146

3.3.10.

Soldering

micro-miniature

semi-conductors

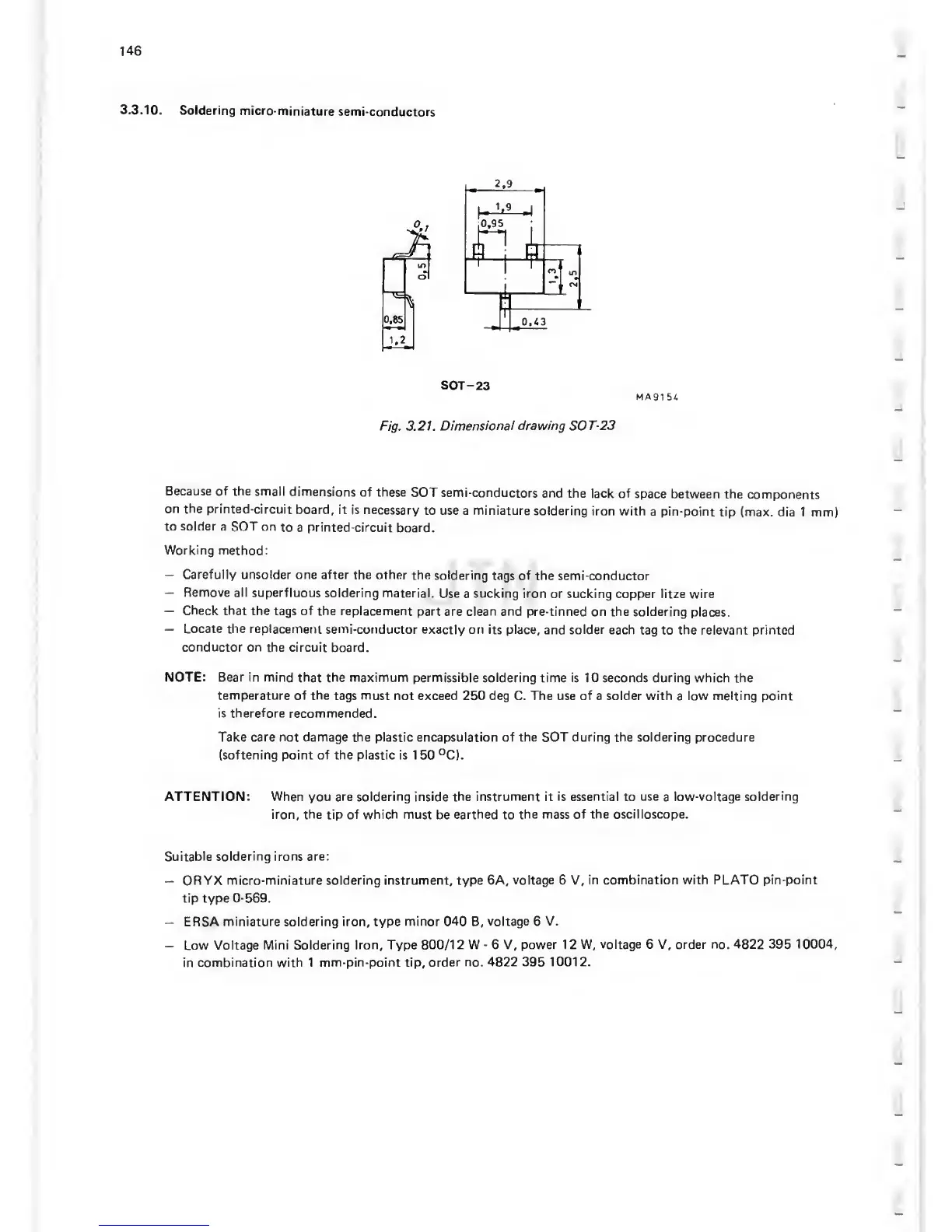

SOT

-23

MA91

54

Fig. 3.21.

Dimensional drawing SOT-23

Because of the

small

dimensions

of these

SOT semi-conductors

and

the

lack of

space

between the

components

on the

printed-circuit

board, it is

necessary

to use a miniature

soldering

iron with

a pin-point

tip (max. dia

1 mm)

to solder

a SOT on

to

a

printed-circuit

board.

Working

method;

—

Carefully unsolder one after the other

the

soldering

tags of the semi-conductor

—

Remove ail superfluous

soldering material.

Use a

sucking

iron or

sucking copper litze wire

—

Check that

the tags of the replacement

part are clean and

pre-tinned on the soldering

places.

—

Locate the replacement

semi-conductor

exactly on its place, and solder

each

tag to

the

relevant printed

conductor

on the circuit board.

NOTE: Bear in mind

that the maximum permissible soldering time

is 10 seconds during which the

temperature of the

tags

must

not exceed 250 deg C. The use of a solder with a low melting point

is therefore recommended.

Take care not damage

the

plastic encapsulation of the SOT during the soldering procedure

(softening

point of the plastic is 1

50

°C).

ATTENTION:

When you are soldering inside the

instrument

it is

essential

to

use

a

low-voltage soldering

iron, the tip of which must be earthed to

the mass of the oscilloscope.

Suitable

soldering irons are;

—

ORYX micro-miniature

soldering instrument,

type 6A,

voltage 6 V,

in combination with PLATO pin-point

tip type

0-569.

—

ERSA

miniature soldering iron,

type

minor 040 B,

voltage 6 V.

—

Low

Voltage Mini Soldering

Iron, Type 800/12 W

-

6 V,

power

12

W, voltage 6 V, order no. 4822

395

10004,

in combination with 1

mm-pin-point tip, order no.

4822

395

10012.

Loading...

Loading...