INSUFFICIENT POWER:

Probable Cause Solution

Dirty or clogged air passages ......... Flush and lubricate tool, drain air tank and supply line

Insufficient air supply ...................... Increase line pressure, Make sure compressor

matches tool's air pressure and consumption needs

Air leakage...................................... Use PTFE tape at all fittings and joints. Check tool for

worn or damaged O-rings & seals.

Worn/damaged wear & tear parts ... Replace as necessary.

Tool matching ................................. Be sure you are using a tool suited for the torque

requirements of the job at hand.

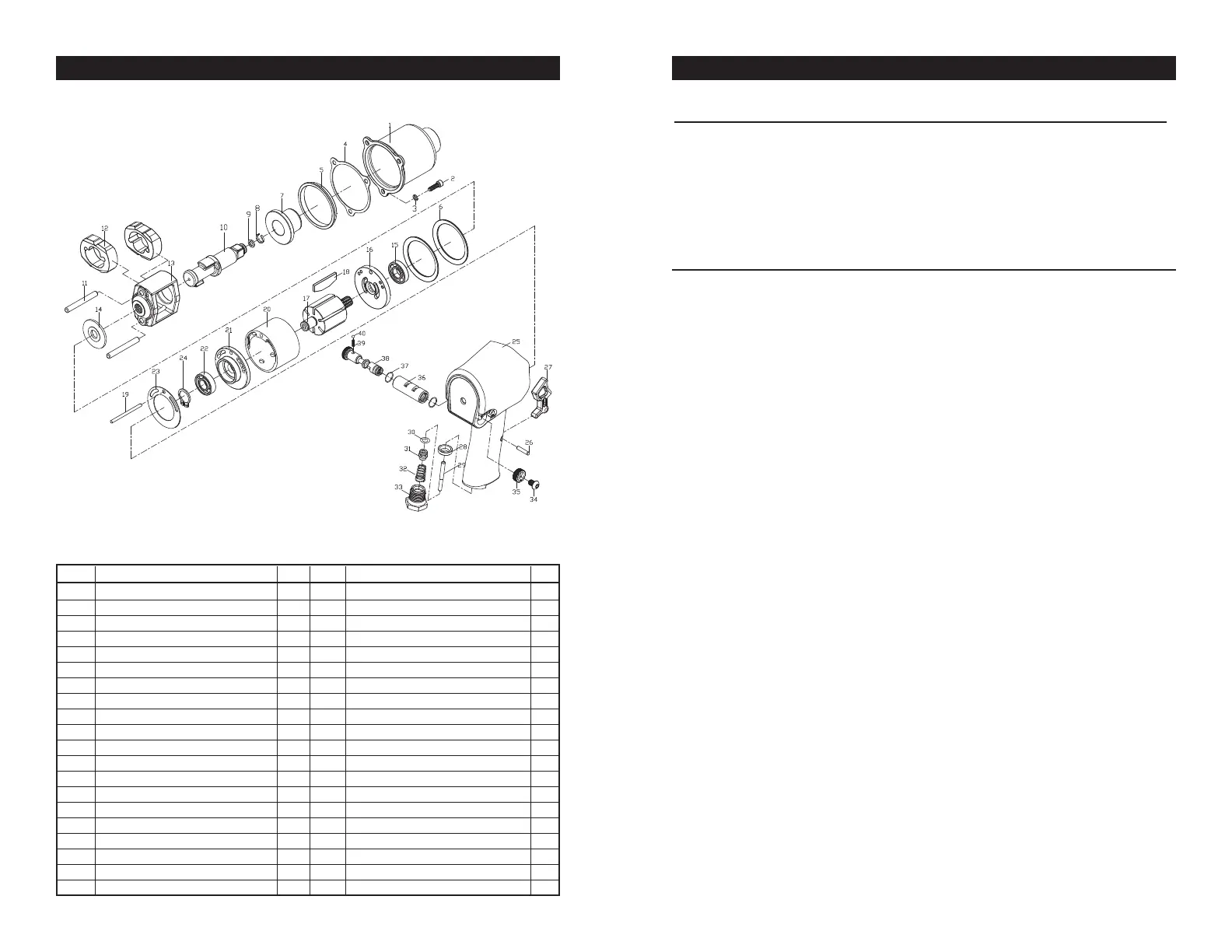

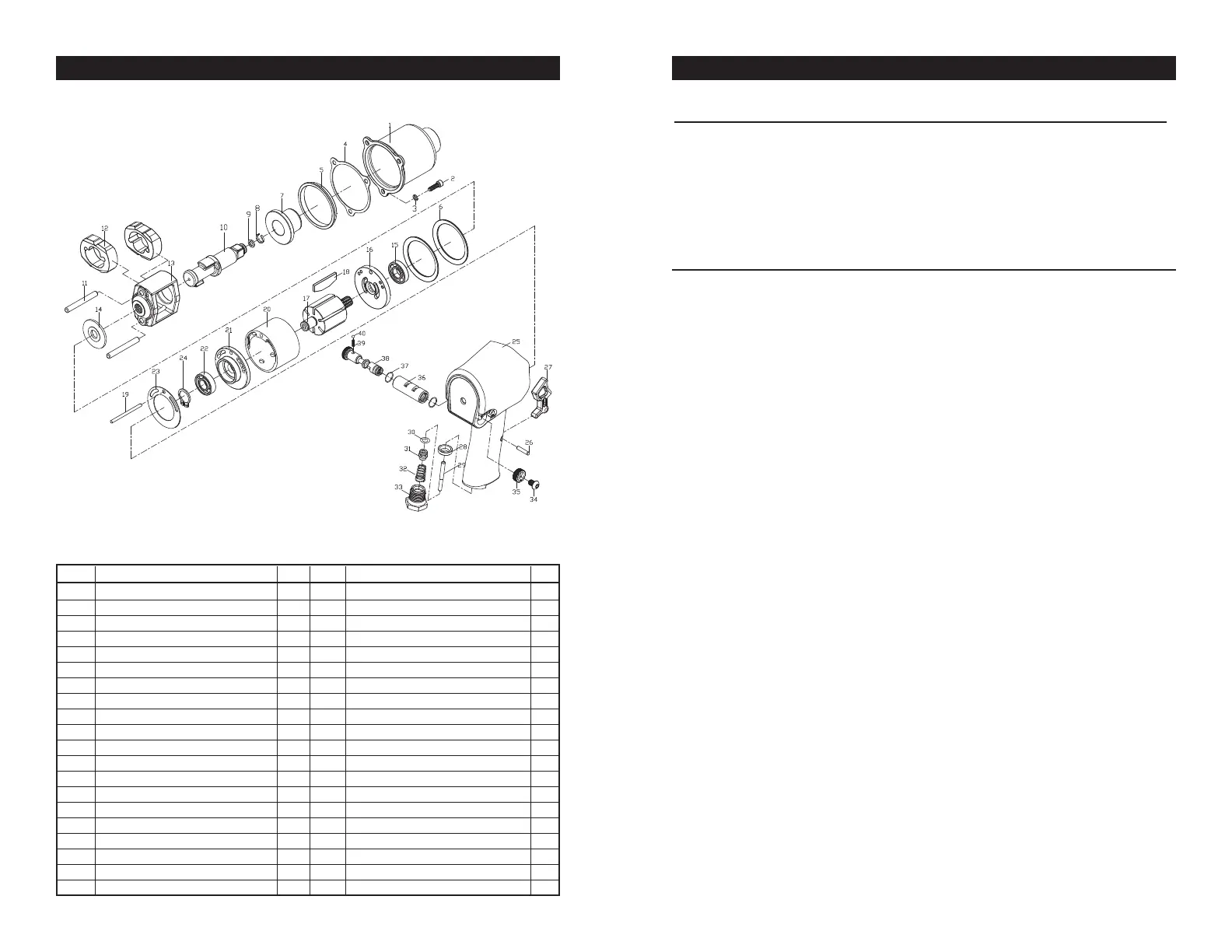

TROUBLESHOOTINGPARTS LIST

INDEX DESCRIPTION QTY INDEX DESCRIPTION QTY

1 Protective Rubber 1

2 Nut 1

3 Gasket 1

4 Seal Pad 1

5 Washer 2

6 V-Gasket 1

7 Anvil Bushing 1

8 Anvil Collar 1

9 O-Ring 1

10 Drive Shaft 1

11 Hammer Pin 1

12 Hammer Dog 1

13 Hammer Cage 1

14 Hammer Gasket 1

15 Front Bearing 1

16 Front Cover 1

17 Rotor 1

18 Rotor Blade 1

19 Cylinder Pin 1

20 Cylinder 1

21 Rear Cover 1

22 Rear Bearing 1

23 Rear Gasket 2

24 C-Ring 1

25 Housing 1

26 Trigger Pin 6

27 Trigger 1

28 Inlet Valve Seat 1

29 Switch Pin 1

30 O-Ring 1

31 Inlet Valve 1

32 Spring 1

33 Housing Adapter 1

34 Screw 1

35 Air Regulator Knob 1

36 Valve Jacket 1

37 O-Ring 1

38 Spool Valve 1

39 Spring 1

40 Steel Ball 1

Loading...

Loading...