The Company

Since its organization in 1886, the Penberthy Manu-

facturing Co.* has been well known as a leading

manufacturer of injectors. As a result of its superior

basic injector design, continued improvements in

performance, manufacturing methods and standard

of quality, Penberthy leadership in the injector field

has been universally recognized for many years.

Penberthy injectors and service parts may be

purchased from any one of the thousands of jobber

and dealer representatives in all principal cities and

countries of the world. Their knowledge of the vari-

ous applications of the Penberthy injector, covering

many years of experience, assures prospective users

that they will obtain intelligent engineering sales

service.

Automatic Restarting

All Penberthy injectors are of the automatic restarting type.

If the established flow of water from an injector to the boiler

is interrupted temporarily by t he admission of air into the

suction line or by a jolt causing the overflow valve to open,

the injector will automatically reestablish flow without the

necessity of regulating any valves.

Feeds Warm Water to Boiler

Penberthy injectors feed water into the boiler at a tempera-

ture of from 130°F to 212°F depending upon the steam pres-

sure and t emperature of the supply water. By throttling the

water supply line, feed water temperatures up to 212°F can

be obtained under most conditions of operation.

Design

Injectors are designed so as to give well-balanced operation

against the greatest possible range of steam pressure, water

tem

erature and suction lift and to maintain satisfactor

PENBERTHY AUTOMATIC INJECTORS

performance for a long period of service. Designs are t he

result of years of experience with injector applications.

Injector connections have uni on tailpipes permitting quick

removal from the line.

all parts are easily removed for cleaning or replacement and

are precision made to assure interchangeability in the field.

Workmanship is highest quality. Years of manufacturing has

resulted in the training of skilled craftsmen and the develop-

ment of advanced production methods.

Material

Injectors are of all bronze construction with special bronze

alloys being used for suction and delivery jets to resist wear.

Inspection and Testing

All injectors are tested at the factory on actual boiler installa-

tions, assuring that injectors will meet all performance claims

as specified for the various models.

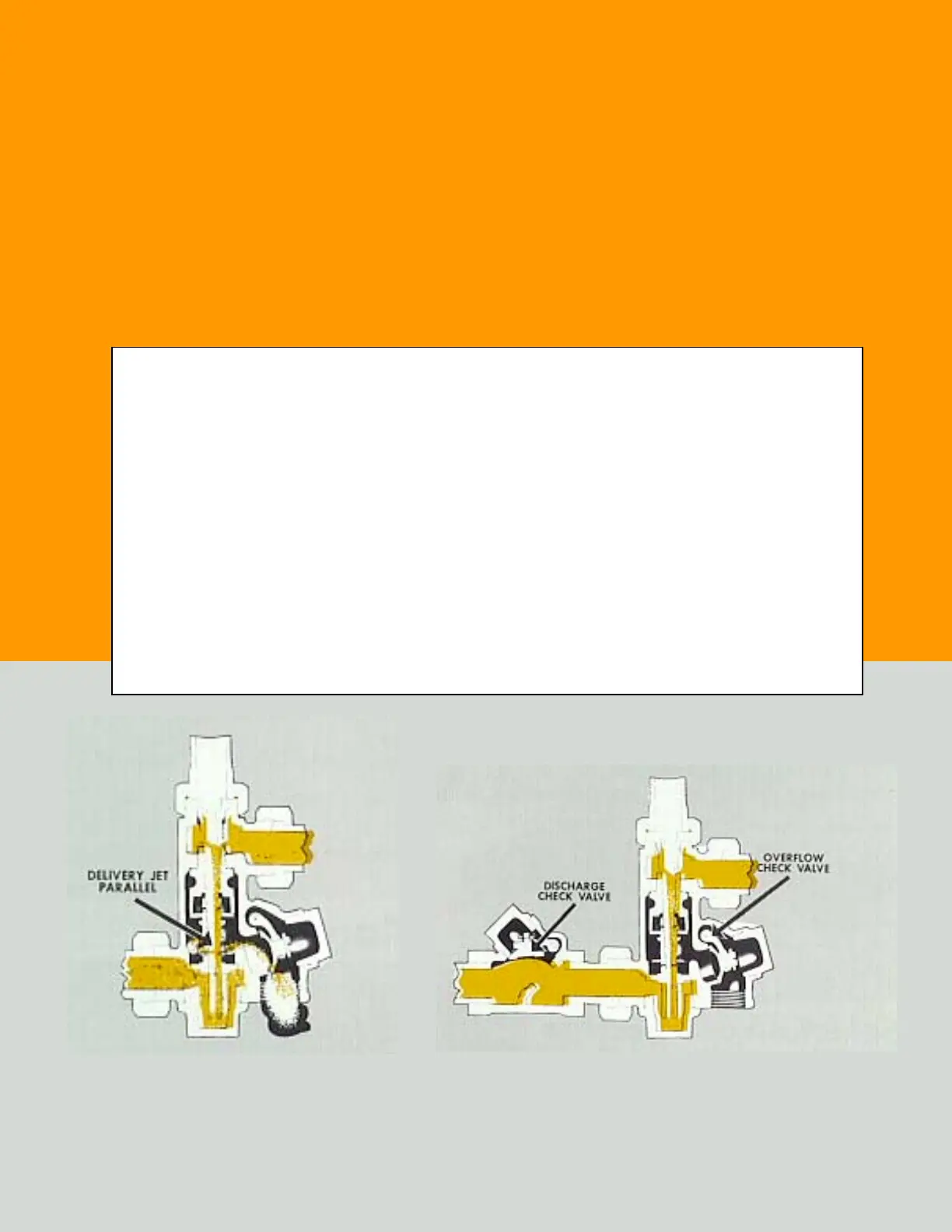

When the amount of steam and water reach the proper

proportion, the steam gradually condenses as the mix-

ture advances through injector. Upon reaching deliver

et

arallel the mixture is full

condensed.

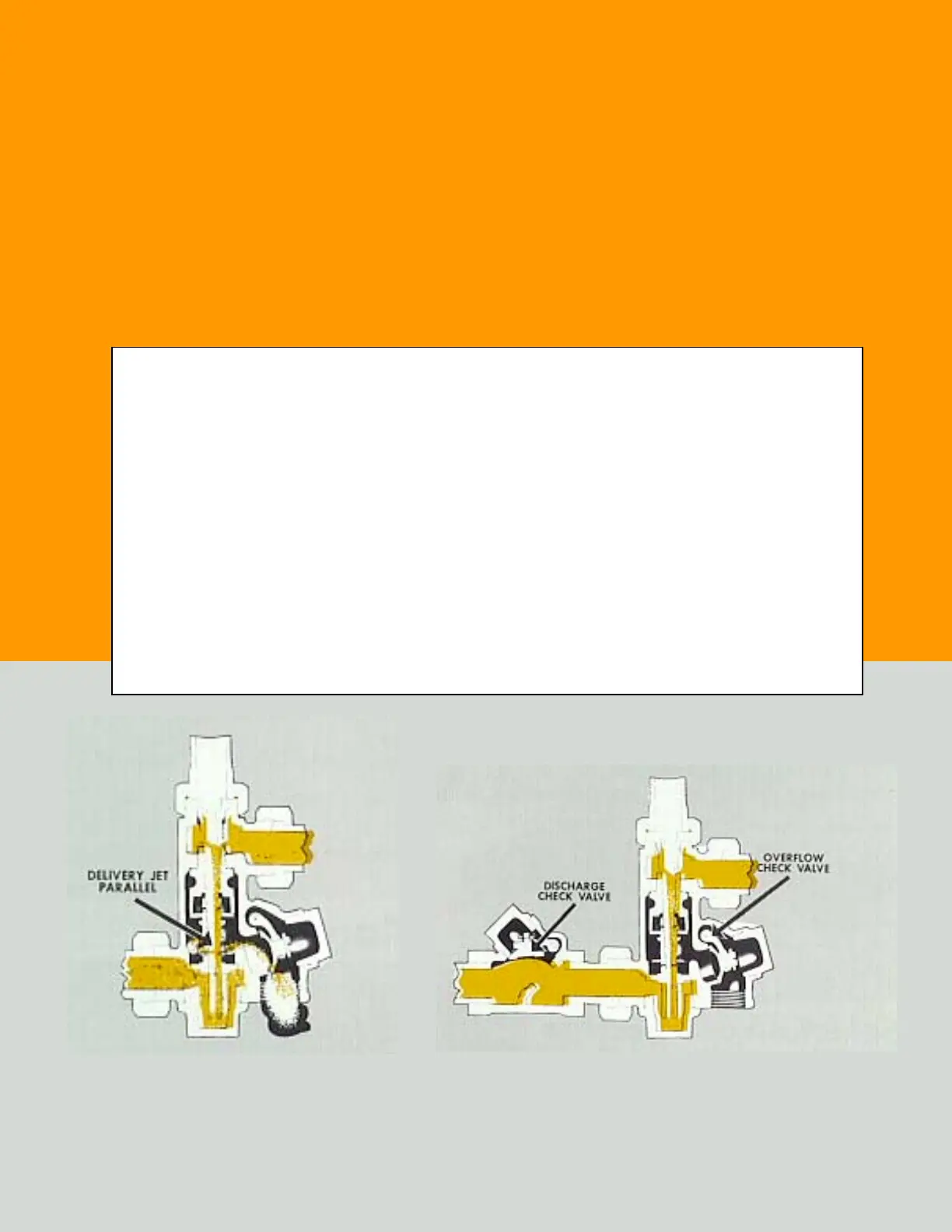

The energy contained in the water passing through delivery jet is sufficient to

build up a pressure, greater than the boiler pressure, causing water to flow

through the discharge check valve into the boiler. When flow into the boiler is

established the overflow valve closes automatically and prevents the entrance

of air which would disrupt operation of injector. Total operating cycle requires

only a few seconds.

*Formerly Penberthy Injector Co.

3

NORTHEAST CONTROLS INCORPORATED

TEL: 201-419-6111 ext. 23 for Venturi Group

NORTHEAST CONTROLS INCORPORATED

TEL: 201-419-6111 ext. 23 for Venturi Group

Loading...

Loading...