Locate and Connect the Diverter Valve

The diverter valve is designed to accept full system flow, continuously divert a portion of that flow to the

lifter(s), and pass the remaining flow on to the packer control valve. The amount of flow that is diverted

is adjustable, so the same valve that feeds one lifter can also be adjusted to feed two lifters.

Adding the Perkins diverter valve to your system will slow down your packer cycle by several seconds,

whether you are actively using the lifters or not. However, this is usually an acceptable tradeoff, since

the Perkins diverter valve doesn’t generate much backpressure or heat, and it allows you to use the

packer and the lifters simultaneously.

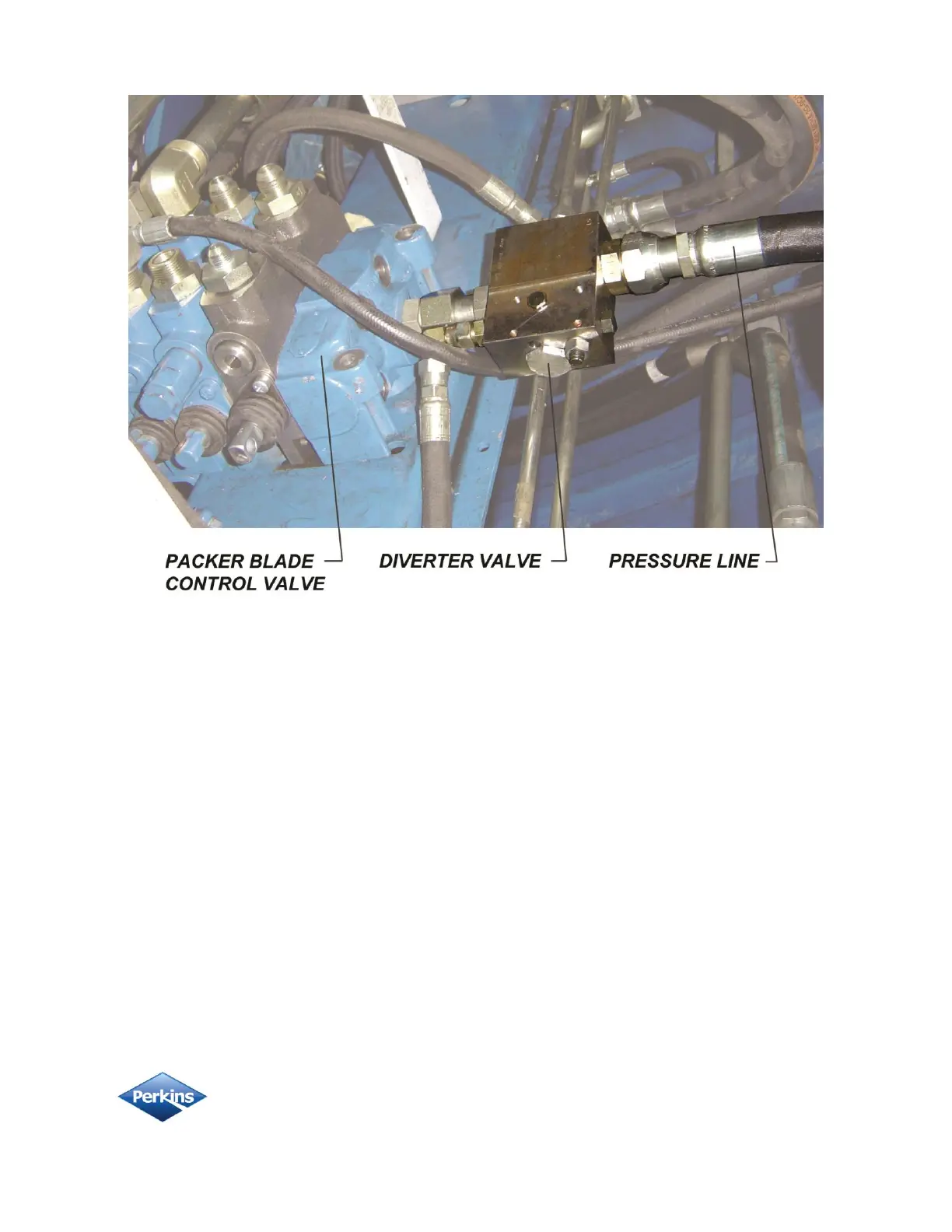

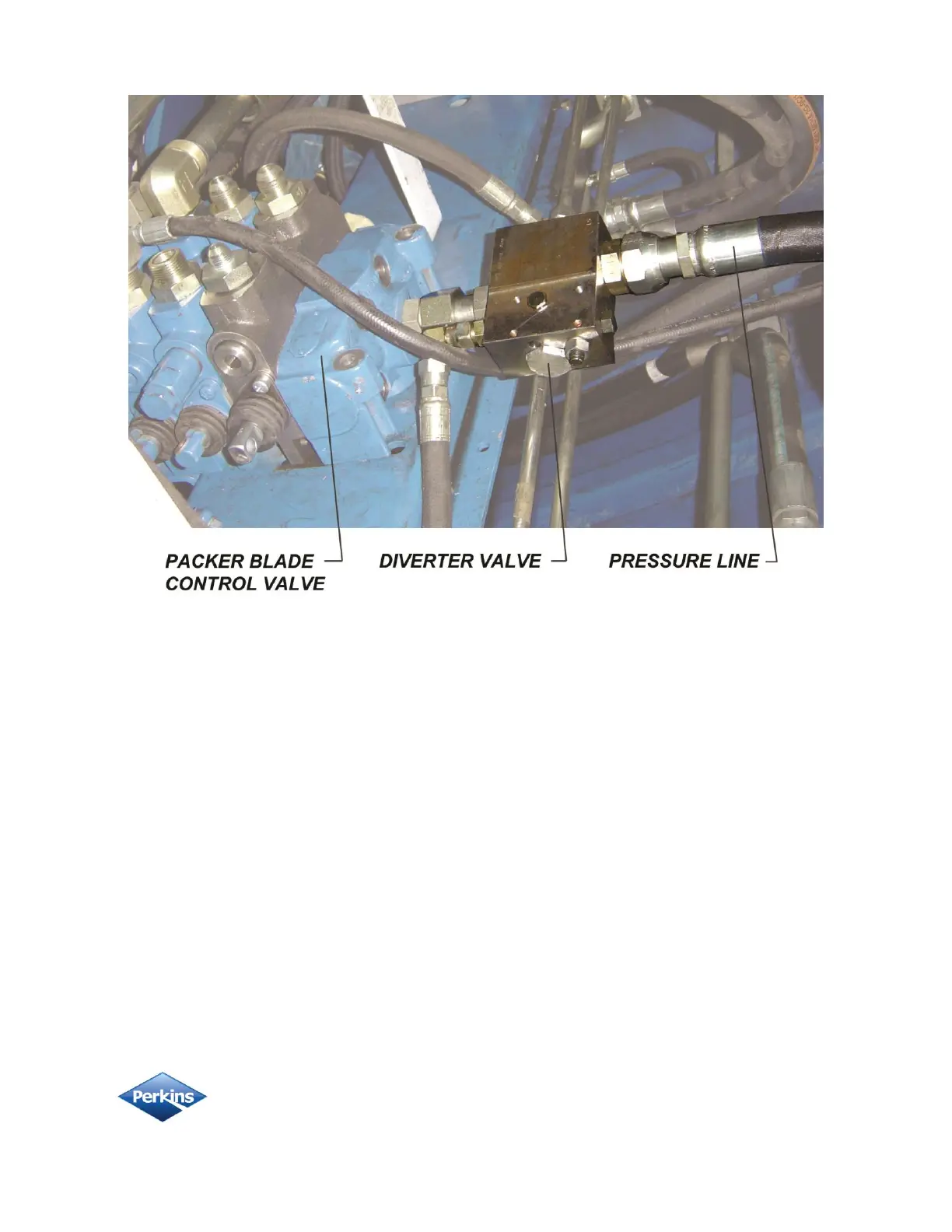

With the system off and depressurized, find the pressure line that feeds the packer valve and disconnect

it. Connect this pressure line to the “IN” port of the Perkins diverter valve. Connect the “OUT” port of

the diverter valve back to the packer control valve where the pressure line originally was.

The fittings to do this will vary from truck to truck. The Perkins Tap-in Kit generally gives you the

required fittings, but due to the wide variety of trucks, changes made by the OEM, as well as the

possibility of other aftermarket parts, especially on used trucks, the fittings you need to make these

connections may not be included in your kit and will have to be purchased separately.

Loading...

Loading...