13

www.PennBarry.com

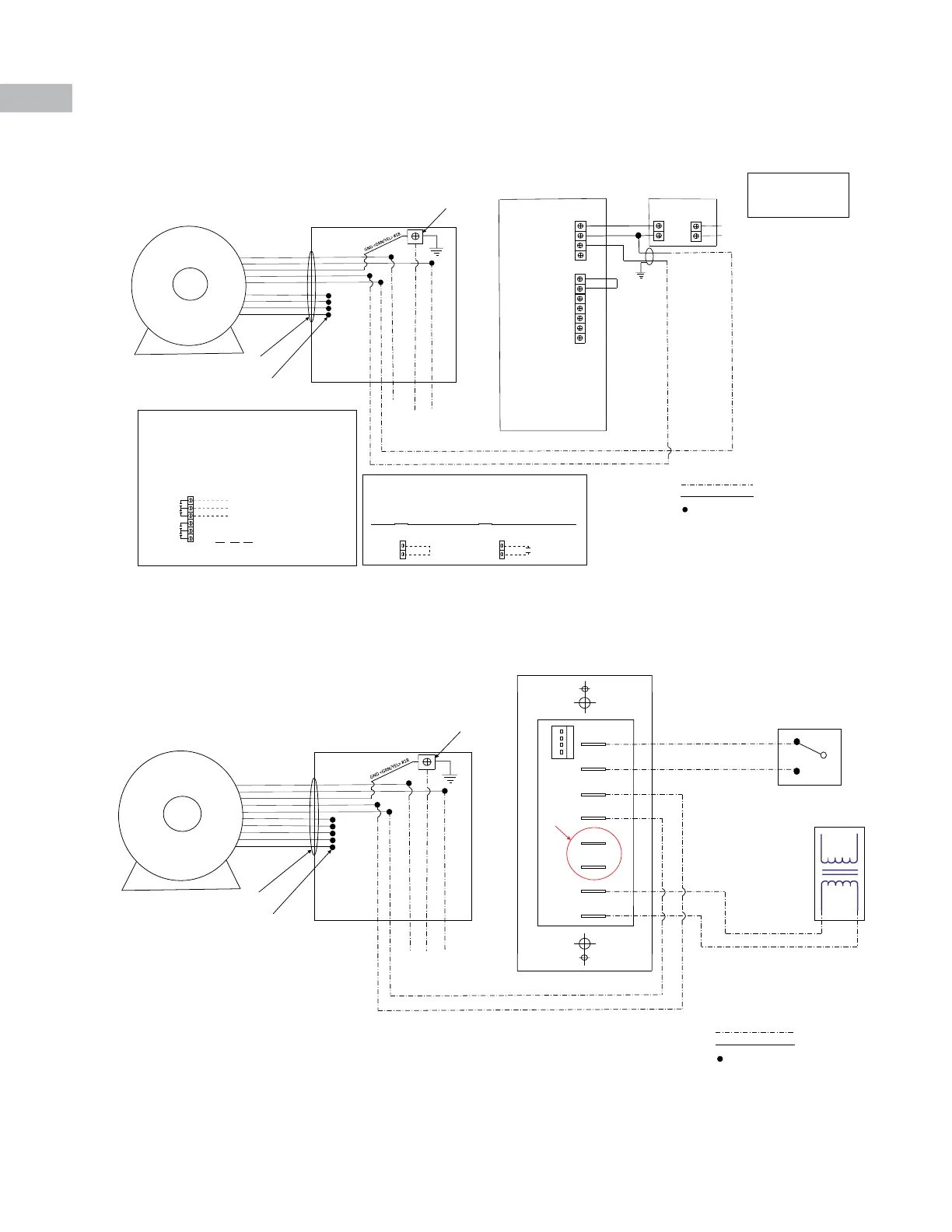

WIRING HARNESS – ECM

3) T.E. Motors 120v/240v/460v Single Phase (with iQ-IPCM controller)

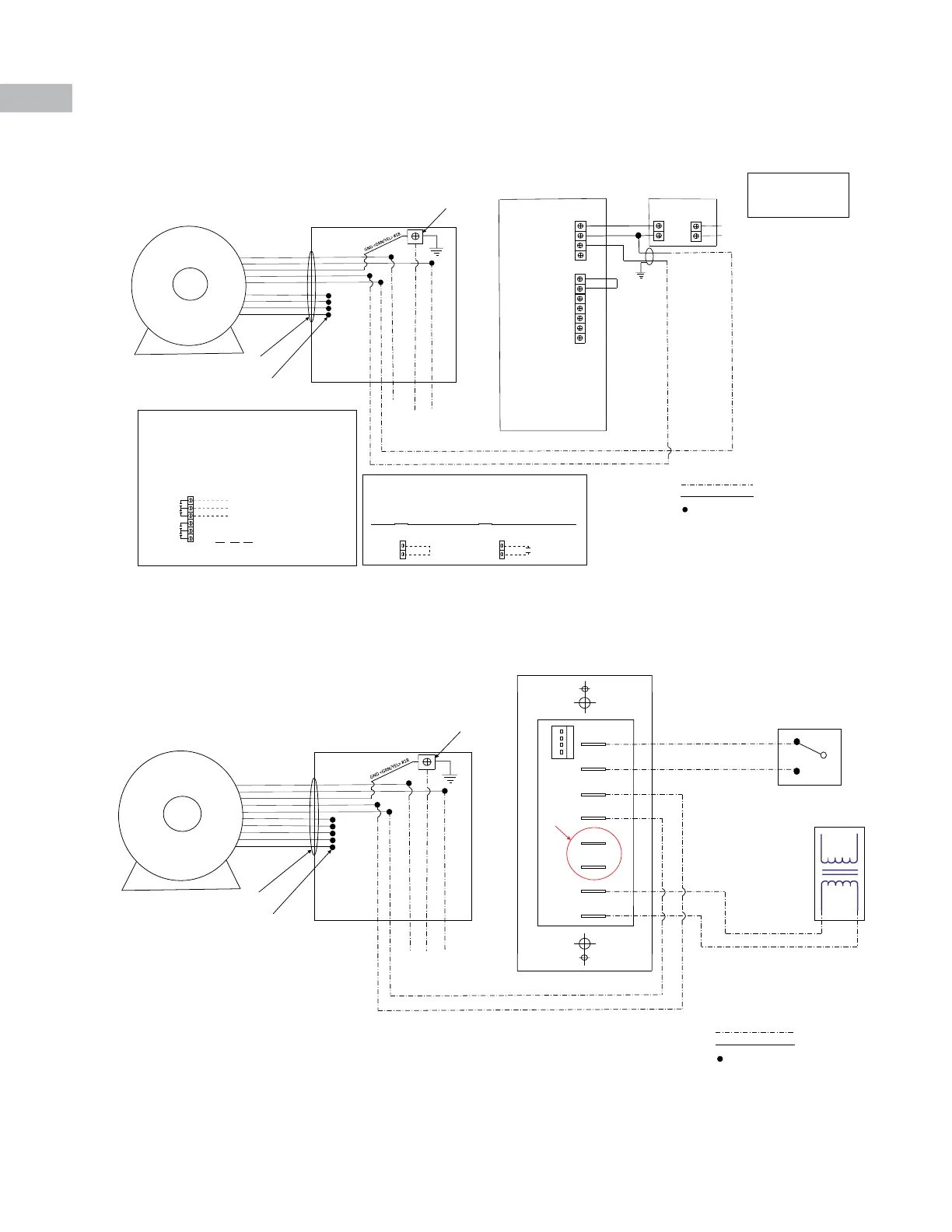

4) T.E. Motors 120v/240v/460v Single Phase (with iQ-MS controller)

This drawing illustrates our understanding of order requirements. When approved, it represents details for fabrication, as such,

PennBarry will not be responsible for revisions in the eld or other changes after release for fabrication. Published and protected by

PennBarry, Plano, TX. All rights reserved. May not be reproduced partially or in full without permission from the publisher. No rights

conveyed to manufacture partially or in full, use or sell either the method of construction represented or any invention in any way

related thereto.

EXC

COM

VOUT

mA

D l 1

D_COM

D l 2

AN1

A_ COM

AN2

A_ COM

Terminal Block 1

Terminal Block 2

+( 24VDC )

- ( Common )

Power

Supply

24 VDC Power Supply

L1 <BLK> #18

L2/N <RED> #18

GND <GRN/YEL> #18

COMMON <BLUE> #18

ANALOG IN <BRN> #18

PRGR#2 <WHT> #18

PRGR#3 <YEL> #18

PRGR#4 <ORG> #18

PRGR#5 <PRP> #18

COM

+10VDC

L1

GND

L2N

COMMON<BLUE> #18

ANALOG IN <BRN> #18

L1 <BLK> #18

L2/N <RED> #18

JUNCTION BOX

WIRE CLAMP

CONNECTIONS TERMINATED

AND FOR FACTORY USE ONLY

Enable Jumper

Low Voltage 0-10

VDC, 2 x 18 AWG,

<300 Shielded

Analog Speed Signal

to EC Motor or VFD

Oponal Status Connecons

The relays will energize when all of the following condions are met:

1. The IPCM is energized

2. The corresponding input is enabled

3. The system pressure is within the high and low pressure limits

Figure 9: Example Terminal Block #3 wiring connecons when DI1 input

is used and RLY1 output is use to drive external device/appliance

DI1 = RELAY 1

DI2 = RELAY 2

Terminal Block 3

RUNNING / NORMAL OUTPUT

EXTERNAL SIGNAL INPUT

DISABLED / ALARM OUTPUT

Field Wired

RLY 1 NO

RLY 1 COM

RLY 1 NC

RLY 2 NO

RLY 2 COM

RLY 2 NC

GROUNDING BLOCK

FIELD WIRED, BY OTHERS

FACTORY WIRED

WIRED CONNECTION

**Note, Power Supply IN can be

selected as 24VAC, 115/230VAC (Low

Voltage), or 277/460VAC (High

Voltage – Single Phase only). Power

Supply can also be, “by others.”

Oponal Enable Connecons

A B

IPCM IPCM

Terminal Block 2

DI1 (Enable #1)

Install jumper

for connuous

operaon

Install dry contact or

switch to enable disable

IPCM

D_COM

DI1 (Enable #1)

D_COM

Terminal Block 2

The majority of IPCM systmes run in a connuous modulang mode of operaon with

DI1 jumped to D_COM on terminal block #2. See illustraon A below. When the ability

to enable and disable the system is desired, a dry contact or switch will need to be

wired between DI1 and D_COM. Refer to illustraon B below.

The IPCM has two dry SPDT relay contacts for status output. Each relay

corresponds to a digital input. Relay 1 is acve when DI1 is enabled and relay 2 is

acve when DI2 is enabled.

TRANSFORMER PROVIDED

BY OTHERS.

ANALOG CONNECT TO EC

MOTOR 0-10VDC

OPTIONAL

24VAC OUTPUT

HI-LO

COMMON

24VAC

COMMON

NEUTRAL

MOTOR

SWITCH PROVIDED

BY OTHERS

L1 <BLK> #18

L2/N <RED> #18

GND <GRN/YEL> #18

COMMON <BLUE> #18

ANALOG IN <BRN> #18

PRGR#1 <GREEN> #18

PRGR#2 <WHT> #18

PRGR#3 <YEL> #18

PRGR#4 <ORG> #18

PRGR#5 <PRP> #18

COM

+10VDC

L1

GND

L2N

COMMON <BLUE> #18

ANALOG IN <BRN> #18

L1 <BLK> #18

L2/N <RED> #18

JUNCTION BOX

WIRE CLAMP

CONNECTIONS TERMINATED

AND FOR FACTORY USE ONLY

GROUNDING BLOCK

FIELD WIRED, BY OTHERS

FACTORY WIRED

WIRED CONNECTION

24VAC

NEUTRAL

24VAC

LINE VOLTAGE

NO-SETPOINT 1

NC-SETPOINT 2

Loading...

Loading...