• Cavitation of the water pump

For optimum performance, Perkins recommends a

50 percent by volume of glycol in the finished coolant

(also referred to as 1:1 mixture).

Note: Use a mixture that will provide protection

against the lowest ambient temperature.

Note: 100 percent pure glycol will freeze at a

temperature of −13 °C (8.6 °F).

Most conventional antifreezes use ethylene glycol.

Propylene glycol may also be used. In a 1:1 mixture

with water, ethylene and propylene glycol provide

similar protection against freezing and boiling. Refer

to Table 15 and refer to table 16 .

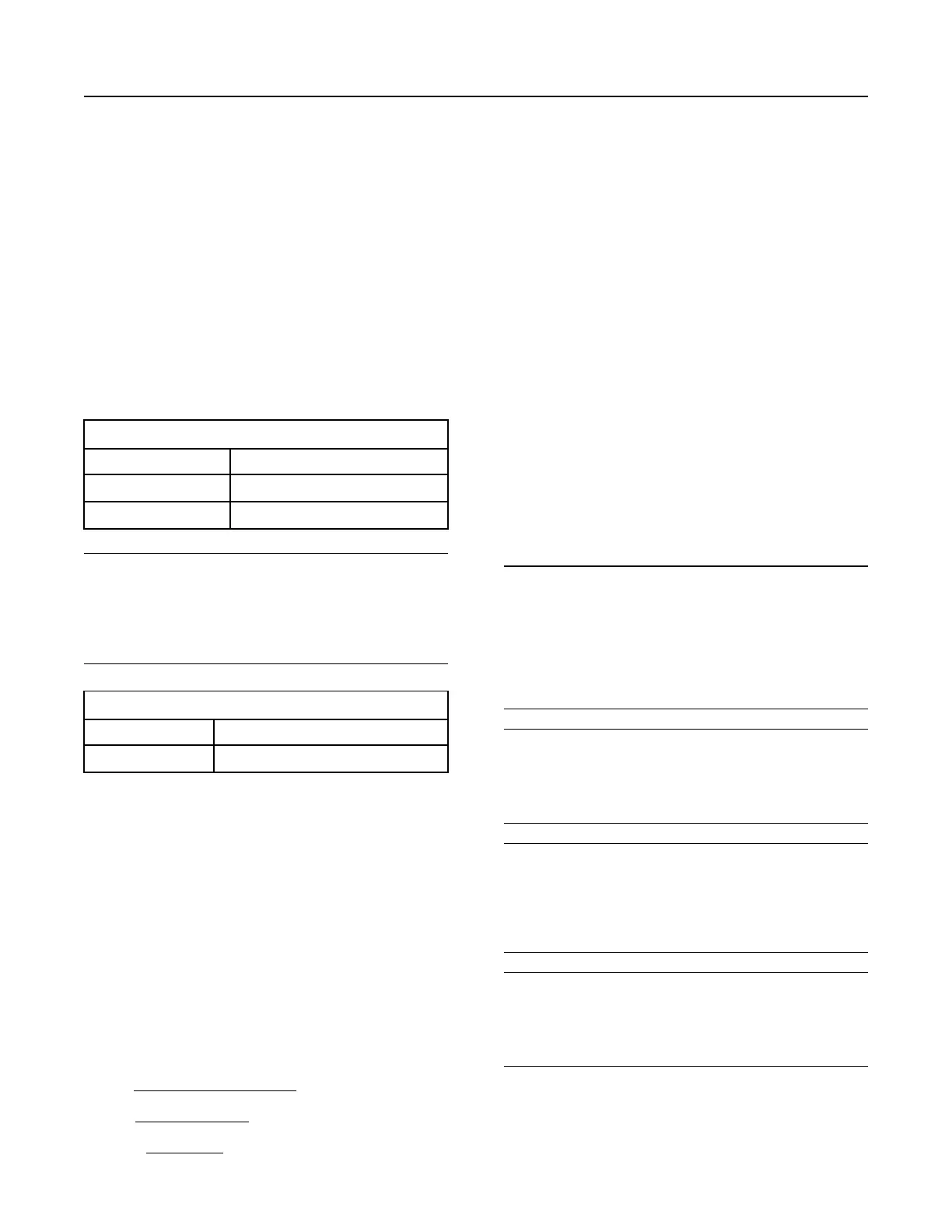

Table 15

Ethylene Glycol

Concentration Freeze Protection

50 Percent

−36 °C (−33 °F)

60 Percent

−51 °C (−60 °F)

NOTICE

Do not use propylene glycol in concentrations that

exceed 50 percent glycol because of the reduced

heat transfer capability of propylene glycol. Use ethyl-

ene glycol in conditions that require additional protec-

tion against boiling or freezing.

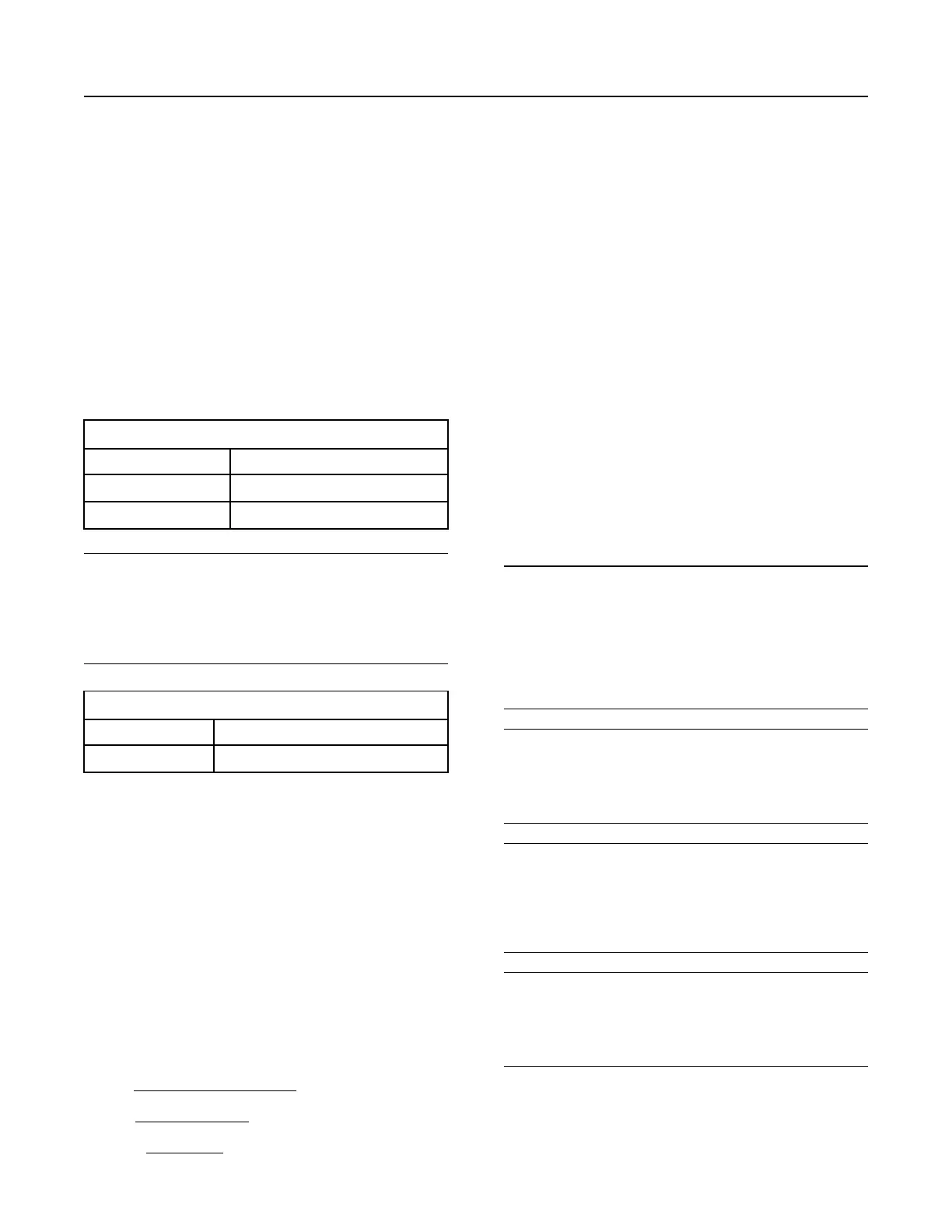

Table 16

Propylene Glycol

Concentration Freeze Protection

50 Percent

−29 °C (−20 °F)

To check the concentration of glycol in the coolant,

measure the specific gravity of the coolant.

Note: Some commercially available coolants are

based on alternative fluids, such as 1, 3-propanediol

(beta-propylene glycol, PDO), glycerin (glycerol), or

mixtures of these alternatives with ethylene/

propylene glycols. At the time of publication of this

document no industry standard exists for coolants

based on these chemicals. Until such standard/

specifications are published and evaluated by

Perkins, use of PDO, glycerine, or other alternative

coolants are not recommended in Perkins diesel

engines.

Coolant Recommendations

• ELC Extended Life Coolant

• SCA Supplement Coolant Additive

• ASTM American Society for Testing and

Materials

ELC - extended life coolant. A coolant that relies on

organic inhibitors for corrosion and cavitation

protection. Also called OAT coolant (Organic Acid

Technology).

SCA - supplemental coolant additive, concentrated

inorganic inhibitor package.

Extender - concentrated organic inhibitor package.

Conventional Coolant - a coolant that relies on

inorganic inhibitors for corrosion and cavitation

protection.

Hybrid Coolant - a coolant in which the corrosion and

cavitation protection is based on a mixture of organic

and inorganic inhibitors.

The following coolants are recommended for used in

Perkins diesel engines:

Preferred – Perkins ELC

Acceptable – A commercial heavy-duty antifreeze

that meets “ASTM D6210” or “ASTM D4985”

specifications.

NOTICE

The Perkins industrial engines with a NOx reduc-

tion system must be operated with a minimum

30% volume glycol-water mixture, Perkins recom-

mends 50% volume glycol-water mixture of water

and glycol. The 50% concentration allows the

NOx reduction system to operate correctly at

high ambient temperatures.

NOTICE

Do not use a commercial coolant/antifreeze that only

meets the ASTM D3306 specification. This type of

coolant/antifreeze is made for light automotive

applications.

NOTICE

A commercial heavy-duty antifreeze that meets

“ASTM D4985” specification requires a treatment

with an SCA at the initial fill. Read the label or the in-

structions that are provided by the manufacturer of

the product.

NOTICE

A commercial heavy-duty antifreeze that meets either

“ASTM D4985” or “ASTM D6210” specification re-

quires the SCA concentration to be checked at 500-

hour service intervals.

Perkins recommends a 50% mixture of water and

glycol. This mixture of water and glycol will provide

optimum heavy-duty performance as an antifreeze.

This ratio may be changed to 40% water to 60%

glycol if extra freezing protection is required.

M0132847 59

Maintenance Section

Fluid Recommendations

Loading...

Loading...