7

Step 5 — Refrigerant Tubing Connection and

Evacuation

Use accessory tubing package or field−supplied tubing of

refrigerant grade. Suction tube must be insulated. Do not use

damaged, dirty, or contaminated tubing because it may plug

refrigerant flow−control device. ALWAYS evacuate the coil and

field−supplied tubing to 500 microns before opening outdoor unit

service valves.

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product or property

damage.

A brazing shield MUST be used when tubing sets are being

brazed to the unit connections to prevent damage to the unit

surface and condensate pan fitting caps.

CAUTION

!

Units have sweat suction and liquid tube connections. Make

suction tube connection first.

1. Cut tubing to correct length.

2. Insert tube into sweat connection on unit until it bottoms.

3. Braze connection using silver bearing or non−silver bearing

brazing materials. Do not use solder (materials which melt

below 800F / 427C). Consult local code requirements.

4. Evacuate coil and tubing system to 500 microns using deep

vacuum method.

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product or property

damage.

Wrap a wet cloth around rear of fitting to prevent damage to

TXV and factory−made joints.

CAUTION

!

Step 6 — Refrigerant Flow−Control Device

The PF4MNB fan coil is equipped with R−410A refrigerant TXV.

Use outdoor units designed for R−410A refrigerant only.

PRODUCT OPERATION HAZARD

Failure to follow this caution may result in improper product

operation.

If using a TXV in conjunction with a single−phase

reciprocating compressor, a compressor start capacitor and

relay are required. Consult outdoor unit pre−sale literature for

start assist kit part number.

CAUTION

!

Step 7 — Condensate Drains

To connect drains, the cap openings must be removed. Use a knife

to start the opening near the tab and using pliers, pull the tab to

remove the disk. Clean the edge of the opening if necessary and

install the condensate line. Finally caulk around the lines where

they exit the fitting to retain the low leak rating of the unit.

UNIT OR PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in product or

property damage.

The conversion of the fan coil to downflow requires special

procedures for the condensate drains on both A−coil and

slope units. The vertical drains have an overflow hole

between the primary and secondary drain holes. This hole is

plugged for all applications except downflow, but must be

used for downflow. During the conversion process, remove

the plastic cap covering the vertical drains only and discard.

Remove the plug from the overflow hole and discard. At

completion of the downflow installation, caulk around the

vertical pan fitting to door joint to retain the low air leak

performance of the unit.

CAUTION

!

Units are equipped with primary and secondary 3/4−in. FPT drain

connections. For proper condensate line installations see Fig. 1, 2,

3, 5 and 6. To prevent property damage and achieve optimum

drainage performance, BOTH primary and secondary drain lines

should be installed and include properly−sized condensate traps.

(See Fig. 15 and 16.) Factory−approved condensate traps are

available. It is recommended that PVC fittings be used on the

plastic condensate pan. Finger−tighten plus 1−1/2 turns. Do not

over−tighten. Use pipe dope.

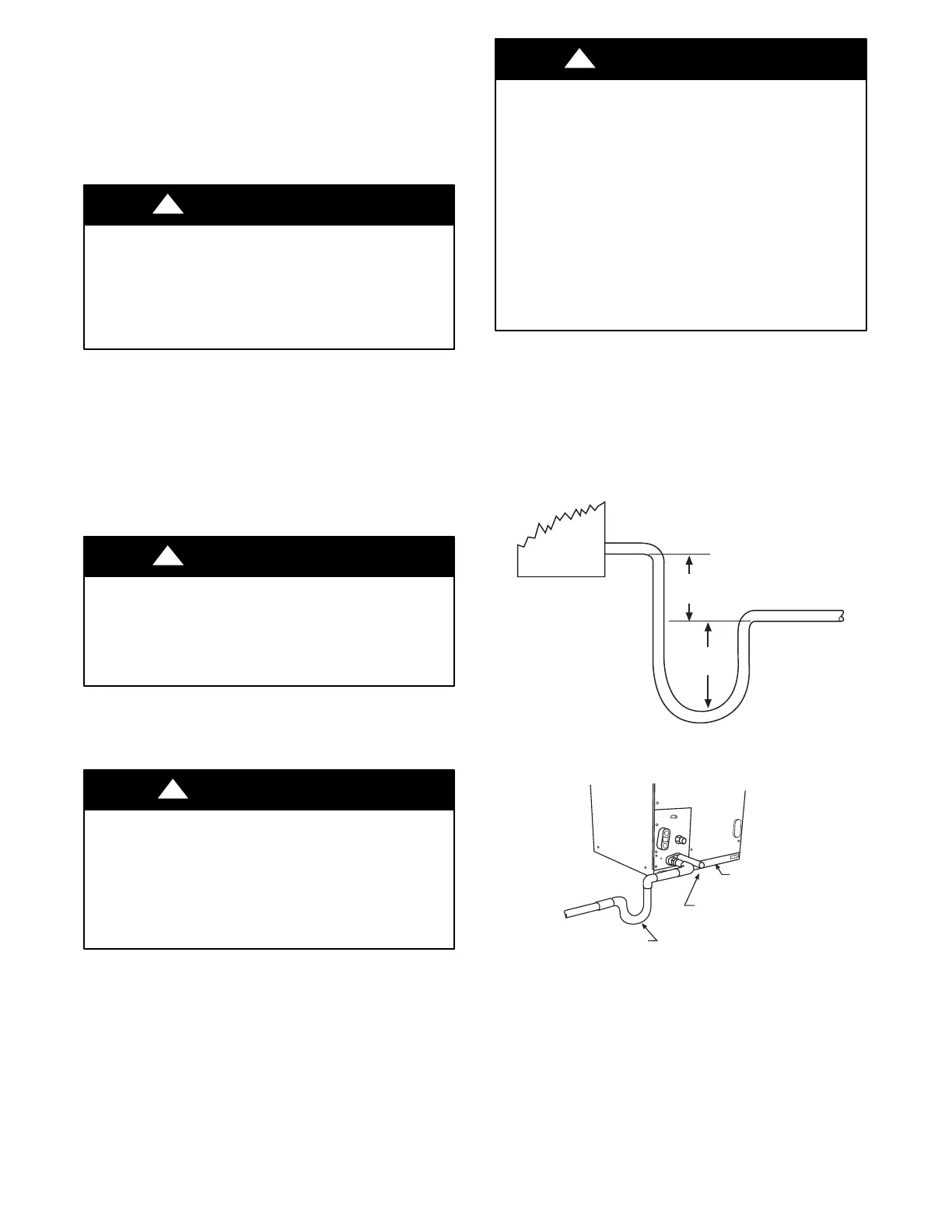

2” MIN

(51 mm)

UNIT

2” MIN

(51 mm)

A03002

Fig. 15 − Recommended Condensate Trap

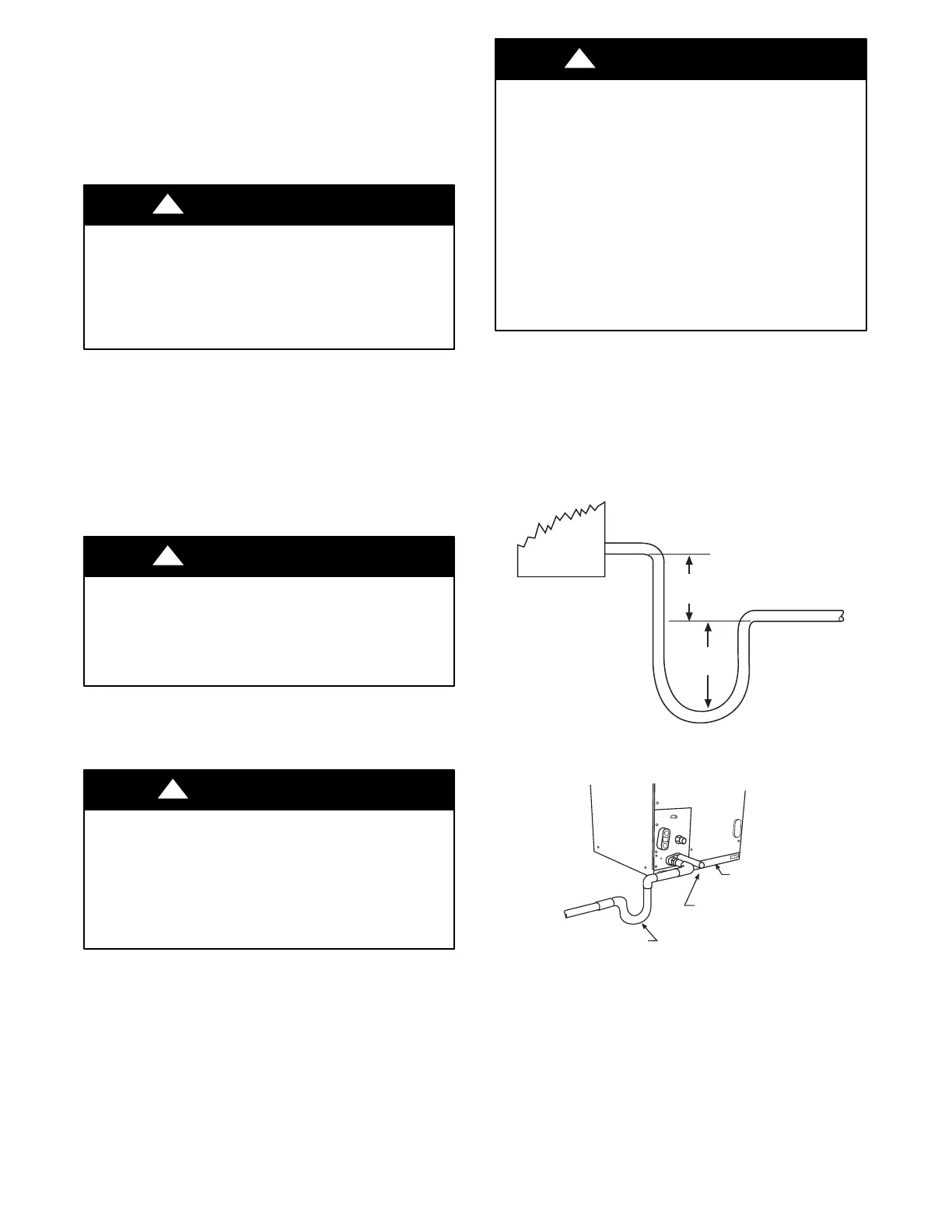

FILTER

ACCESS

PANEL

SECONDARY DRAIN WITH

APPROPRIATE TRAP REQUIRED

(USE FACTORY KIT OR

FIELD-SUPPLIED TRAP)

PRIMARY TRAP REQUIRED

(USE FACTORY KIT OR

FIELD-SUPPLIED TRAP OF

SUFFICIENT DEPTH.

STANDARD P-TRAPS ARE

NOT SUFFICIENT. SEE

FIGURE OF RECOMMENDED

CONDENSATE TRAP)

A03003

Fig. 16 − Condensate Trap and Unit

Loading...

Loading...