TB 100

PAG. 18 Cod. 29050055 Rev.01 Edit: 09/2015

6.1 Lubrication points (see 6.14)

Machine lubrication points

6.1.1 Cutter bearing (remove guard) 1 nipple

6.1.2 Cutter bearing (non-drive end) 1 nipple

6.1.3 Wheel spindles Remove wheel - smear with grease

6.1.4 p.t.o. shaft - both ends 2 nipples

6.1.5 Gearbox Check oil level and top-up, as required

Note. Do not overgrease the bearings, as damage to seals may occur.

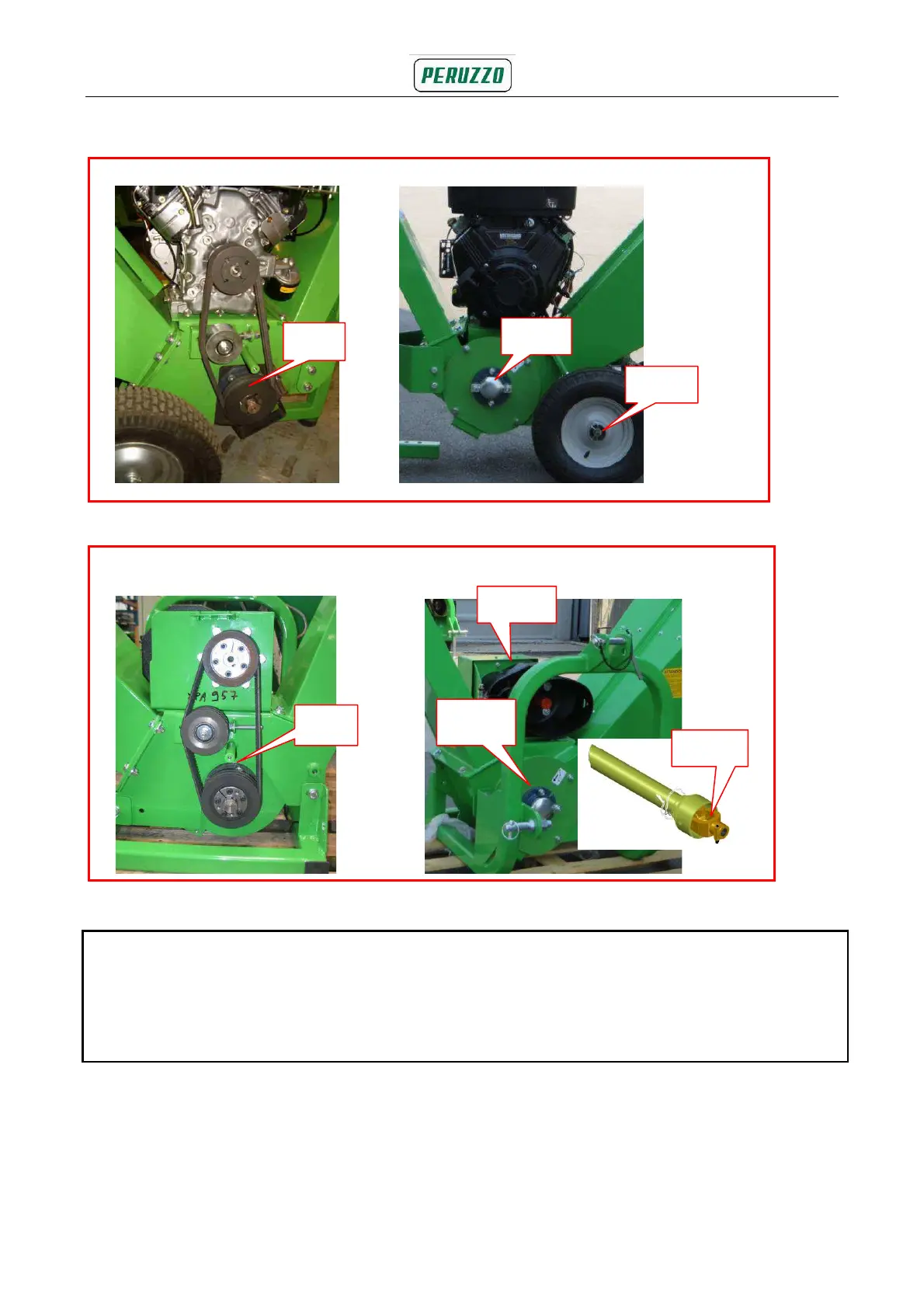

Fig. 6.1b Lubrification points - tractor driven version; hydraulic engine version

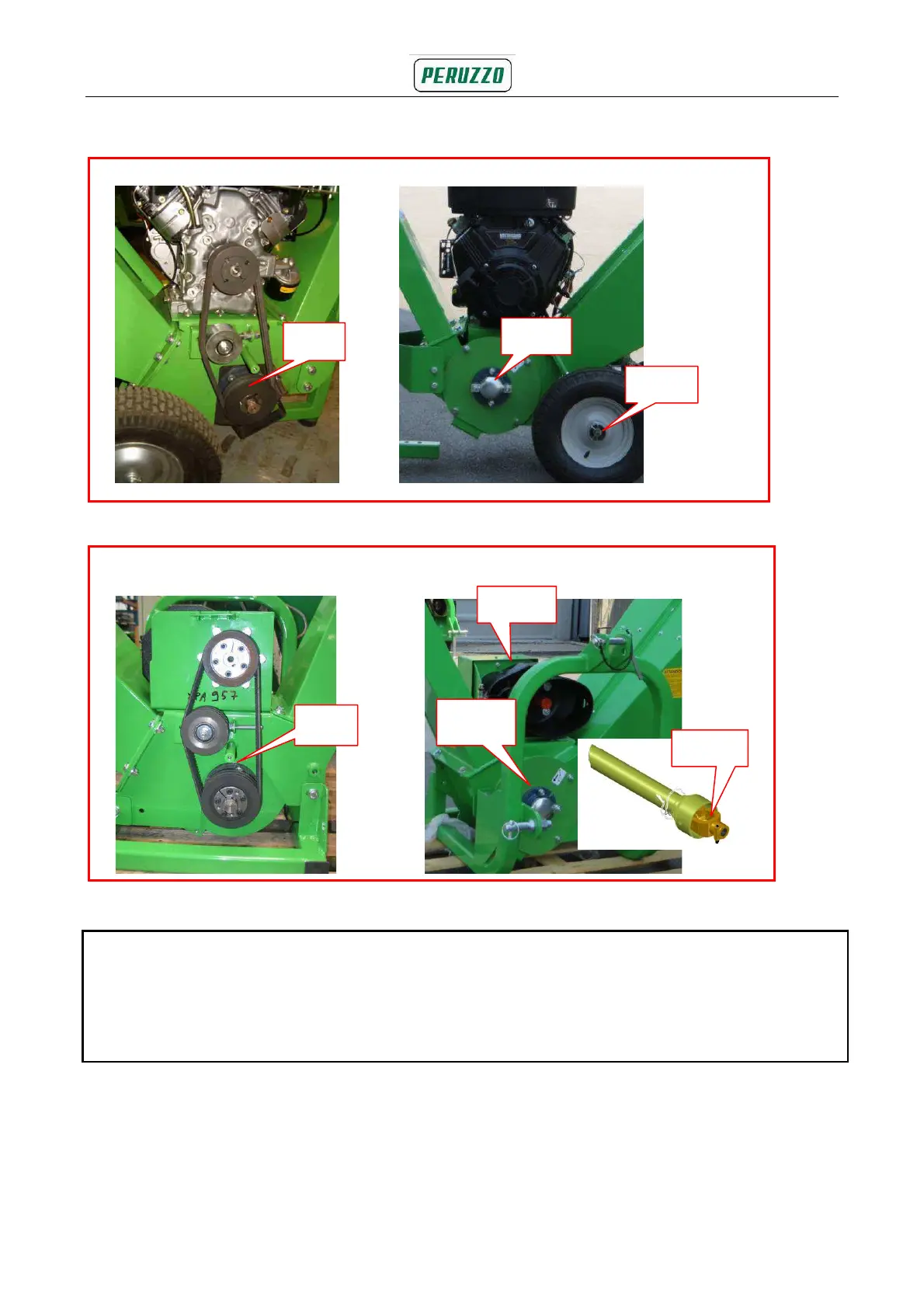

Fig. 6.1a Lubrication points - petrol engine version

6.1.1

6.1.2

6.1.4

6.1.5

6.1.1

6.1.2

6.1.3

Loading...

Loading...