1401 North Plano Road, Richardson, Texas 75081

Phone: 972-234-3202 | Fax: 972-497-0441

Use care when touch-ing

the exterior of an oper-

ating motor. Modern motors normally run

hot. They are designed to operate at higher

temperatures. This is a normal con-dition

but they may be hot enough to be painful or

injurious to the touch.

Use low pressure grease

guns only. High pressure

guns tend to blow out or unseat bearing

seals, leaving the bearing open to collect

grime, dust and foreign particles.

PENNBARRY 3

2. Check motor and bearing

temperatures for excessive heat.

If any problem is indicated, TURN OFF

POWER TO UNIT IMMEDIATELY. Lock

out the electrical supply, check carefully

for the cause of the trouble and correct

as needed. Even if the fan appears to be

operating satisfactorily, shut down after a

brief period and check all fasteners, set-

screws and keys for tightness.

During the rst eight (8) hours of opera-

tion, check the fan periodically for exces-

sive vibration or noise. At this time, also

check motor input current and motor bear-

ing temperatures to insure that they do not

exceed manufacturer’s recommenda-tions.

After eight hours of satisfactory operation,

shut down the fan and lock out the electri-

cal power to check the following items and

adjust if necessary:

a. All set-screws, keys and fasteners.

b. Drive coupling alignment.

c. Belt alignment.

d. Belt tension.

Maintenance

Do not attempt maintenance on fan until

the electrical supply has been completely

disconnected. If a disconnect switch has

not been provided, remove all fuses from

the circuit and lock the fuse panel so they

cannot accidentally be replaced.

Lubrication is a primary maintenance

responsibility. Check all bearings periodi-

cally. Inspect belts for tightness. If the fan

is installed in a corrosive or dirty atmos-

phere, periodically clean the impeller, inlet

and other moving parts.

FAN SHAFT LUBRICATION

Fan shaft bearing pillow blocks are fur-

nished in either the prelubricated sealed-

for-life type or the greasable type depend-

ing on what was ordered. The prelubricat-ed

type requires no servicing for 7 to 10 years

of normal use and the greasable type are

factory greased eliminating the need for

greasing initially. Follow the lubri-cating

schedule recommended by the fac-tory.

When required, apply grease while the

shaft is rotating. This practice should not

supersede any safety considerations.

LUBRICATION SCHEDULE

Always follow the bearing manufacturer’s

recommended lubrication schedule. If

none is available us the following general

schedule.

a. Under average conditions where ambi-

ent temperatures do not exceed 120°F.,

lubrication is required 1 to 2 times a year.

b. Under dirt laden atmospheres or where

there is a temperature range of 120°F to

150°F, lubrication is required from 3 to 6

times a year.

c. Under extreme temperature conditions

and extremely dirty atmospheres, lubrica-

tion should be at least once or twice a

month.

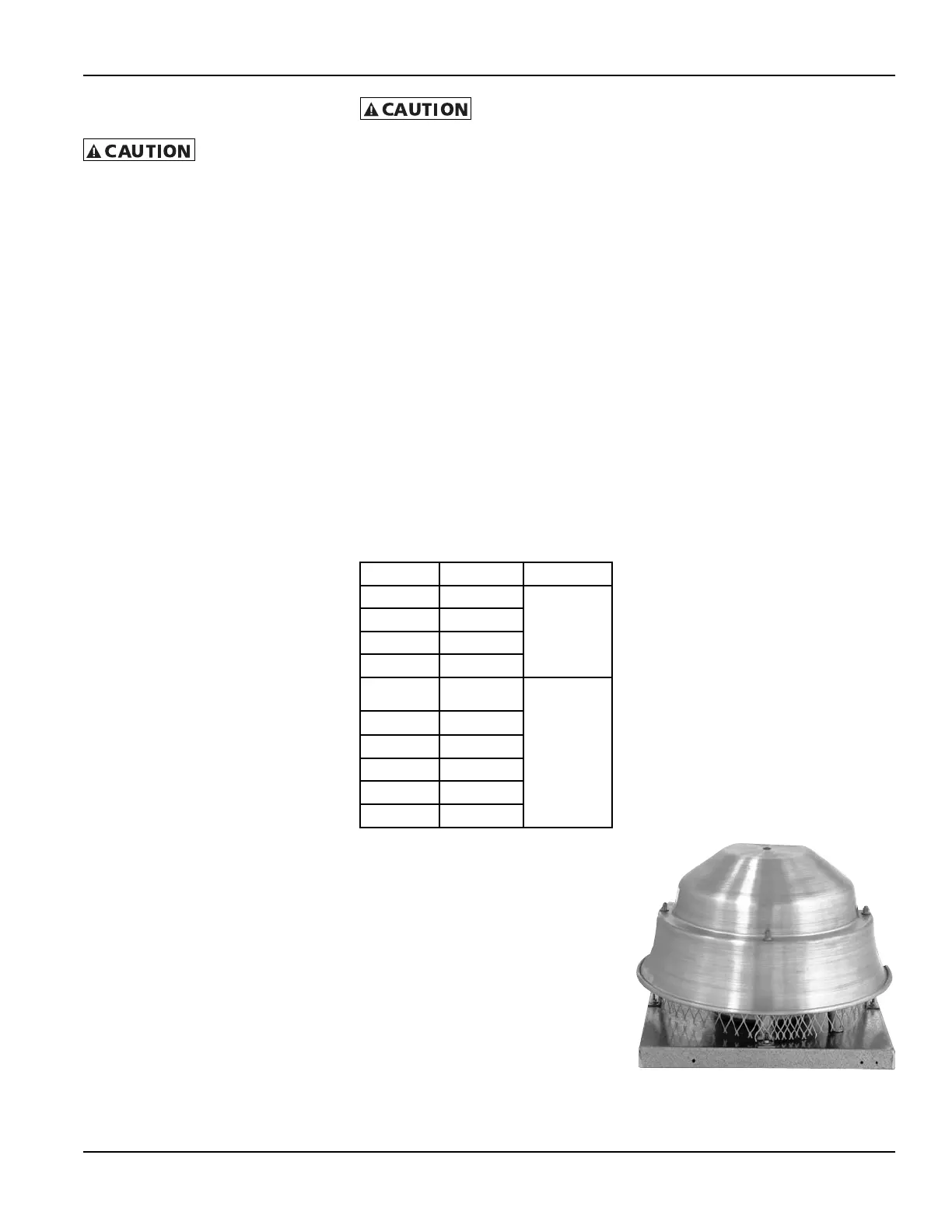

Table 1: Recommended Lubricants

MOTOR LUBRICATION

In general, standard motors are furnished

with prelubricated, sealed-for-life ball bear-

ings which require no lubrication for 7 to

10 years of normal service. Where motors

have been ordered with greasable bear-

ings, these bearings are factory lubricated

and require no attention for one year under

normal conditions. If grease relief ttings

are provided, remove them when perform-

ing maintenance to allow grease to ow

out. Whenever possible, apply grease while

the motor is running. This practice should

not supersede any safety considerations.

DO NOT OVER GREASE, as most lubri-

cants deteriorate motor windings, thereby

reducing motor life.

Hidden Danger

In addition to the normal dangers of rotat-

ing machinery, fans present an additional

hazard in their ability to suck in not only air,

but loose material as well. Solid objects can

pass through the fan and be discharged

by the impeller as potentially dangerous

projectiles. Therefore, screen intake to

ductwork, whenever possible, to prevent the

accidental entrance of solid objects. Never

open access doors to a duct system with the

fan running.

When starting the fan for the rst time, com-

pletely inspect the ductwork and inte-rior

of the fan (with power locked off), to make

certain there is no foreign material which

can be sucked into or blown through the

ductwork.

Guards

All fans have moving parts which require

guarding in the same way as other moving

machinery.

Where the fan is accessible to untrained per-

sonnel or the general public, use maximum

safety guards, even at the cost of some

performance loss. Unprotected fans located

less than 7’ above the oor also require

guarding as specied in the Occupational

Safety and Health Act (OSHA).

PennBarry recommends the use of guards

on all exposed nonducted fans, ceiling and

wall mounted.

Centrifugal fans may be connected directly

to ductwork which will prevent contact with

the internal moving parts, but when the inlet

or outlet is exposed, install a suitable guard.

Operation & Maintenance Manual

Domex, Centrifugal Roof, Direct & Belt Drive Exhausters

Manufacturer Product Temp. Range

BP LG-#P-1

Below 32° F

(0° C)

Gulf Gulfcrown EP-1

Imperial Oil Unirex EP-1

Shell Alvania R-1

BP

Energrease,

MPMK11

32° F to 150° F

(0° C to 66° C)

Gulf Gulfcrown EP-2

Imperial Oil Unirex EP-2

Shell Alvania R-3

Sun Oil Sun Prestige 42

Texaco Regal AFB2

Loading...

Loading...