Caliper Detail

1. Brake Caliper Assembly

2.

Location of Inspection Grooves

3. Notches Line-Up (Time to

schedule inspection of Pads and

Rotors)

4. Brake Rotor

5. Brake Carrier Assembly

Regularly inspect caliper for Running

Clearance:

•

Stop the vehicle on level ground

and let the brakes cool down. Hot

brake calipers can burn skin on

contact.

• Chock the wheels.

• Temporarily release the parking

brakes.

•

Grab the caliper and move it. This

movement is Running Clearance.

• Proper Running Clearance is 0.08

inch (2 mm) of movement of the

brake caliper (approximately the

thickness of a nickel) in the

inboard/outboard direction.

• Have a qualified mechanic provide

further inspection if the caliper

does not move or appears to move

more than the specified clearance.

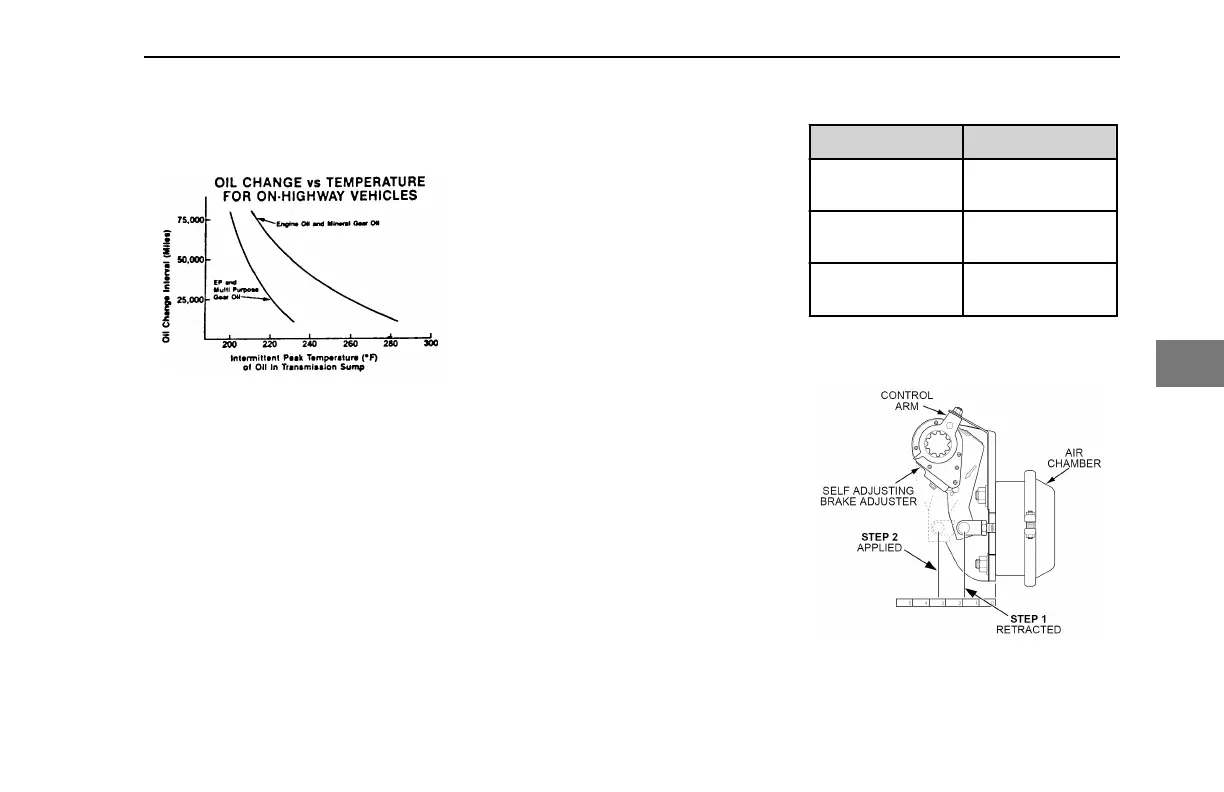

Operational Checks of Automatic

Slack Adjusters

• Measure brake chamber stroke

with the spring brake released and

the air pressure no less than 100

psi (690 kPa).

• Brake Chamber Stroke is the

difference between the applied and

the retracted position of the air

chamber pushrod.

• A correctly installed and functioning

auto slack adjuster will produce the

following strokes:

Chamber Type Stroke

36 (rear brakes) 1-1/2" - 2-1/4" (38 -

57 mm)

30 (rear brakes) 1-1/2" - 2" (38 - 51

mm)

16, 20 & 24 (front

brakes)

1" - 1-3/4" (25.4 -

44.4 mm)

Brake Chamber Stroke

MAINTENANCE - Brake System

Y53-6113-1A1 (11/20) 213

5

Loading...

Loading...