10/24

5.4 Replacement of the actuator

Attention:The machine manufacturer must restrict access to the sensor

programming mode to authorised personnel only.

Via input I3 it is always possible to replace the coded actuator with a second actuator

at any time. By activating this input the device sets to the programming mode and the

IN LED flashes orange; it disables all OS1, OS2, O3, O4 outputs and releases the

actuator. With the input enabled, insert the second actuator. Acquisition of the second

actuator is confirmed by the IN LED switching off and by four flashes of the ACT LED.

At this point the I3 input can be disabled. The device will automatically set to restart

and the first actuator will no longer be recognised.

The second actuator must be suitably fixed to the guard as described in paragraph

INSTALLATION INSTRUCTIONS.

This operation must not be carried out as a repair or maintenance operation. If

the device ceases to function correctly, replace the entire device and not just the

actuator.

5.5 Reset input

The following error states due to a failure external to the device can be rest using the

I3 input:

- a short circuit or overcharge of safety outputs (OS1, OS2),

- a short circuit between a safety output and the supply voltage,

- an excessive misalignment between the device and the locked actuator.

5.6 Connection in series with safety modules

It is possible to install multiple cascade-connected devices, up to a maximum of 32

units, whilst maintaining safety category 4 / PL e according to EN ISO 13849-1 and

integrity level SIL CL 3 according to EN 62061.

Check that the PFH

d

value and MTTF

d

value of the system consisting of the cascade

of devices and the entire safety circuit meet the requirements of the SIL/PL level

requested by the application.

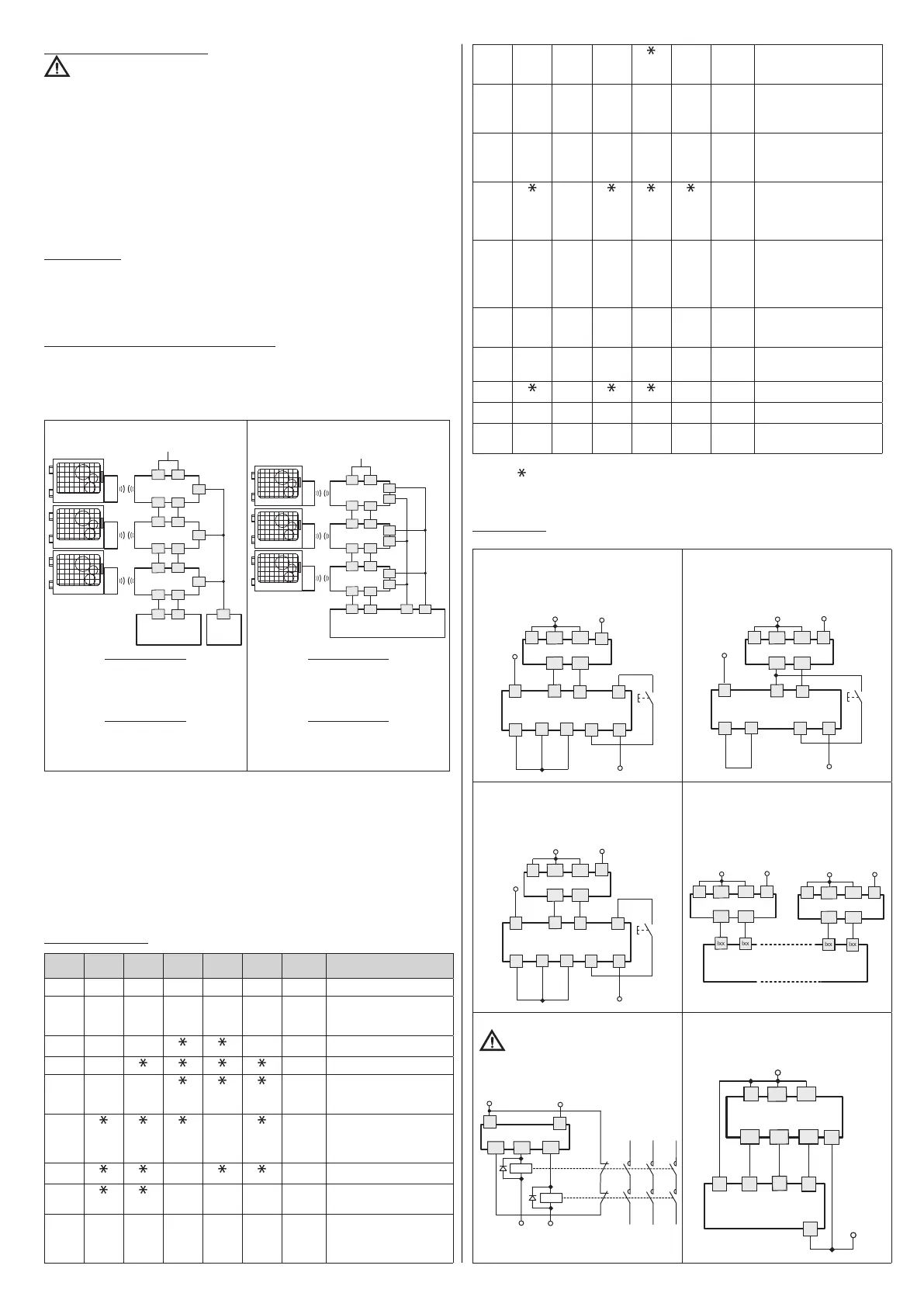

Application example with single channel

locking control function

Application example with dual channel

locking control function

NG

NG

NG

CS

CS AM

CS FS

OS1 OS2

IS1 IS2

IS1 IS2

OS1 OS2

IS1 IS2

OS1 OS2

Ixx Ixx Ox

I4

VN NG-F3•

VN NG-F3•

VN NG-F3•

+ Vcc

I4

I4

NG

NG

NG

OS1 OS2

IS1 IS2

IS1 IS2

OS1 OS2

IS1 IS2

OS1 OS2

OS1 OS2

VN NG-F3•

VN NG-F3•

VN NG-F3•

+ Vcc

CS MP

Ixx Ixx

IE1

IE2

IE1

IE2

IE1

IE2

Device with mode 1

Lock detection function (guard locked): 2

channels / Category 4 / up to SIL 3 / PL e

Locking control function:

1 channel / Category 2 / up to SIL 2 / PL d

Device with mode 1

Lock detection function (guard locked): 2

channels / Category 4 / up to SIL 3 / PL e

Locking control function:

2 channels / Category 4 / up to SIL 3 / PL e

Device with mode 2

Interlock detection function (guard closed): 2

channels / Category 4 / up to SIL 3 / PL e

Locking control function:

1 channel / Category 2 / up to SIL 2 / PL d

Device with mode 2

Interlock detection function (guard closed): 2

channels / Category 4 / up to SIL 3 / PL e

Locking control function:

2 channels / Category 4 / up to SIL 3 / PL e

When connecting the devices in series as described above, observe the following:

- Connect the inputs of the first device in the chain to the supply voltage.

- The OS1 and OS2 safety outputs of the last device in the chain must be connected

to the safety circuit of the machine.

- Where a safety module is used, check that the properties of safety outputs OS1/

OS2 are compatible with the safety module inputs (see paragraph INTERFACING).

- Respect the stray capacitance limits on the output lines indicated in the electrical

data (see paragraph TECHNICAL DATA).

- Check that the response time of the cascade meets the requirements of the safety

function to be implemented.

- The activation time of the cascade must be calculated taking into account the re-

sponse time of every single device.

5.7 Operating states

PWR

LED

IN

LED

OUT

LED

ACT

LED

LOCK

LED

EDM

a

Device

state

Description

O O O O O O OFF Device switched off.

green

/ red,

alter-

nating

green

/ red,

alter-

nating

green

/ red,

alter-

nating

green

/ red,

alter-

nating

green

/ red,

alter-

nating

green

/ red,

alter-

nating

POWER

ON

Internal tests upon activation.

green O O

green RUN Safety inputs of the device not

active.

green green

RUN Activation of safety inputs.

green green /

orange,

alterna-

ting

O

RUN Safety inputs incoherence.

Recommended action: check

for presence and/or wiring of

inputs.

green

blinking

red

RUN Incoherence of solenoid acti-

vation inputs IE1, IE2.

Recommended action: check

for presence and/or wiring of

inputs.

green

green RUN Actuator in safe area. O3 si-

gnalling output active.

green

green green O RUN Actuator in safe area and

locked; O3 and O4 outputs

active.

green green green green green O RUN Mode 1

Activation of safety inputs IS1,

IS2. Actuator in safe area and

locked. O3, O4, OS1 and OS2

outputs active.

green green green green O RUN Mode 2

Activation of safety inputs IS1,

IS2. Actuator in safe area. O3,

OS1 and OS2 outputs active.

green orange orange green green O RUN Mode 3.

Actuator present, guard clo-

sed and locked, IS1 enabled,

IS2 disabled, OS1 enabled,

OS2 disabled

green green orange green O O RUN Mode 3.

Actuator present, guard clo-

sed and not locked, IS1 and

IS2 enabled, OS1 disabled,

OS2 enabled

green

red,

alterna-

ting

ERROR Error on safety outputs. Re-

commended action: check for

any short circuits between the

outputs, outputs and ground

or outputs and power supply,

then restart the device.

green O O red,

alterna-

ting

O O ERROR Actuator detection error.

Check the physical integrity of

the device and, in case of fai-

lure, please replace the entire

device. If undamaged, realign

the actuator with the device

and restart the device.

red O O O O O ERROR Internal error. Recommended

action: restart the device. If

the failure persists, replace

the device.

red,

alterna-

ting

O O O O O ERROR Temperature error outside the

permissible range

green

O green RUN EDM signal active (external

relay off)

a

green green green green green O RUN EDM signal not active

(external relay on)

a

green O O O O red,

alterna-

ting

ERROR Error in the EDM

a

function

O = off = indifferent (a) = available only in version NG 2•••5•••

5.8 Interfacing

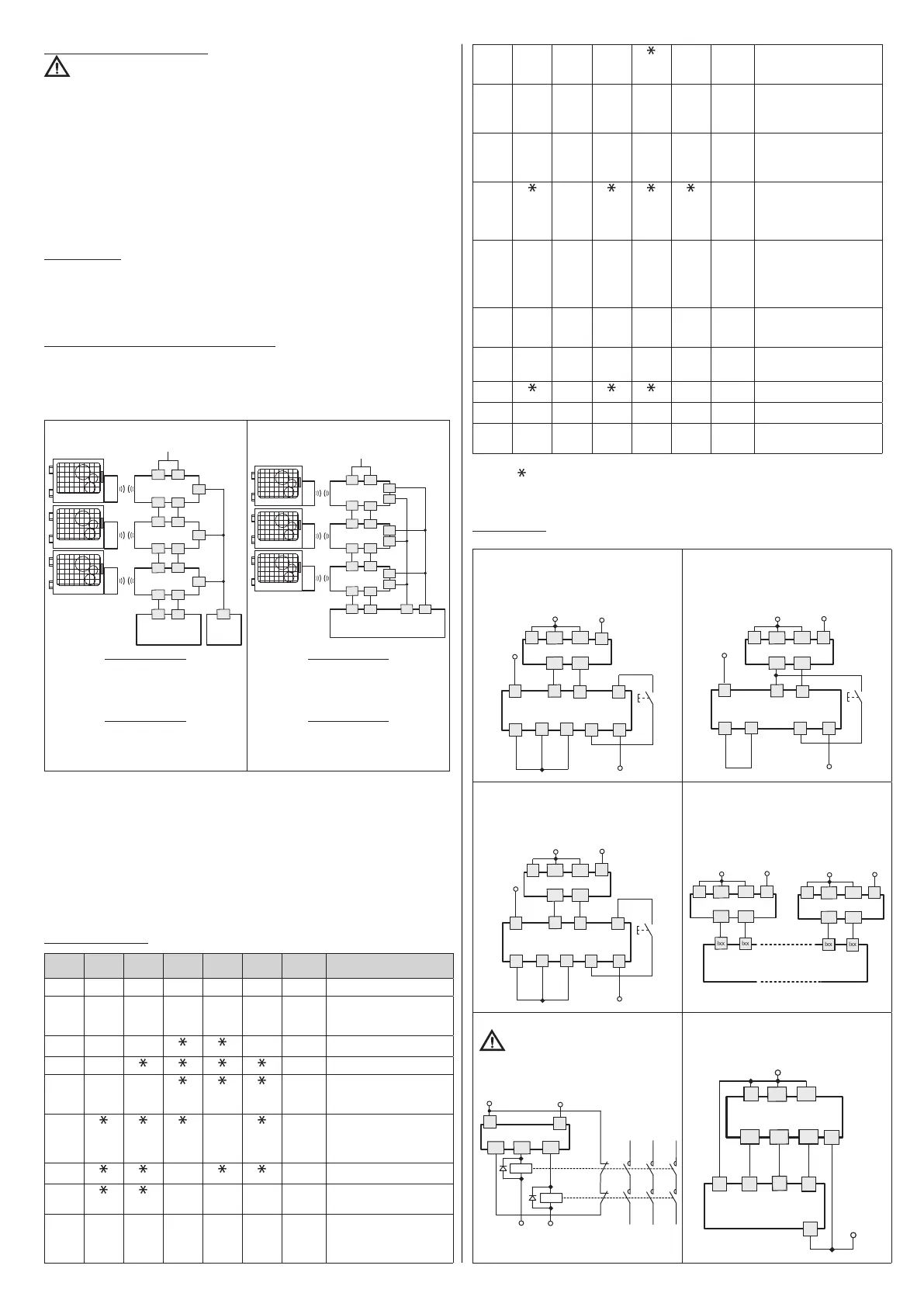

Connections with CS AR-08•••• safety

modules

Input configuration with monitored start

Connections with CS AR-05•••• / CS

AR-06•••• safety modules

Input configuration with manual start (CS

AR-05••••) or monitored start (CS AR-06••••)

S33

S21 S22

S35

S34

A2

S52

S12

A1

-

+

OS2

OS1

IS2

IS1

A1

+

A2

-

NG

CS

S21 S22

S34

A2

A1

-

+

S52

S12

OS2

OS1

IS2

IS1

A1

+

A2

-

NG

CS

Connections with CS AT-0••••• / CS

AT-1••••• safety modules

Input configuration with monitored start

Connections with CS MF••••0, CS

MP••••0 safety modules

The connections vary according to the program

of the module

S33

S21 S22

S35

S34

A2

A1

-

+

S31

S12

OS2

OS1

IS2

IS1

A1

+

A2

-

NG

CS

OS2

OS1

IS2

IS1

A1

+

OS2

OS1

IS2

IS1

A1

+

A2

-

A2

-

NG

NG

CS

EDM connection

Caution: if all OS safety outputs are

connected directly to a safety contactor,

we recommend using fast switching diodes

connected in parallel to the contactor coils.

OS2

OS1

I5

A1

+

A2

-

NG 2•••5•••

KM1

KM2

Connections with expansion module CS

ME-03••••

For NG 2•••5••• devices only

with mode 1 or 2

OS2

OS1

IS2

IS1

A1

+

A2

-

NG

I5

OS2

OS1

EDM EDM

A2

CS

Loading...

Loading...