5

5 - 15

3WAY SYSTEM

Trouble Diagnosis

4. 3WAY Alarm Codes

F17 Alarm

Alarm code F17

Alarm meaning Low-pressure sensor trouble

Alarm conditions

(2) Sensor open circuit

Probable cause

(2) PCB malfunction

Check

(1) Sensor short circuit

(1) Sensor malfunction (including connector)

(1) Measure the sensor resistance. Check that the sensor is operating normally.

(2) Use a remote monitor or a PC monitor to check the temperature that is recognized

by the microcomputer.

F31 Alarm

Alarm code F31

Alarm meaning Outdoor unit non-volatile memory (EEPROM) trouble

Alarm conditions

(2) Read values do not match after writing to non-volatile memory is complete.

Probable cause

(1) Non-volatile memory is not present when power initialization occurs.

(1) Memory was not inserted after the PCB was replaced.

(2) The lifetime of the non-volatile memory has been reached.

(3) Non-volatile memory is installed incorrectly (wrong direction, bent pins, etc.).

Check (1) Check the non-volatile memory on the PCB.

Correction

Example

Notes

—

Correction —

—

Example —

—

Notes —

(1) Wiring failure

(2) Operating under extremely high-pressure status (over-loaded operation)

(3) Power source and voltage failure (sudden voltage decrease)

(2) Operating under extremely high-pressure status

(over-loaded operation)

Check open/closed status of the service valve of the outdoor unit.

(3) Check power source and voltage.

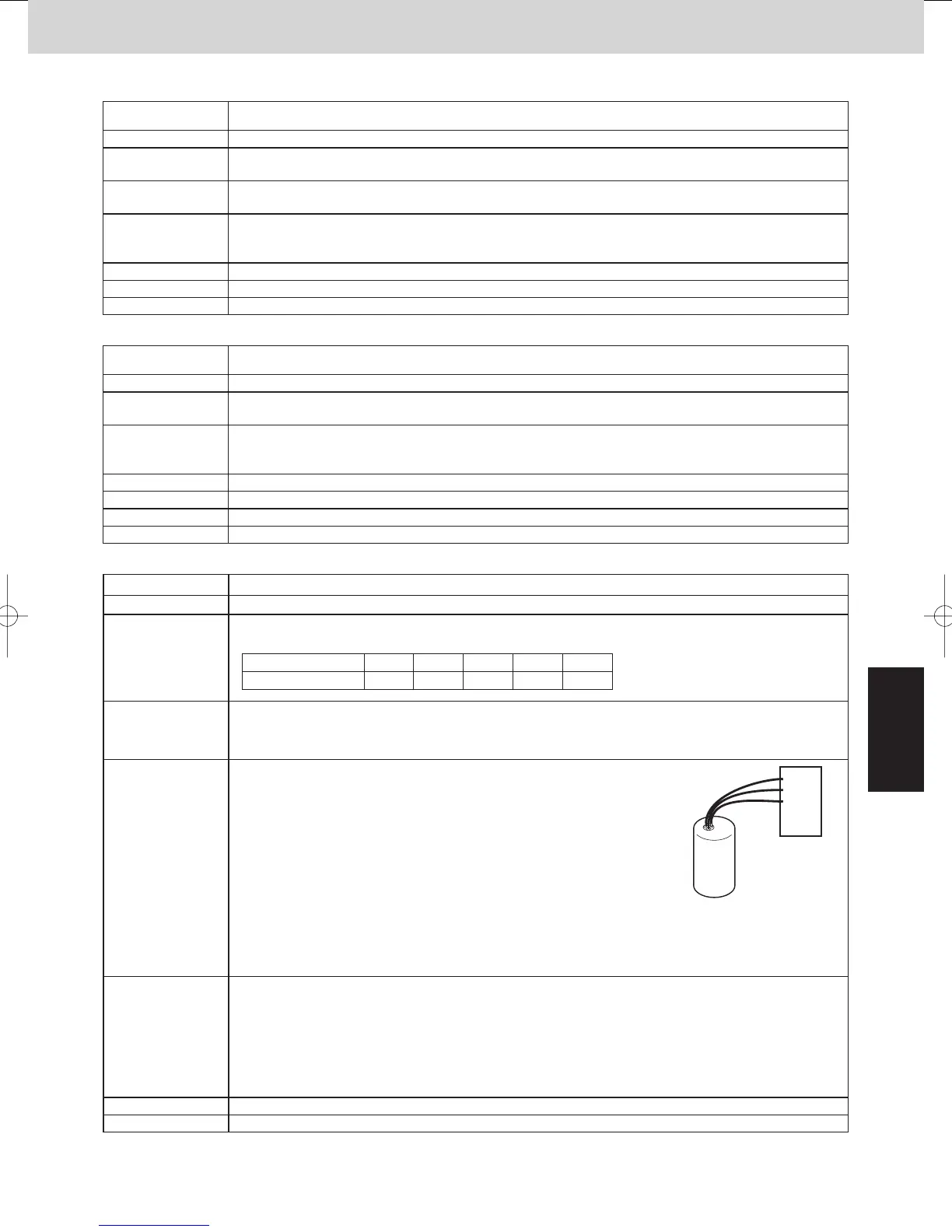

H01 Alarm

Alarm code

Alarm meaning

Alarm conditions

Probable cause

Check

Correction

Example

Notes

H01

Compressor 1Currenttrouble

Compresor 1 (INV) primary current detected overcurrent higher than the values (overcurrent) listed

in the table below.

(1) Wiring failure

(2) Operating under extremely high-pressure status (over-loaded operation)

(3) Improving power source and voltage

(1) Wiring failure

—

—

Horsepower of unit

Current (A)

8HP

15.1

10HP

19.8

12HP

21.0

14HP

21.0

16HP

22.5

Failure to open the service valve of the outdoor unit•

Check whether the connection between "HIC PCB" and " inverter

compressor" is wiring failure.

See the fugure at right.

Difference of characteristics of high-pressure sensor (under-shift)•

Open the service valve of the outdoor unit.•

Correct wiring disconnection and wiring failure.

Replacing high-pressure sensor

When replacing a high-pressure sensor, carry out after refrigerant recovering of the outdoor unit.

•

Connect a gauge to the high-pressure outlet and check for

changes in the value dispalyed by the monitoring software, and for

large deviation of the gauge pressure.

•

Inverter compressor

HIC PCB

U

V

W

5/A9#;'%1K5;56'/A5G

Loading...

Loading...