfer is made after the traverse assembly

elevators to the desired tray level. The following

occurs in the rear traverse assembly:

2) The traverse motor uses arms to pull the tray into

gear #331. Pictures in the fourth slide 4/4.

3) SW4 opens (fp 8251) to tell the micro the tray is in.

4) The traverse motor continues to turn, bringing the tray

in, then clamps the disc

5) SW5 opens (fp 8251) at clamp end and sled moves

away from home.

6) The sled moves the laser to the approx TOC disc

area & stops. The laser comes on, lens focus

searches and if a disc is found, spins it.

7) SW4 and SW5 are both inside the Traverse

assembly.

laser

Stock

area

Trays 2-5rear

Figure 1a – Default position

side view

rear

Traverse

assembly p/n =

RD-DDtx002-V

Mech

p/n = RD-ddc 026-S

laser

Tray 1

Stock

motor

traverse

motor

Top

view

Loading...

Loading...