See Page 9 for Installation Data and pate 11 for Repair Parts

INSTALLATION INSTRUCTIONS

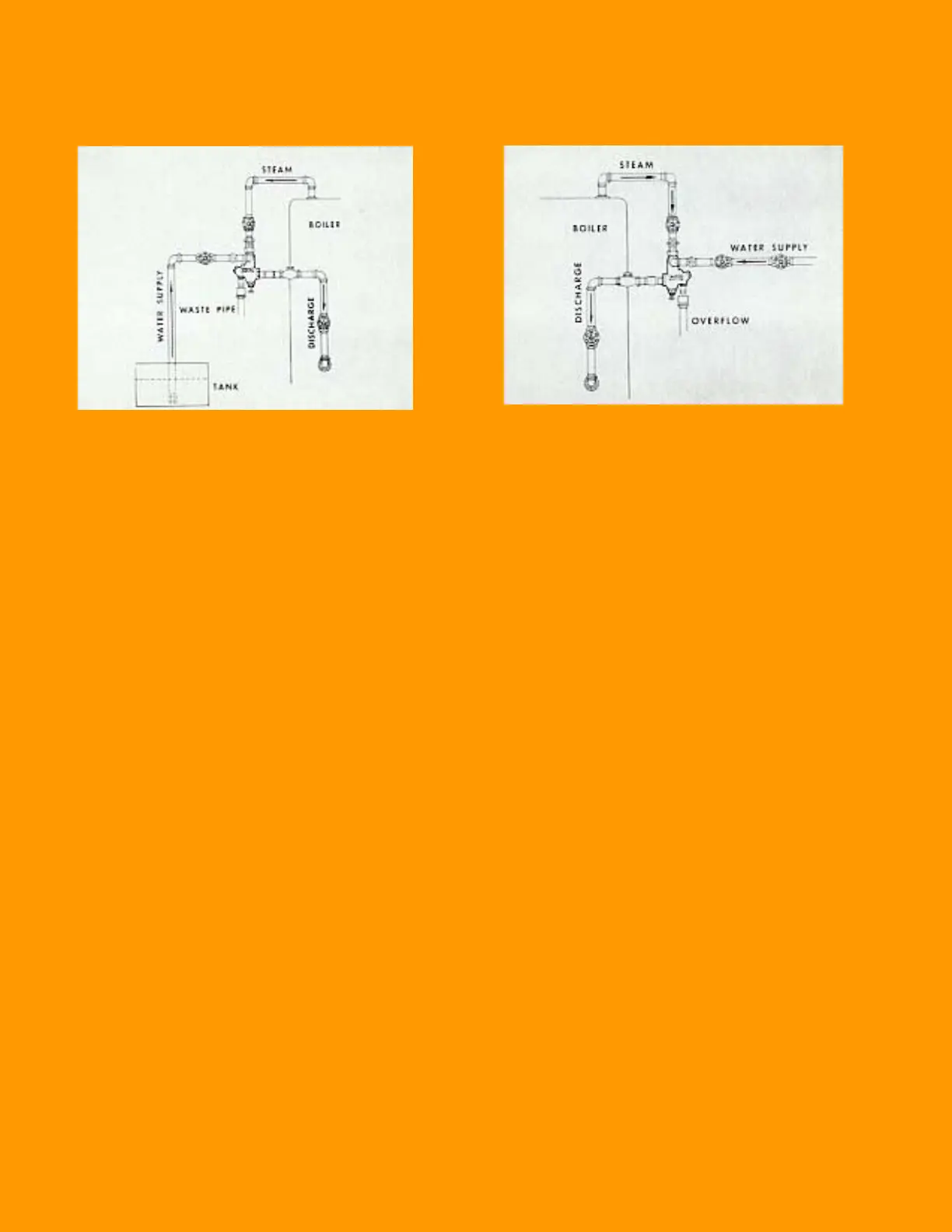

FOR SUCTION LIFT FOR WATER PRESSURE SUPPLY

Penberthy Injectors are used with any t ype of water supply.

To obtain the best possible results the following points should

be considered.

1. The steam pipe should be an independent line, the same

size as the injector connection and connected to the

boiler at the highest possible point.

2. If injector operates on a suction lift, the water supply pipe

should be one size larger than the injector connection ex-

cept on very short lifts. On long suction lifts, a pipe 2 sizes

larger with a f oot valve installed at end of pope i s recom-

mended. A glove valve, the full size of supply pipe, should

be installed in this line and the strainer which is provided

each injector should be attached at the end. It is very im-

portant tha the water supply pipe connection including the

valve stem packing be free from leaks.

Penberthy Injectors are used with any t ype of water supply.

To obtain the best possible results the following points should

be considered.

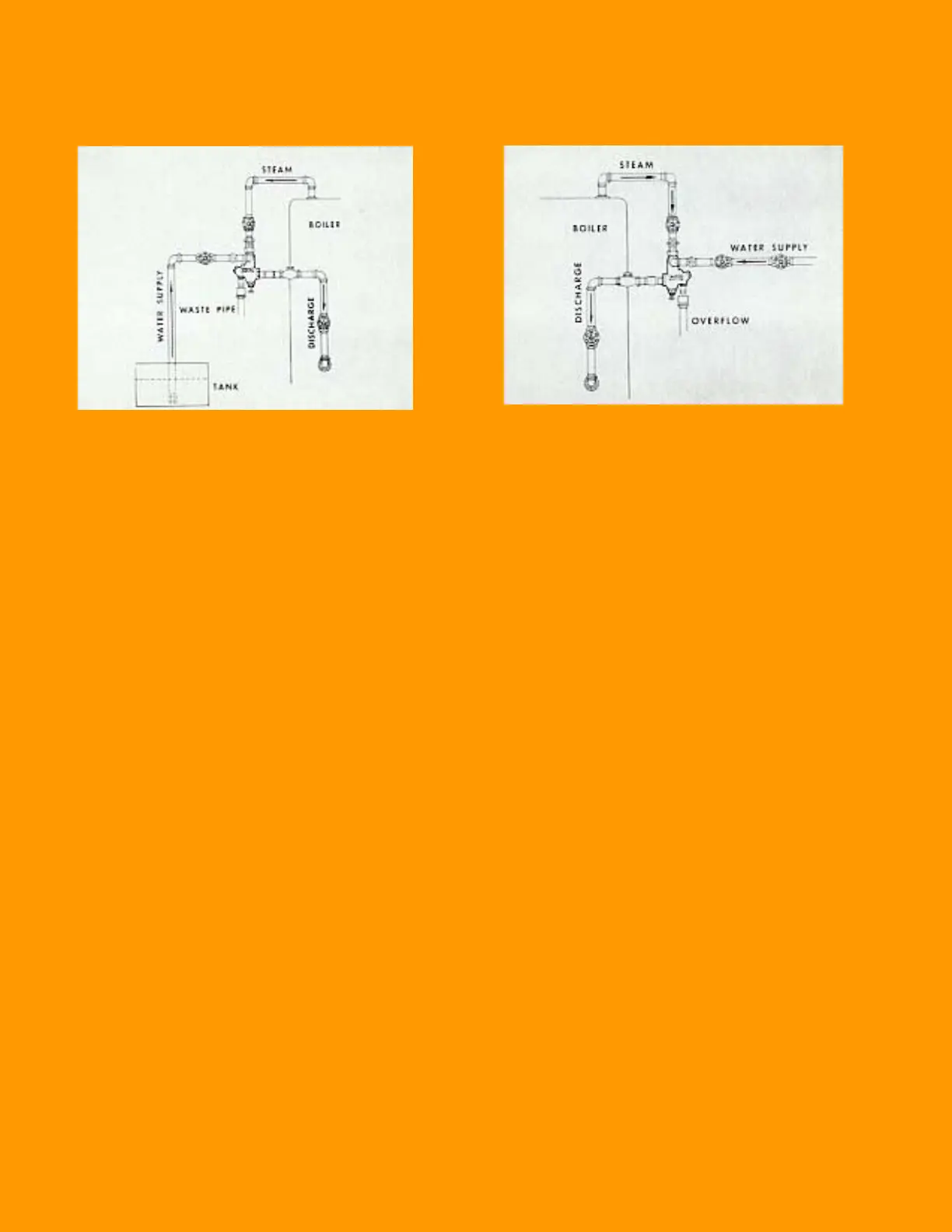

3. If injector water supply is taken from city water mains or an

overhead tank, better regulation of water may be obtained

if two globe valves are i nstalled in the water supply line.

The valve nearest the injector is used to regulate the wa-

ter supply while the second valve is adjusted permanently

to provide the most desirable pressure reduction.

4. The delivery pipe should be the same size as the injector

connection or larger if desired. A swing check valve and a

globe valve should be installed in this line, which should be

as direct and as f ree from elbows as the installation will

permit.

OPERATION

To Start:

Fully open the water supply valve and the discharge

valve. Next, fully open the steam valve. If water continues to

come out of overflow connection, throttle the water supply

valve until is stops. On low pressure operation it may be nec-

essary to throttle the water supply valve in order t o establish

injector operation. On high pressure operation it is satisfactory

to throttle the steam valve until the water supply pipe is

rimed

but under all other conditions the steam valve should

be wide open and regul ation of flow governed by the water

supply valve.

To Stop:

Close the steam valve. The water supply valve

need not be closed unless supply water is under pre ssure.

The discharge line valve needs to be closed only as a precau-

tionary measure as the check valve will prevent back flow from

the boiler.

9

NORTHEAST CONTROLS INCORPORATED

TEL: 201-419-6111 ext. 23 for Venturi Group

NORTHEAST CONTROLS INCORPORATED

TEL: 201-419-6111 ext. 23 for Venturi Group

Loading...

Loading...