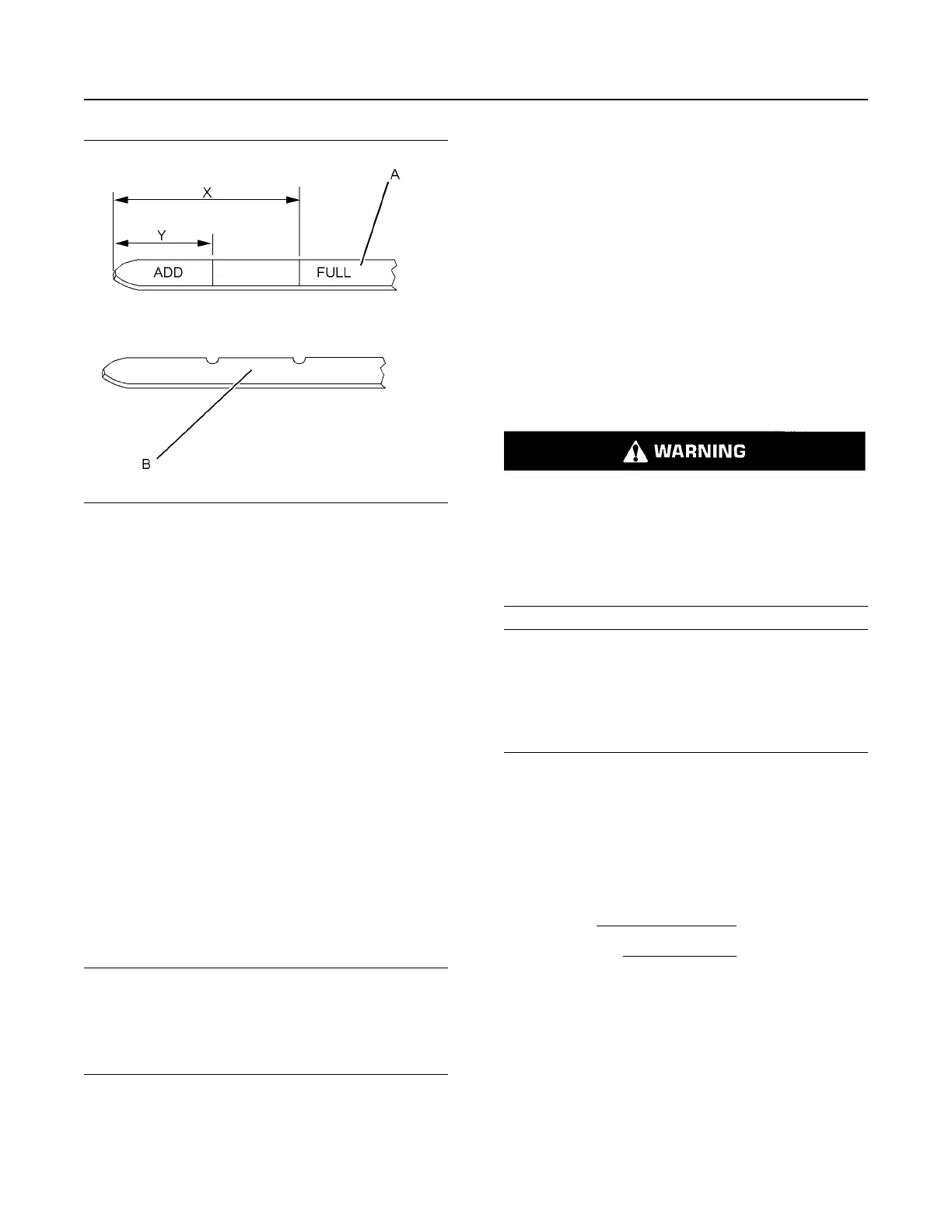

Illustration 63 g03306420

(Y) “ADD” mark. (X) “FULL” mark.

(A) Original oil level gauge

(B) Alternative oil level gauge

4. Remove the oil level gauge to check the oil level.

Maintain the oil level between the “ADD” and

“FULL” marks on the oil level gauge.

i06225025

Engine Protective Devices -

Check

Visual Inspection

Visually check the condition of all gauges, sensors,

and wiring. Look for wiring and components that are

loose, broken, or damaged. Damaged wiring or

components should be repaired or replaced

immediately.

Calibration Check

NOTICE

During testing, abnormal operating conditions must

be simulated.

The tests must be performed correctly in order to pre-

vent possible damage to the engine.

Alarms and shutoffs must function correctly. Alarms

provide timely warning to the operator. Shutoffs help

to prevent damage to the engine. Determination of

the good working order of the engine protective

devices is impossible during normal operation.

Malfunctions must be simulated in order to test the

engine protective devices. To prevent damage to the

engine, only authorized service personnel or your

Perkins distributor should perform the tests.

Consult your Perkins distributor or refer to the

Service Manual for more information.

i06299296

Engine Valve Lash - Check

Ensure that the engine cannot be started while

this maintenance is being performed. To help pre-

vent possible injury, do not use the starting motor

to turn the flywheel.

Hot engine components can cause burns. Allow

additional time for the engine to cool before

measuring/adjusting valve lash clearance.

NOTICE

Only qualified service personnel should perform this

maintenance.

Operation of the engines with incorrect valve lash

can reduce engine efficiency, and also reduce engine

component life.

This maintenance is recommended as part of a

lubrication and preventive maintenance schedule in

order to help provide maximum engine life. The

maintenance for the valve lash is important in order

to keep the engine compliant.

Ensure that the engine is stopped before measuring

the valve lash. The engine valve lash can be

inspected and adjusted when the engine is cold.

• Inlet valve 0.20 mm (0.8 inch)

• Exhaust valve 0.20 mm (0.8 inch)

Refer to Systems Operation, Testing and Adjusting,

“Engine Valve Lash - Inspect/Adjust” for the correct

sequence of adjustment.

96 M0132847

Maintenance Section

Engine Protective Devices - Check

Loading...

Loading...