43

© Copyright 2008 Panoramic Corporation

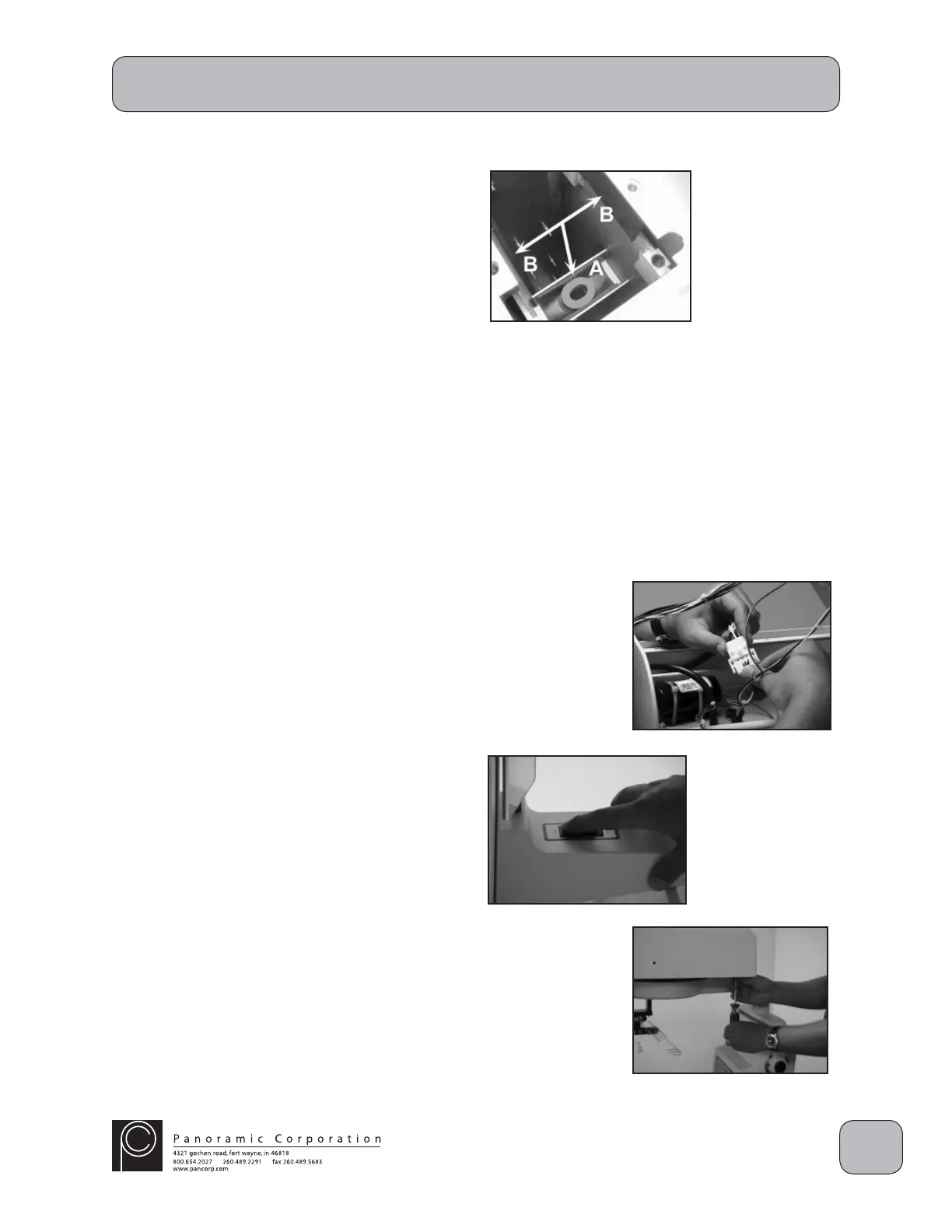

10. Install new rubber gaskets included with the

screw motor.

A. The bracket mounted in the column will

receive two gaskets: fi rst insert the black

gasket with the hole. Center the hole with

the hole on the bracket. Run a fi nger along

the bottom side of the bracket making sure

the gasket is centered. Next insert the

orange "donut" on top of the black gasket

again; make sure all holes are lined up.

B. Remove the protective backing from the

self-adhesive gasket. The two rubber pads

will be installed in the inner column on the

mounting block for the screw motor plate.

11. Lower the replacement screw motor assembly

into the column, ensuring that the threaded

screw shaft is inserted through the bracket on

the inner column.

12. Now install the 2 5/16" allen head bolts that

are shipped with the replacement screw

motor and install them in opposite corners of

the mounting plate. Tighten these two bolts

down, drawing the mounting plate closer to the

overhead of the machine. Now you can install

two of the original 5/16" bolts in the remaining

open mounting holes and tighten them

completely. Last, remove the 2 5/16" allen

head bolts that came with the replacement

motor and reinstall the last two original bolts.

13. Reconnect the molex connector J11/P11.

14. Hinge the aluminum chassis back down into

position, but do not reinstall the mounting

screws, yet.

15. Power the PC-1000 on and verify that the new

screw motor assembly is working properly.

16. Reinstall the 4 screws on the aluminum

chassis in the overhead.

17. Slide the top cover on the machine from the

front and reinstall the 6 screws. Ensure that

the wiring on the control panel side is properly

routed.

Screw Motor Assembly Exchange

S0105

S0107

Loading...

Loading...