26

5. Adjustment of synchronizer

Note:

The following machine positions or functions are controlled by the synchronizer:

1. A change of feeding direction

2. Sideways needle bar movement

3. Take-up lever/needle "up" positioning

4. Needle "down" positioning

This adjustment must only be carried out when compelling reasons exist! It must be performed

with maximum accuracy.

Requirement:

A change of feeding direction or stitch length must take place when the feed dog has moved below the

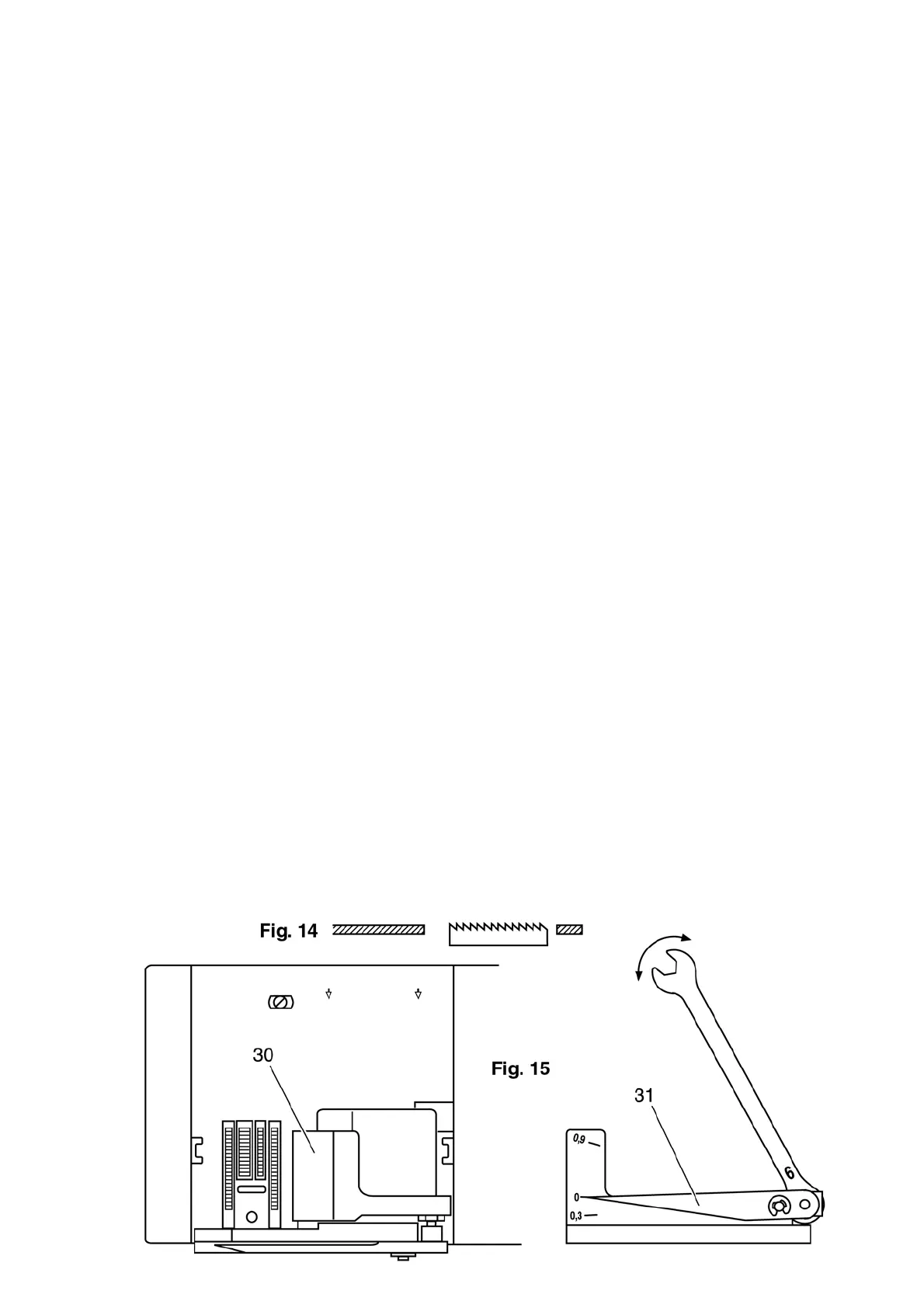

needle plate surface by 0.3 ± 0.02 mm (fig. 14).

Check:

● Remove the needle.

● Remove the presser foot.

● Switch on the master switch.

● Set stitch pattern "01" and stitch length to approx. 0.5 mm.

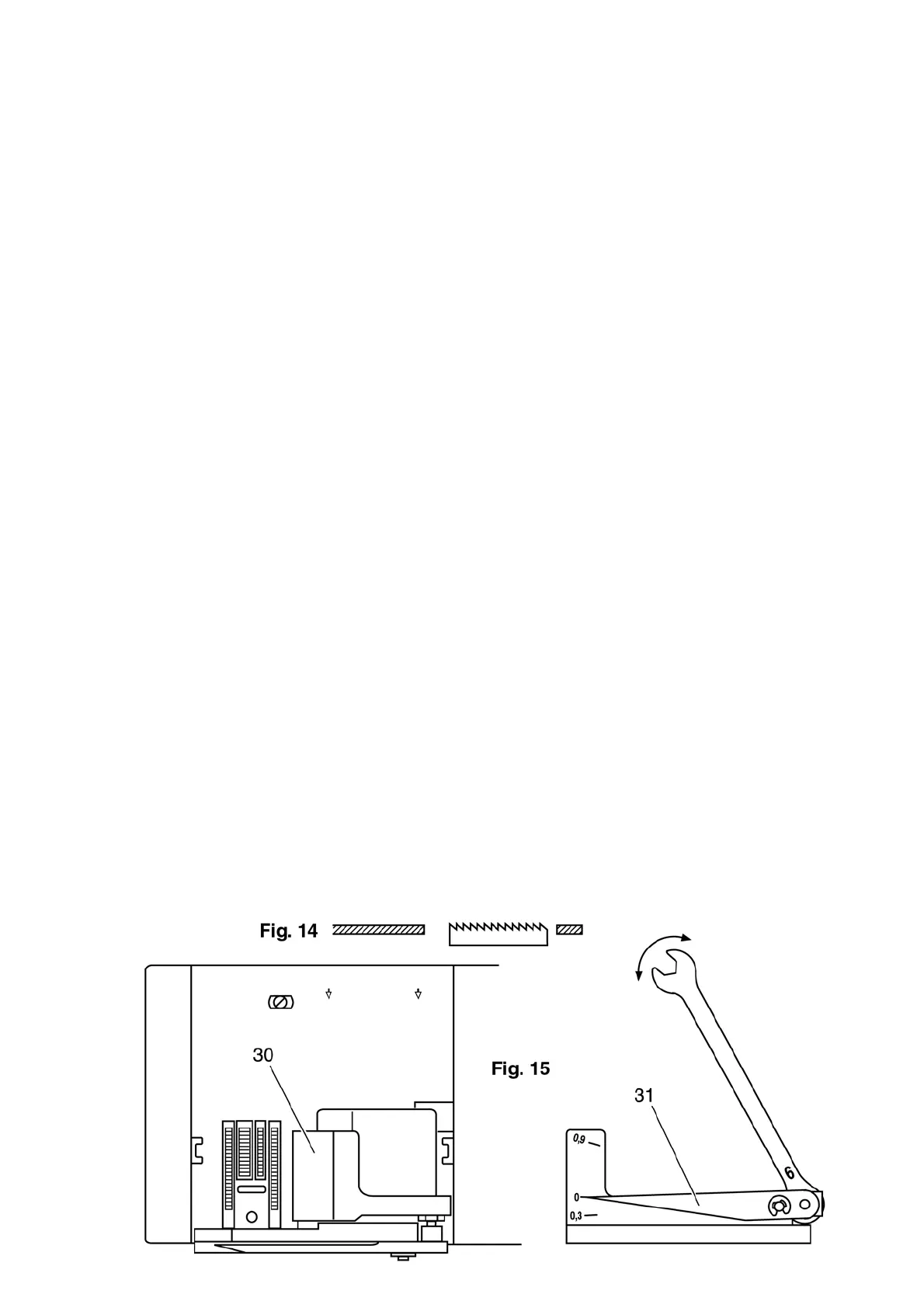

● Set adjustment gauge (63-114 690-23) on the needle plate so that feeler lever 30 rests on the needle

plate just right of the feed slots (fig. 15).

● Turn the hexagon with a 6 mm spanner (wrench) until pointer 31 is exactly at "0".

● Turn the handwheel a full rotation forwards, then keep on turning it until the feed dog (needle bar)

is in its top position.

● Change the stitch length.

● Set the adjustment gauge with feeler lever 30 to the left on the feed dog (fig. 32).

● Turn the handwheel very slowly forwards until pointer 30 is at 0.3 (fig. 33). In this position the feed

dog must make a visible and audible (switching) movement.

Loading...

Loading...