62

Fitting:

● Lift complete hook driving shaft 28 out of the lower right calotte bearing 92 as far as it will go (fig. 78).

● Pull the flat toothed belt between calotte 95 and calotte bearing 92.

● Place hook driving shaft 28 together with calotte 95 in the lower right calotte bearing 92 exactly.

● Fit clamping plate 91 and fasten with screw 90.

● Pull flat-toothed belt 98, which is in the inner housing, upwards.

● Feed arm shaft 106 from the right into the housing (fig. 77).

● Place flat-toothed belt 98 over arm shaft 106.

● Feed arm shaft 106 into needle bar crank 101.

● Insert arm shaft 106 into calotte bearings 104 and 105.

● Fit clamping plates 103 and fasten with screws 102.

● Check for free movement of arm shaft, if necessary establish the free movement.

● Place flat-toothed belt 98 onto the upper and lower sprockets 93 and 94.

● Set the flat-toothed belt's tension according to section 1.

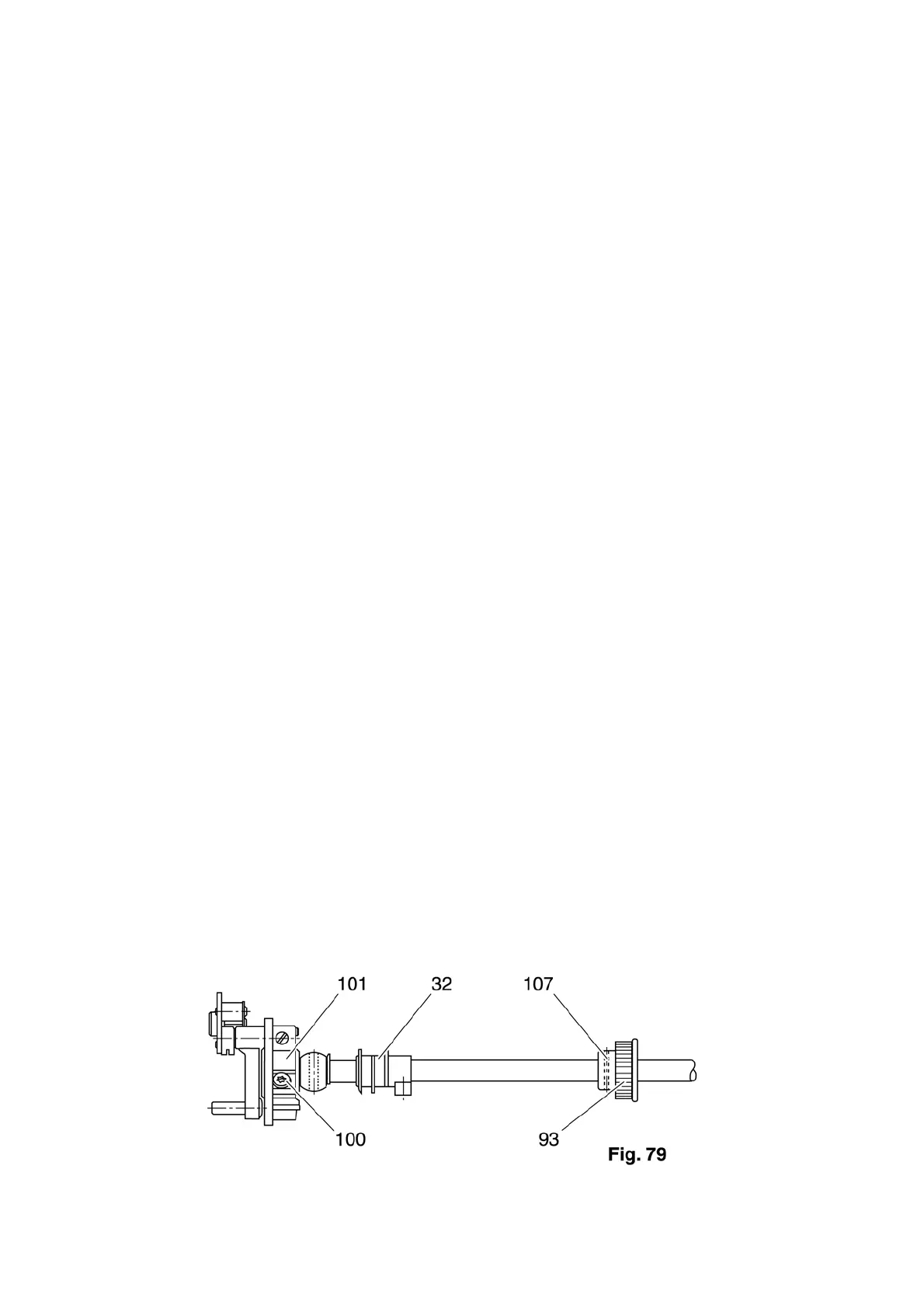

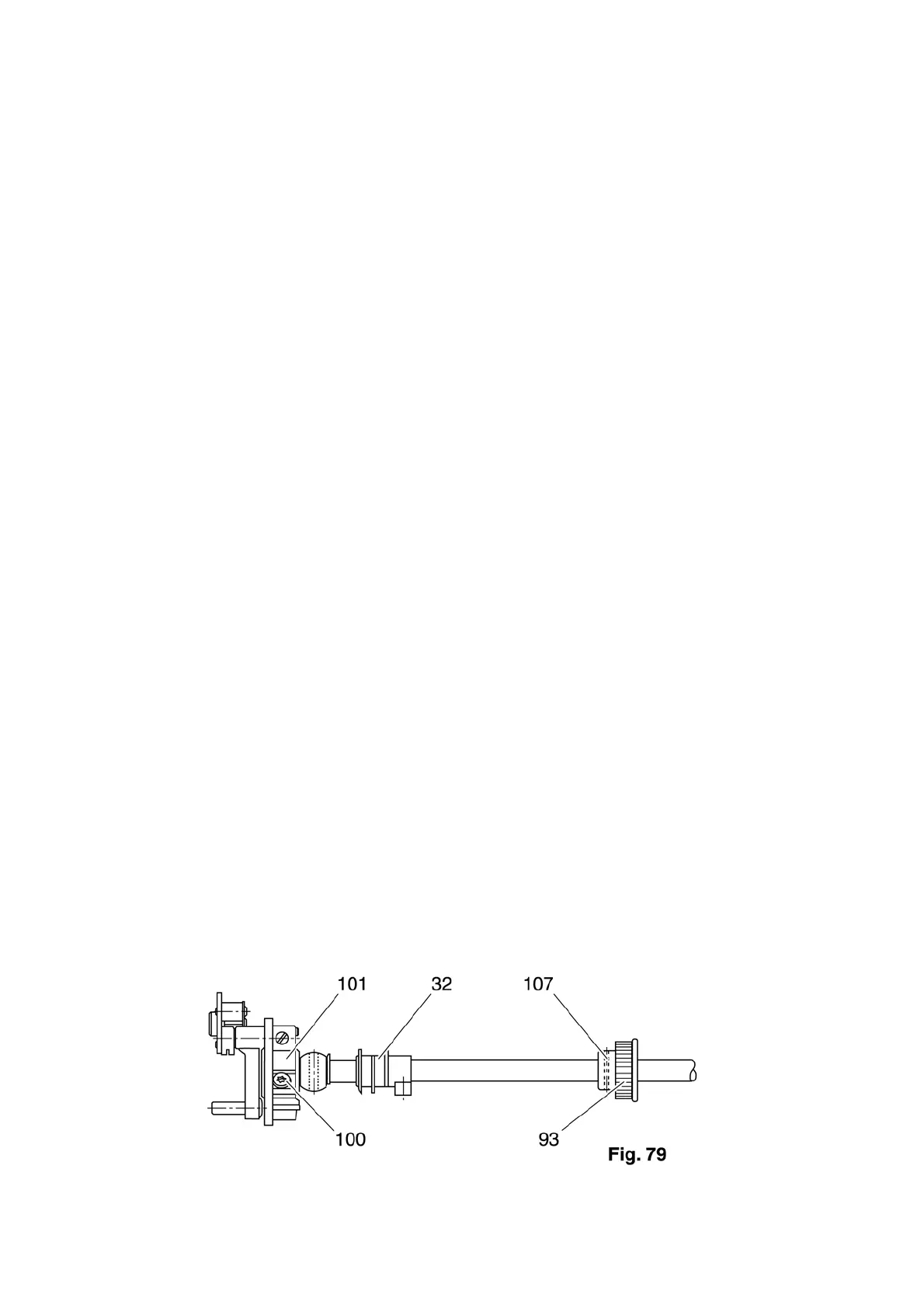

● Turn the handwheel until the fastening screw of the synchronizer control cam 32 faces downwards

(fig. 79).

● At the same time pin 107 on the upper sprocket faces upwards.

● Press needle bar crank 101 against the calotte of the left calotte bearing 104. At the same time tighten

screw 100 on needle bar crank 101.

● Check for free movement of the arm shaft, if necessary establish it.

● Attach connecting rod 99 (fig. 77).

● Mount lockwasher 51 onto the needle bar frame.

● Attach pull-spring 96.

● Attach circlip 97 to the zigzag stepping motor.

● Attach connection plugs 7, 12, 13, 14, 15 and 16 to the circuit board on the front housing shell.

● Mount the front housing shell and fasten with torx screws 17, 18 and 19.

● Mount the rear housing shell and fasten with torx screws 10 and 11.

● Mount the stand cover and fasten with torx screws 5.

● Attach the needle plate.

● Attach connection plugs 3 and 4 to the circuit board on the baseplate.

● Locate the baseplate, the freearm lid with bobbin thread monitor and the buttonhole sensor to the right

next to the machine.

Loading...

Loading...