3)7*67$1'$5' 86$

6HWWLQJV

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

________________________________________________________________________________________

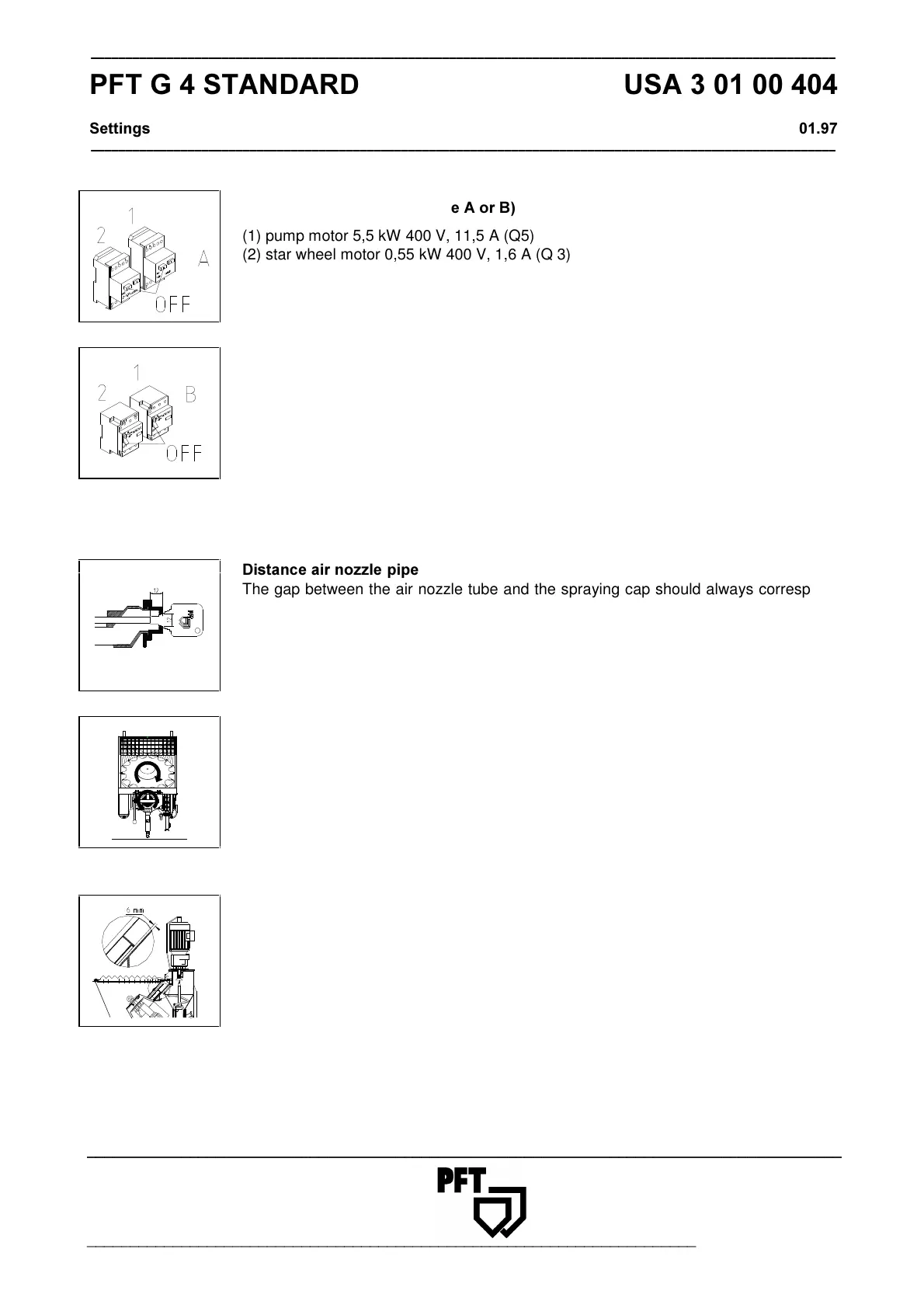

0RWRUSURWHFWLRQVZLWFKW\SH$RU%

(1) pump motor 5,5 kW 400 V, 11,5 A (Q5)

(2) star wheel motor 0,55 kW 400 V, 1,6 A (Q 3)

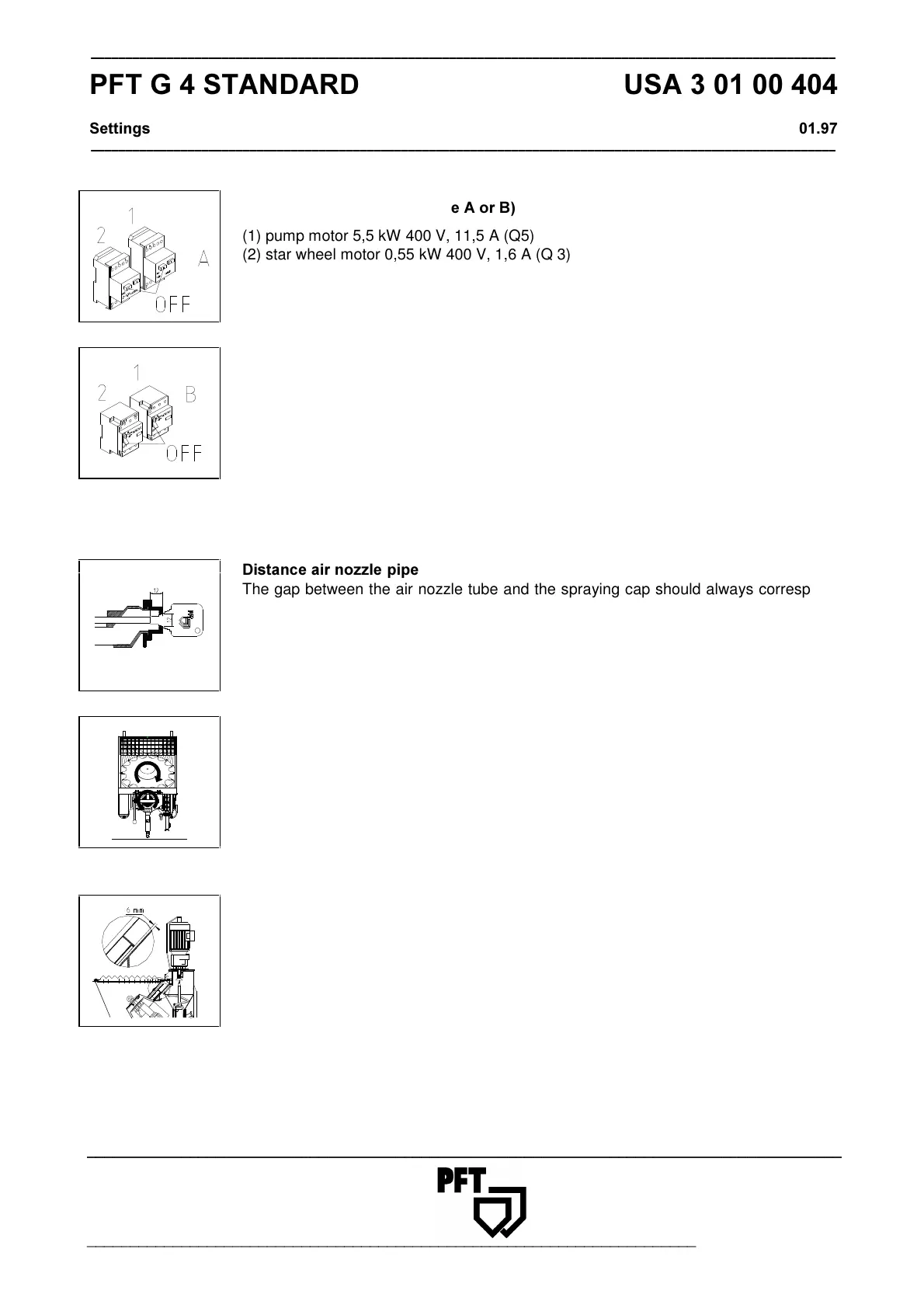

'LVWDQFHDLUQR]]OHSLSH

The gap between the air nozzle tube and the spraying cap should always correspond

the hole diameter of the spraying cap;

e.g. 15 mm spraying cap = 14 mm gap.

'LUHFWLRQRIURWDWLRQRISXPSPRWRU

When the motor stars up, it is essential that the ventilator wheel should be observed; it

must turn in an anti-clockwise direction.

'LUHFWLRQRIURWDWLRQRIVWDUZKHHOPRWRU

The star wheel normally works independently of the direction of rotation. When using a

SILOMAT conveying system, we recommend clockwise rotation (factory setting). In

the case, it is also assured that the pump motor will turn in the right direction.

6WDUZKHHO

Distance from star wheel to hopper base: factory setting approx. 6 mm.

Rule of thumb:

1,5 x diameter of the largest grain of the dry mortar. If necessary, a star wheel

distance disk (art. no. 20 10 19 00) for course plaster can be fitted.

Loading...

Loading...