CP600 Pivot Operators Manual

OPERATION, SAFETY & MAINTENANCE

Section 1-12

© Pierce Corporation

July 2010

Note: The following maintenance procedures must be performed or the drivetrain

warranty will be void.

The fi nal drive wheel gearbox, center drive gear motor and the worm gear center drive require pre-

season maintenance. Please refer to the following service information for the above items.

If you should have any questions, please call your Pierce Dealer or Customer Service Representa-

tive.

FINAL DRIVE GEARBOX MAINTENANCE PROCEDURES

A. The fi nal drive gearbox must be serviced as follows after each crop cycle:

1. Inspect input and output shaft seals for leakage. Should either the input or out

put shaft show excessive leakage, the seals should be replaced. All replaced

seals must be installed with generous amounts of #2 Barium/Lithium based grease

or use equivalent quality #2 water-resistant grease.

2. External (dust exclusion) seals should be used to keep dirt and water out of inter-

nal seal locations. If the external seals are damaged or worn, replace with new

seals.

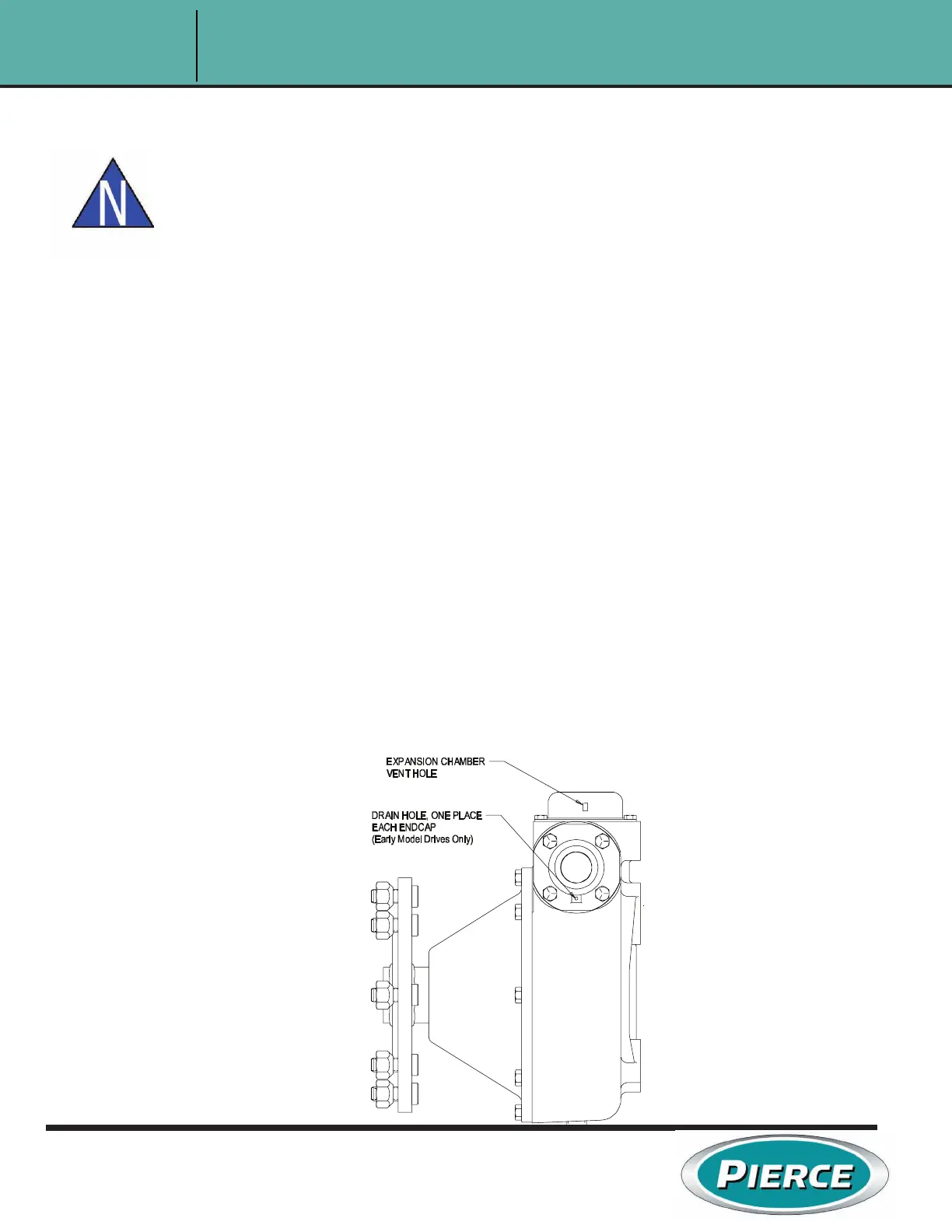

3. The seal drain hole located on both input caps must be kept clear of dirt. Clear the hole

with a 12-gauge wire, nail or punch. Rotate the tool to loosen and remove dirt. Make sure the

vent hole in the expansion chamber is free of dirt or debris.

Power Drivetrain Maintenance

Power Drivetrain Maintenance

Figure 1-10.

File: ams_srvc_0199.doc

Copyright 08/2004

I - FINAL DRIVE GEARBOX MAINTENANCE PROCEDURES

A. THE FINAL DRIVE GEARBOX MUST BE SERVICED AS FOLLOWS AFTER EACH CROP

CYCLE, A MINIMUM OF ONCE A YEAR.

SEE SECTION “

V

” “TOW HUB MAINTENANCE” FOR 725-UT TOWABLE

GEARBOXES.

SEE SECTION “D” AND “E”

FOR ADDITIONAL REQUIREMENTS FOR TNT AND 760

MODELS.

1. Inspect input and output shaft seals for leakage. Should either the input or output shaft seals show

excessive leakage, the seals should be replaced. All replaced seals must be installed with

generous amounts of #2 Barium/Lithium base grease (or use equivalent quality #2 water resistant

grease) on the seal lips.

2. External (dust exclusion) seals should be used to keep dirt and water out of internal seal locations.

If the external seals are damaged or worn, replace with new seals. Note that there are several

different types of seals available.

3. The seal drain hole (on 720 and previous models and on 725 units shipped before October

1996) located on both input caps must be kept clear of dirt. Clear the hole using a 12-gauge wire,

a nail or a punch. Lightly rotate the tool to loosen and remove dirt. CAUTION, DO NOT DAMAGE

THE SEAL CASE OR LIPS. See Diagram FD-1.

4. The vent hole located on the side of the Expansion Chamber must be kept clear of dirt. Use a soft

brush to clear the opening. DO NOT INSERT ANY OBJECTS INTO THE VENT HOLE,

DAMAGE TO THE RUBBER DIAPHRAGM MAY OCCUR.

DIAGRAM FD-1

Loading...

Loading...