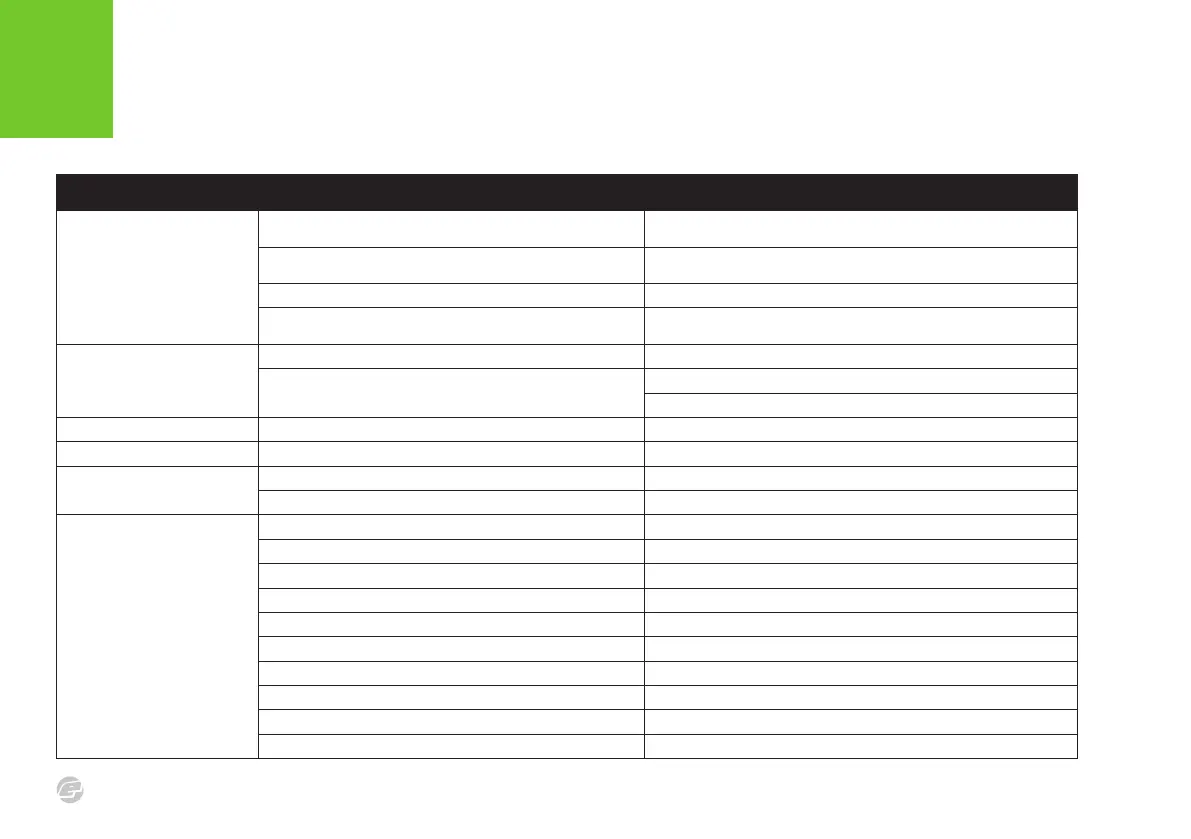

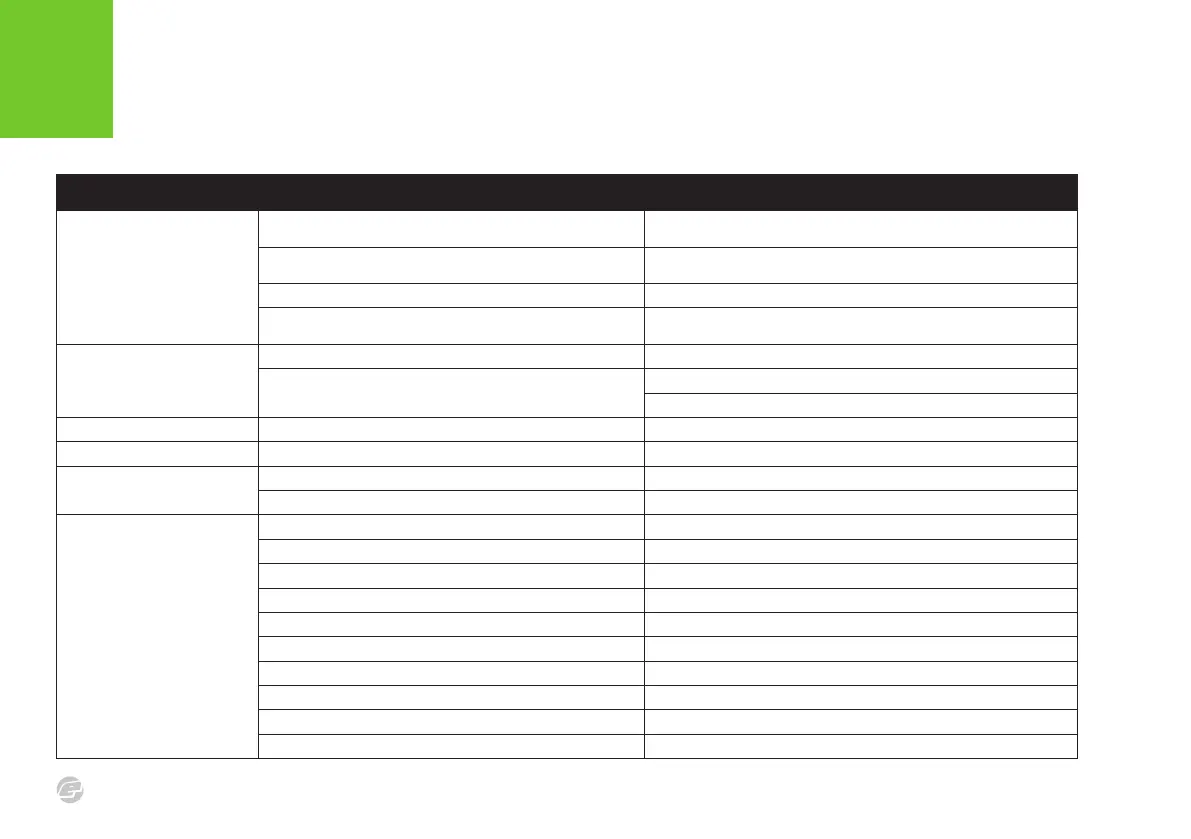

MAINTENANCE

FA ULT FI NDIN G TAB LES

C S 3

30

SYMP TOM POS SIBLE CAUS E SO LU TIO N

The CS3 leaks down the barrel.

Dirty or damaged can o-rings.

Clean and lubricate or replace 020 NBR70 and 017 NBR70 o-rings on the

front of the can.

Dirty or damaged o-rings on the spool.

Clean and lubricate or replace the 011 NBR70 and 012 NBR70 o-rings on

the main spool.

Dirty or damaged bolt o-rings. Clean and lubricate or replace 14x2 NBR70 o-ring on the back of the bolt.

Dirty or damaged rear bolt guide o-ring.

Clean and lubricate or replace 017 NBR70 o-ring on the back

of the bolt guide.

Low rate of re / rate of re not

reaching the ROF cap.

The force setting of the loader is too low. Adjust the loader force feed setting.

The breech sensor has detected a fault and has reduced the ROF.

Check the position and condition of the breech sensors.

Clean the breech sensors as required.

Low constant velocity. The inline regulator output pressure set too low. Increase the output pressure of the inline regulator.

High velocity rst shot. The inline regulator pressure is creeping. Strip and clean the inline regulator replacing the piston seal.

The trigger is very “bouncy”.

Incorrect lter settings. Check that your DEBOUNCE settings suit your trigger set-up.

Trigger pull is too short and the return strength is too low. See page 22 for trigger adjustment guidelines.

The CS3 does not re.

The CS3 is not powered up. Power up the CS3 using the Select button on the navigation console.

The POPS is not fully engaged. Pull the POPS bonnet back until it engages..

The battery quality or charge level is very low. Install new high quality alkaline or lithium batteries.

The batteries are at. Replace the batteries.

The DWELL parameter is set too low. Increase the DWELL parameter.

The trigger is set-up incorrectly. Adjust trigger correctly to fully open and close the microswitch.

The solenoid is not plugged into the CS3 PCB. Plug solenoid wire into its port on the CS3 PCB.

Breech sensor is enabled but no paint is in the breech. Fill the loader with paint. Check for blockages in loader or feedtube.

The main PCB is damaged. Replace the main PCB.

The pilot valve is damaged. Replace the pilot valve.

Loading...

Loading...