– 18 –

CAUTION:

Do NOT apply excessive force or use a sharp object in an attempt to

unblock a clogged channel as the endoscope channel could become

damaged. Whenever channel damage is suspected, the endoscope should

be leak tested.

If repeated attempts to flush the air/water system are unsuccessful, do

not attempt to use the endoscope on a patient.

Contact the PENTAX service facility.

h) If the air/water feeding valve does not function properly, does not move smoothly

or feels “sticky”, remove the valve and apply a very small amount of silicone oil

lubricant (OF-Z11) onto all the O-rings. Do NOT use excess oil, avoid “blobs”,

large drops and/or squirts of oil directly onto the metal valve stems - instead,

simply place a small droplet of oil on one’s sterile gloved forenger and gently

swirl between thumb and forenger. Next place the valve with O-ring in-between

thumb and nger and gently rotate the valve so that the oil is evenly applied to

the outer edges of each O-ring. Make sure the oil is applied to all O-rings and

wipe off all excess.

Do NOT apply excess oil. Doing so can allow for inadvertent migration of the

oil inside channels or other areas not intended to be lubricated.

NOTE:

Prior to clinical use, it is important that the entire air channel system be

dry. Failure to thoroughly dry the air system could result in an unclear or

blurry image caused by very fine droplets of moisture being swept over

and/or onto the objective lens at the distal end of the endoscope.

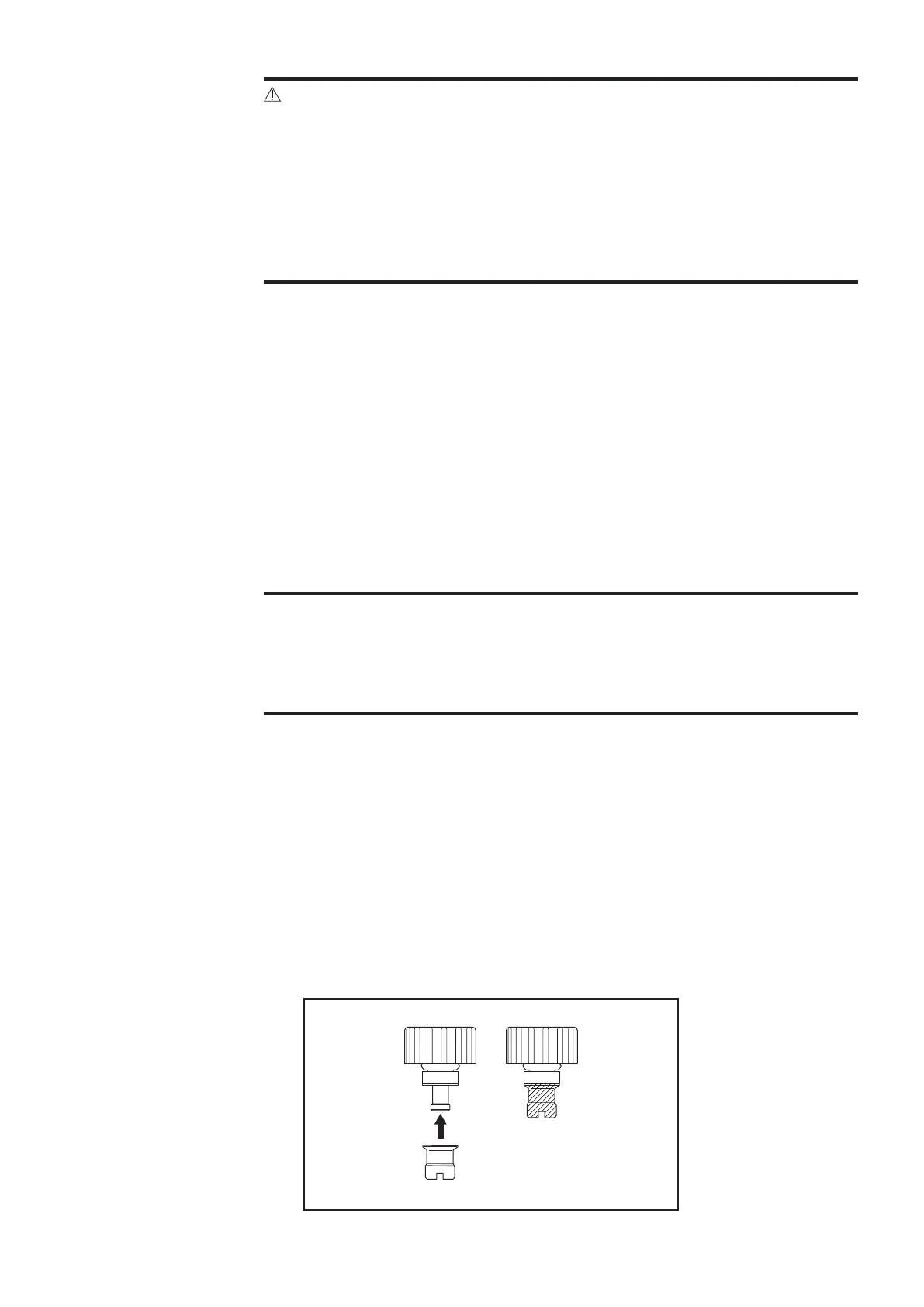

5) Inspection of Water Jet (Endoscope with water jet system)

a) Prior to use, the water jet check valve adapter (OE-C12) should be inspected.

Open the water jet connector cap (OF-B118). Turn the water jet adapter

counterclockwise and remove it from its cylinder. Make sure that the black

check-valve (OE-C14) is properly attached to the bottom of the water jet check

valve adapter.

If the check-valve is missing or not attached properly, correctly reposition the

check-valve by turning it several times on the water jet adapter unit.

For proper positioning, there should be no clearance (gap) between the check-

valve and the water jet check valve adapter stem.

(1) OE-C12

(2) OE-C14

Figure 2.11

Loading...

Loading...