ASAHI/AMERICA, INC 655 ANDOVER STREET LAWRENCE, MA. 01843 TELEPHONE 800-343-3618

Location: assembly/manuals Series 92 A/C Modulating Svc Manual Gen II Rev. A 11/15/19

Page 5 of 26

Installation

Electrical

Reference Drawing #289S92

Models S-92, A92, & B92

1A. To gain access to terminal strip (Part #24) it is necessary to remove manual

override knob (Part #18) by loosening slotted setscrew (Part #39). Remove 2

cover screws and cover; the remaining 6 cover screws are packaged inside

the actuator.

Model C92

1B. To gain access to terminal strip it is necessary to remove manual override

hand wheel (Part #18A) by loosening slotted setscrew (Part #39). Remove

cam (Part #51) by loosening 2 set screws (Part #52). Remove 2 cover screws

and cover; the remaining 6 cover screws are packaged inside the actuator.

All Models

2. Make electrical connections to terminal strip as shown on wiring schematic

located inside the cover (per various electrical codes there is a green screw

on the actuator base plate for grounding purposes). All units are completely

calibrated prior to shipment, and no internal adjustments should be required.

3. Install 1/2" NPT conduit fitting(s) to actuator base. Please ensure that proper

conduit fitting is used to maintain enclosure rating (weatherproof, explosion proof

or combination weather proof/explosion proof).

NOTE: We recommend sealing conduit openings on units installed outdoors or

exposed to large temperature swings (15ºF or more).

We also recommend the heater and thermostat option in these applications.

4. Replace actuator (gasket if removed) cover, and install 8 cap screws supplied

and tighten securely. For outdoor or wet locations it is recommended prior to

replacing the cover that the top shaft seal be cleaned and coated with silicone

grease. Also clean shaft and lightly coat seal area of shaft with silicone

grease. Unit is now ready for operation.

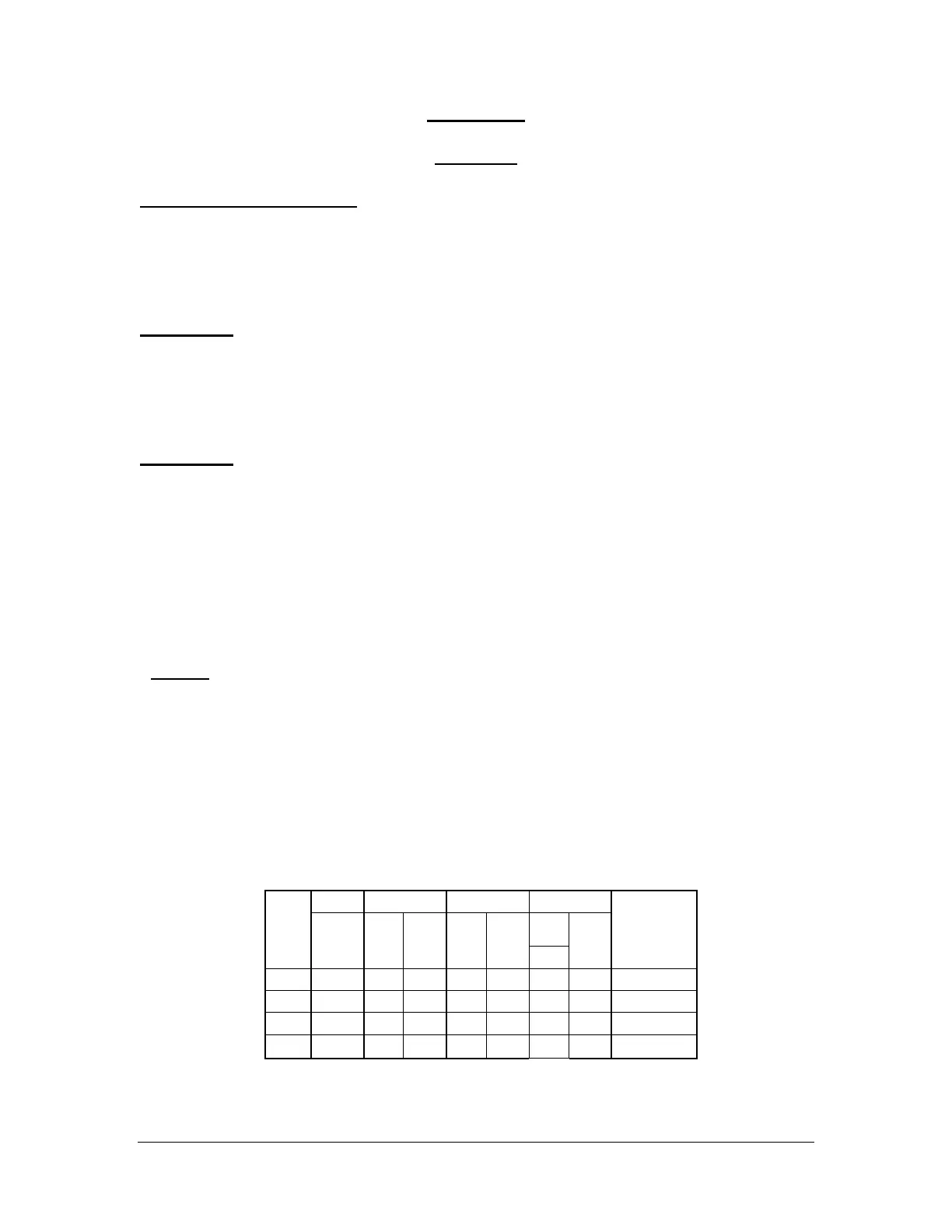

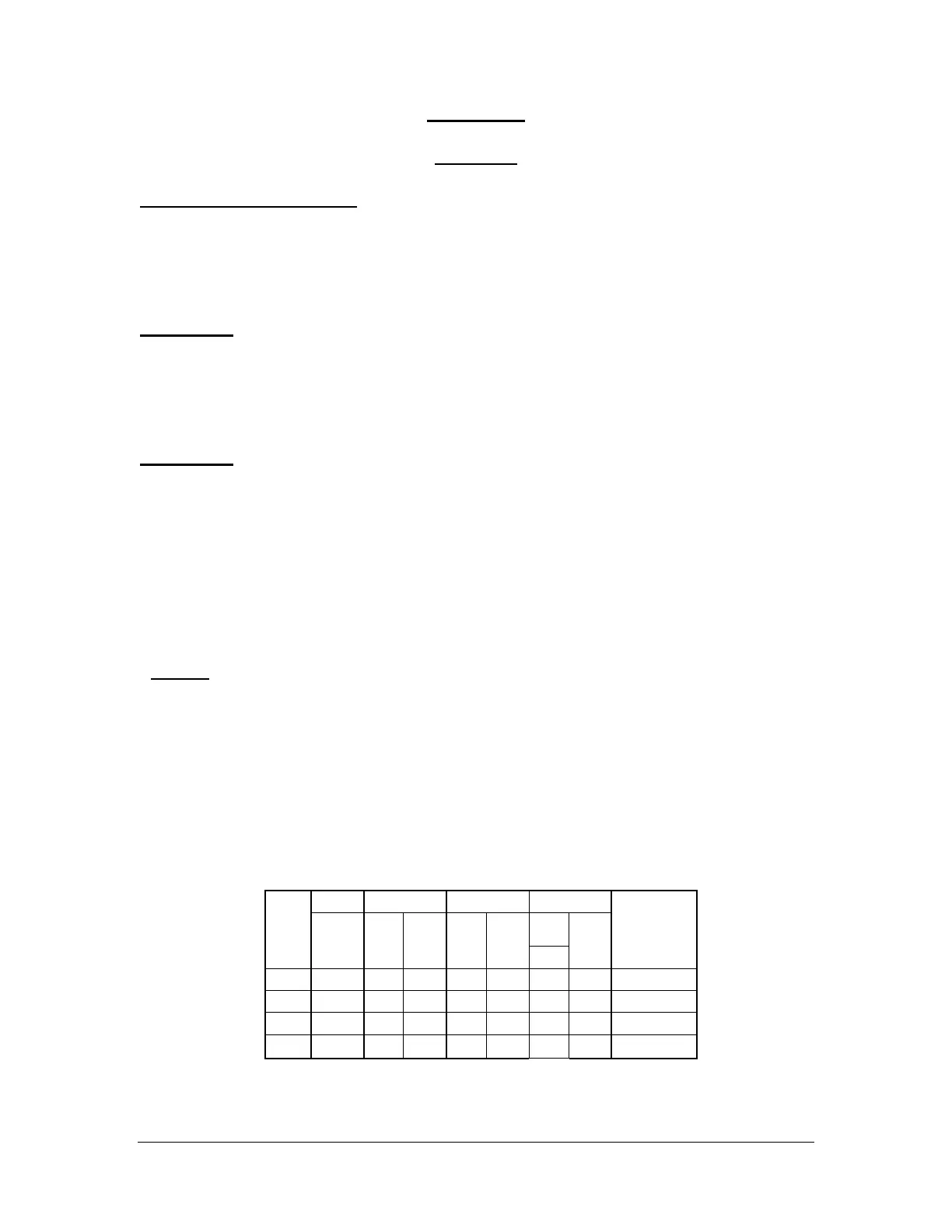

Cycle Time

per 90

Degrees

NOTE: Amp rating is considered locked rotor.

Duty cycles are for ambient tempe

rature (73°F)

Loading...

Loading...