For inspections that are done with a suitable belt

frequency meter, install the belt frequency meter on

the span of the belt at Position “A” . Refer to table 24

for the correct frequency for a new belt or used belt

on a specific engine. Table 24 also gives the

approximate span of belt between crankshaft pulley

and alternator pulley.

Table 24

Alternator Belt Tension and Frequency

Engine Model

Approximate

Span (mm)

New belt Used Belt

Frequency (Hz)

Tension (Nm)

and (lb)

Frequency (Hz)

Tension (Nm)

and (lb)

403EA-11 Naturally

Aspirated

167 mm - 205 mm 190-200 Hz 400 N (90 lb) 160-170 Hz 300 N (67 lb)

403EA-11

Turbocharged

167 mm - 205 mm 222-229 Hz

425 to 456 N

(95.5 to 102.5 lb)

205-214 Hz

364 to 395 N

(82 to 89 lb)

403EA-17 215 mm - 225 mm 150-170 Hz

400 to 489 N

(90 to 110 lb)

130-145 Hz

267 to 356 N

(60 to 80 lb)

404EA-22 236 mm - 247 mm 130-150 Hz

400 to 489 N

(90 to 110 lb)

110-130 Hz

267 to 356 N

(60 to 80 lb)

Adjustment

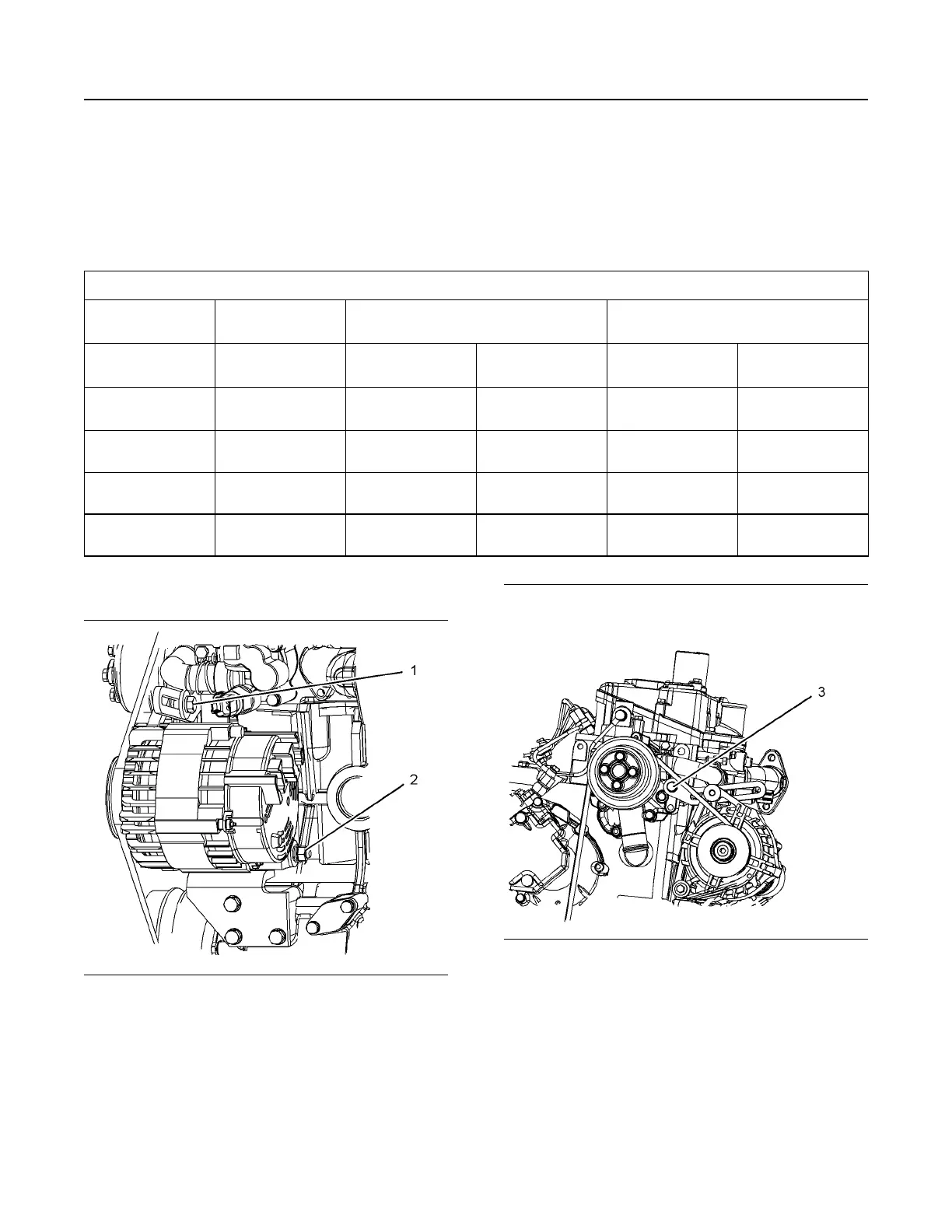

Illustration 44 g03383151

Typical example

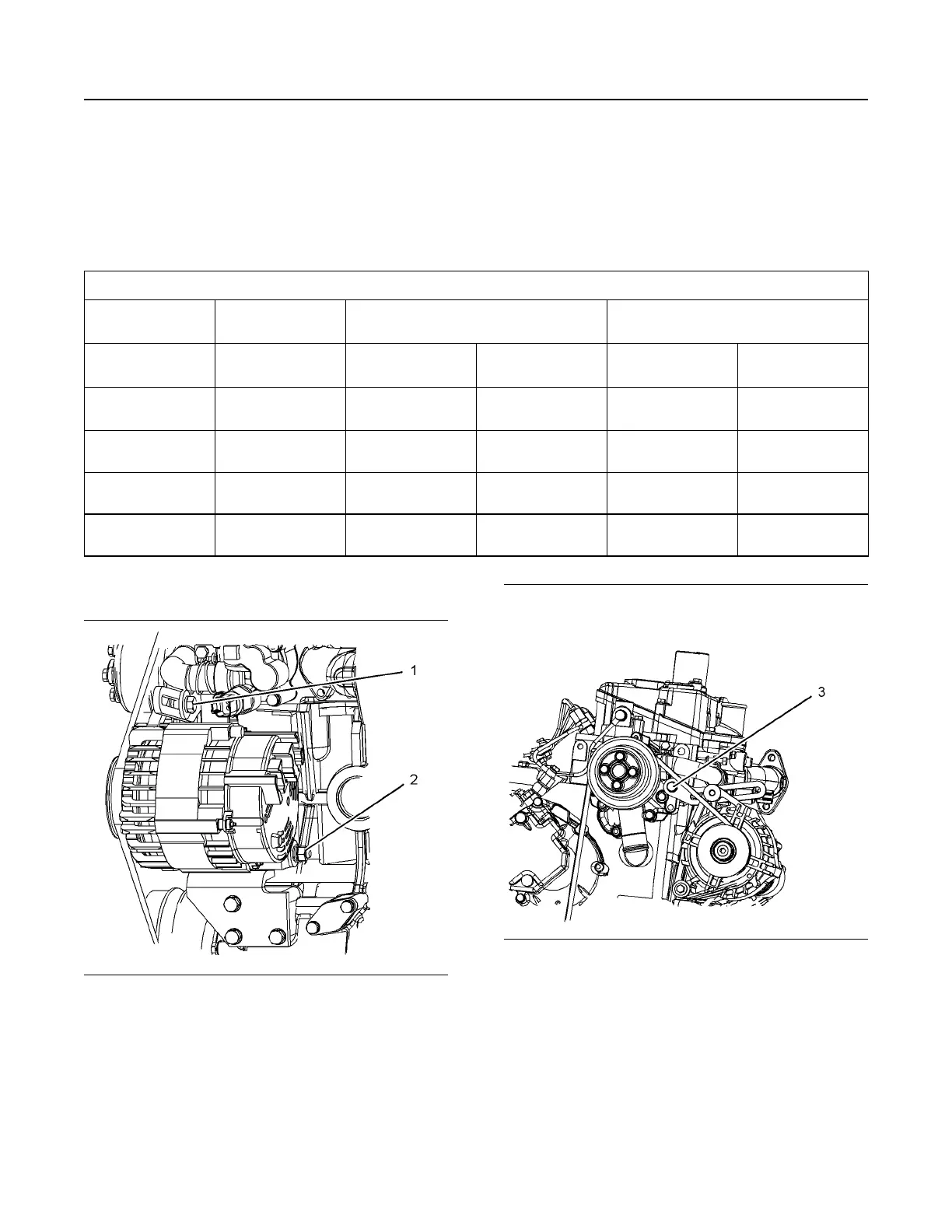

Illustration 45 g03383155

Typical example

1. Loosen adjusting bolt (1) and mounting bolt and

nut (2). Loosen bolt (3).

2. Move the alternator to increase or decrease the

belt tension.

M0132847

75

Maintenance Section

Alternator and Fan Belts - Inspect/Adjust

Loading...

Loading...