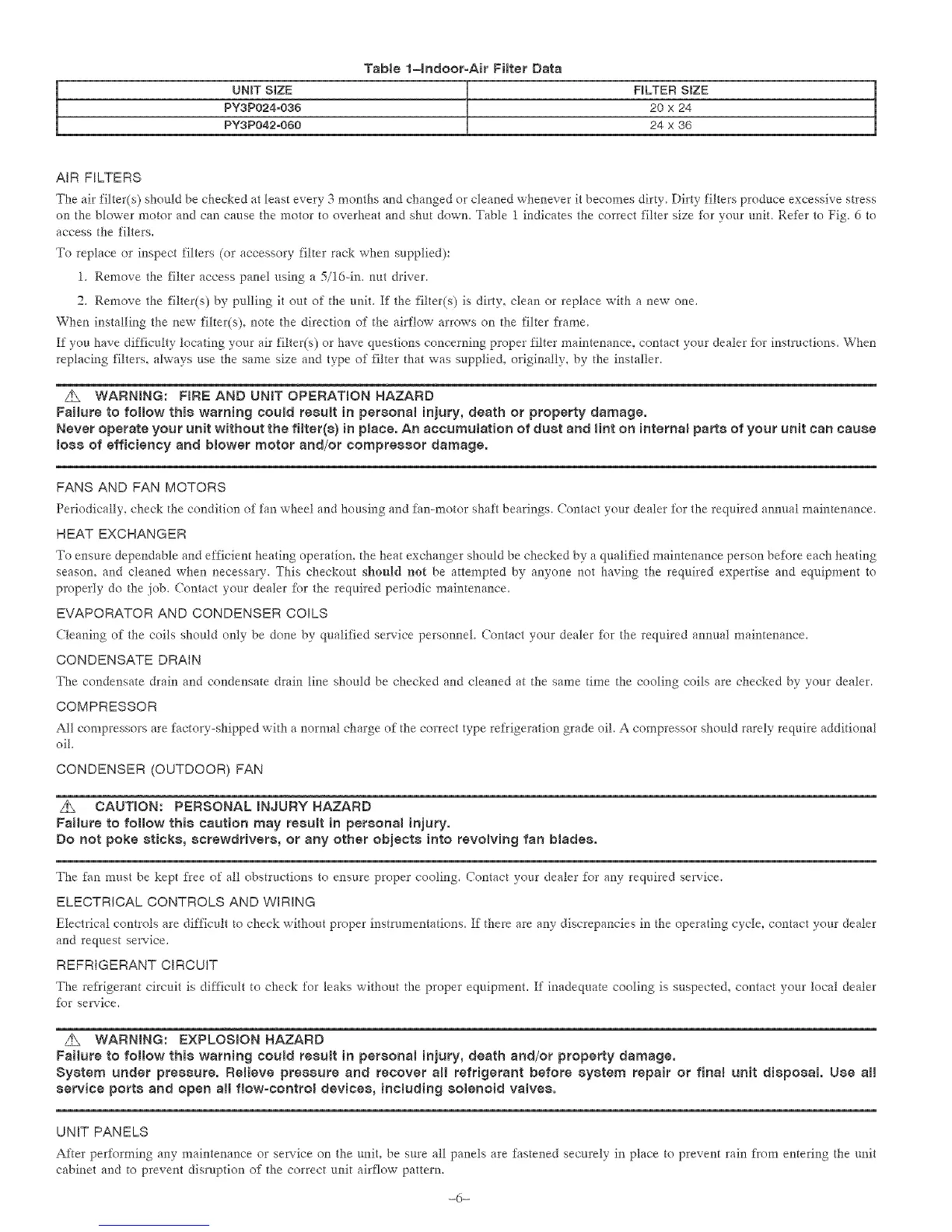

UNiT S_ZE

PY3P024-036

PY3P042-060

Table 1Mndoor=Air FiRer Data

F_LTER S_ZE

20 x 24

24 x 36

1

AiR FILTERS

The air filter(s) should be checked at least every 3 months and changed or cleaned whenever it becomes dirty, r)irty filters produce excessive stress

on the blower motor and can cause the motor to overheat and shut down. Table 1 indicates the correct filter size for your unit. Refer to Fig. 6 to

access the filters.

To replace or inspect filters (or accessory filter rack when supplied):

1. Remove the filter access panel using a 5/16-in. nut driver.

2. Remove the filter(s) by pulling it out of the unit. If the filter(s) is dirty, clean or replace with a new one.

When installing the new tilter(s), note the direction of the airflow arrows on the tilter frame.

If you have difficulty locating your air filter(s) or have questions concerning proper filter maintenance, contact your dealer _br instructions. When

replacing filters, always use the same size and type of filter that was supplied, originally, by the installer.

WARNING: FIRE AND UNIT OPERATION HAZARD

Failure to follow this warning could resuR in personat injury, death or property damage.

Never operate your unit without the filter(s} in place. An accumulation of dust and Hnt on internal parts of your unit can cause

loss of efficiency and blower motor and/or compressor damage.

FANS AND FAN MOTORS

Periodically, check the condition of fan wheel and housing and fan-motor shaft bearings. Contact your dealer for the required ammal maintenance.

HEAT EXCHANGER

To ensure dependable and efficient heating operation, the heat exchanger should be checked by a qualified maintenance person be_bre each heating

season, and cleaned when necessary. This checkout should not be attempted by anyone not having the required expertise and equipment to

properly do the job. Contact your dealer %r the required periodic maintenance.

EVAPORATOR AND CONDENSER COILS

(leaning of the coils should only be done by qualified service personnel. Contact your dealer for tile required annual maintenance.

CONDENSATE DRAIN

The condensate drain and condensate drain line should he checked and cleaned at the same time the cooling coils are checked by your dealer.

COMPRESSOR

AII compressors are factory-shipped with a normal charge of the correct type refrigeration grade oil. A compressor should rarely require additional

oil.

CONDENSER (OUTDOOR) FAN

Z_ CAUTUON: PERSONAL iNJURY HAZARD

Failure to follow this caution may resuR in personal injury.

Do not poke sticks, screwdrivers, or any other objects into revolving fan Nades.

The fan must be kept 5"ee of all obstructions to ensure proper cooling. Contact your dealer _br any required service.

ELECTRICAL CONTROLS AND WIRING

Electrical controls are difficult to check without proper instrumentations. If there are any discrepancies in tile operating cycle, contact your dealer

and request service.

REFRIGERANT CIRCUIT

The refi'igerant circuit is difficult to check for leaks without the proper equipment. If inadequate cooling is suspected, contact your local dealer

_br service.

Z_ WARNING: EXPLOSUON HAZARD

Failure to follow this warning could resuR in personal injury, death and/or property damage.

System under pressure. Regeve pressure and recover aH refrigerant before system repair or finaJ unit disposal Use aH

service ports and open aH flow-control devices, incJuding solenoid valves.

UNIT PANELS

After perfoiming any maintenance or service on the unit, be sure all panels are fastened securely in place to prevent rain from entering the unit

cabinet and to prevent disruption of the correct unit airflow pattern.

Loading...

Loading...