3. Disconnect the J1/P1 and J2/P2 connectors from

the ECM. Move the harness to a position that will

not allow the harness to accidentally move back

and make contact with any of the ECM pins.

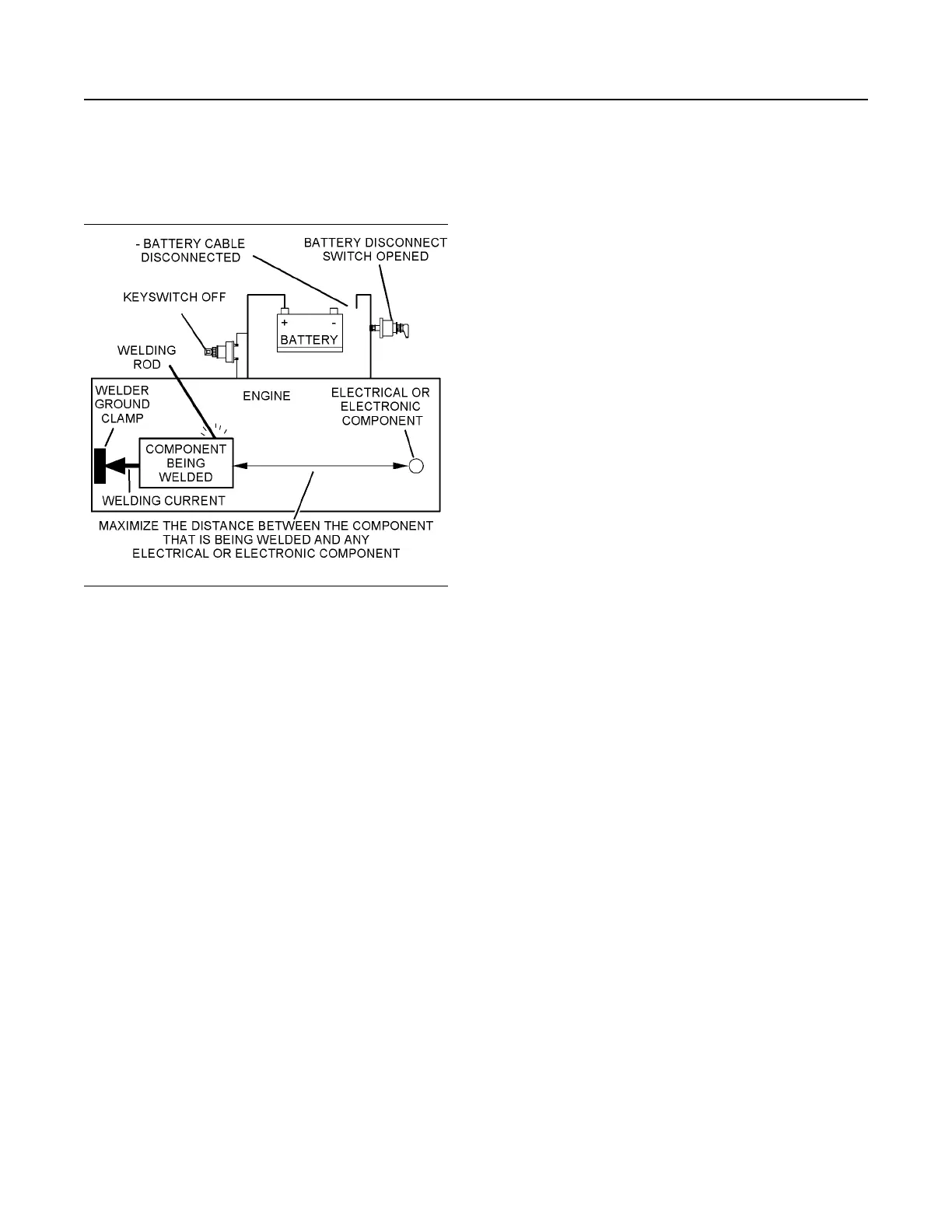

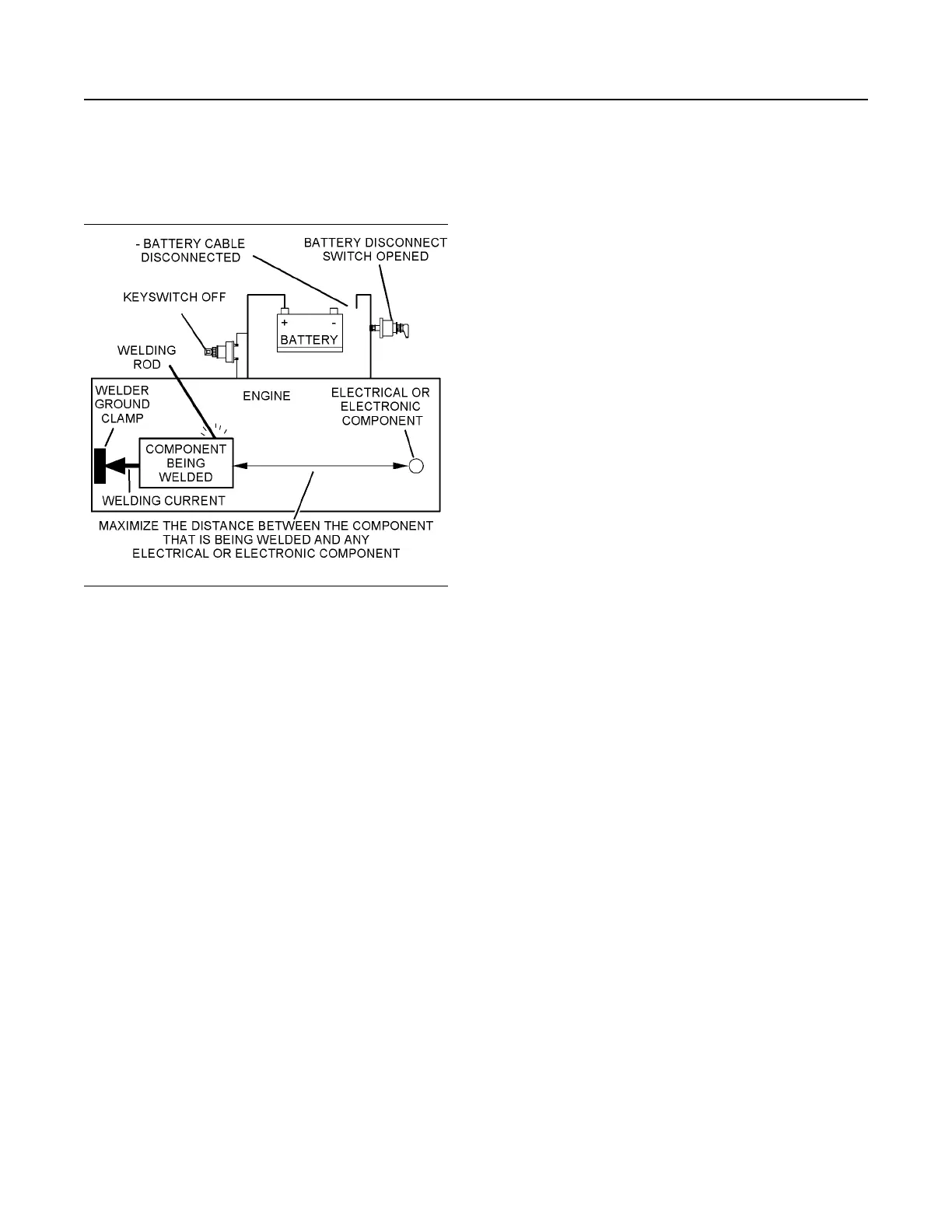

Illustration 37 g01143634

4. Connect the welding ground cable directly to the

part that will be welded. Place the ground cable as

close as possible to the weld in order to reduce the

possibility of welding current damage to bearings,

hydraulic components, electrical components, and

ground straps.

Note: If electrical/electronic components are used as

a ground for the welder, or electrical/electronic

components are located between the welder ground

and the weld, current flow from the welder could

severely damage the component.

5. Protect the wiring harness from welding debris and

spatter.

6. Use standard welding practices to weld the

materials.

SEBU8311-09

59

Maintenance Section

Welding on Engines with Electronic Controls

Loading...

Loading...