Pub. No. OM-A-10H REV. 7 — June 2006 11

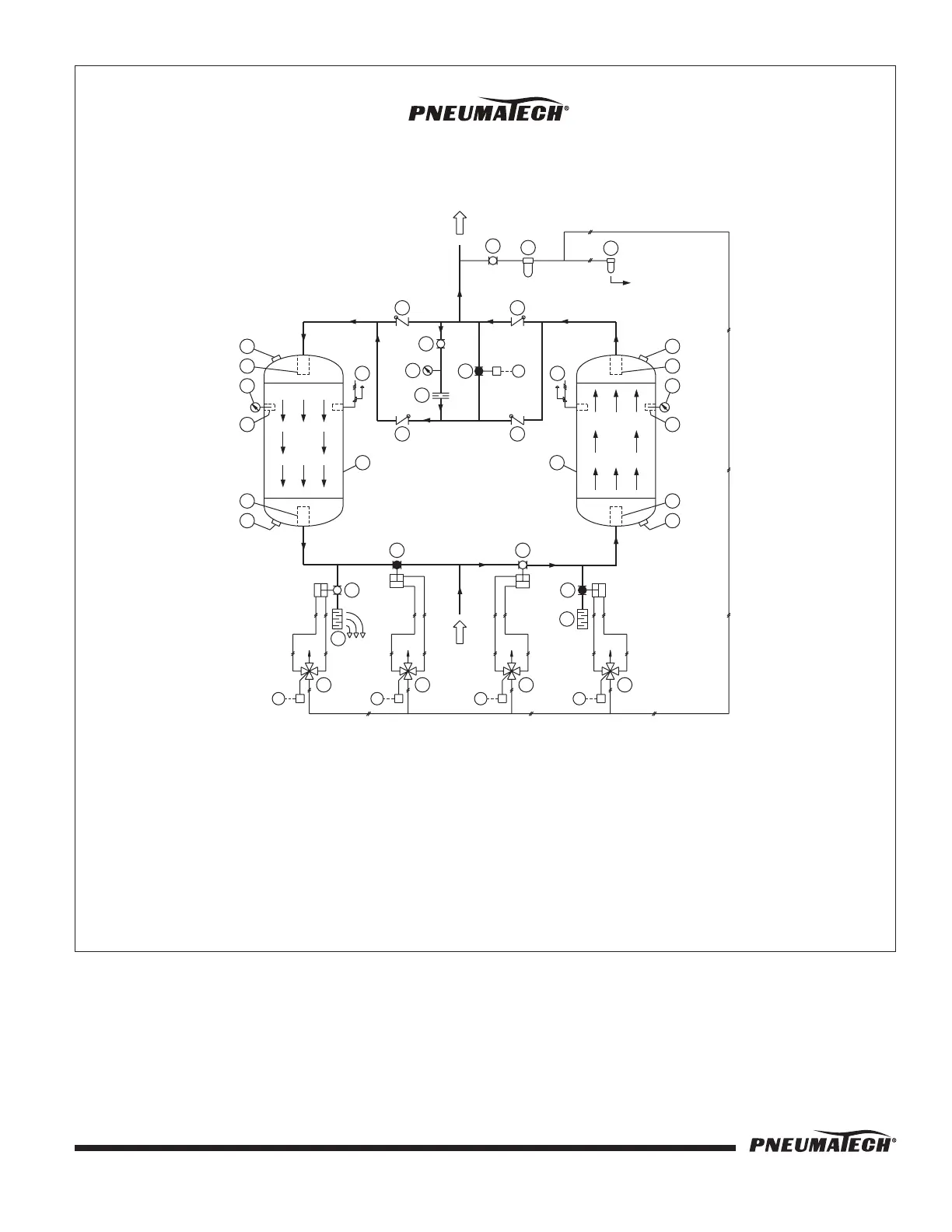

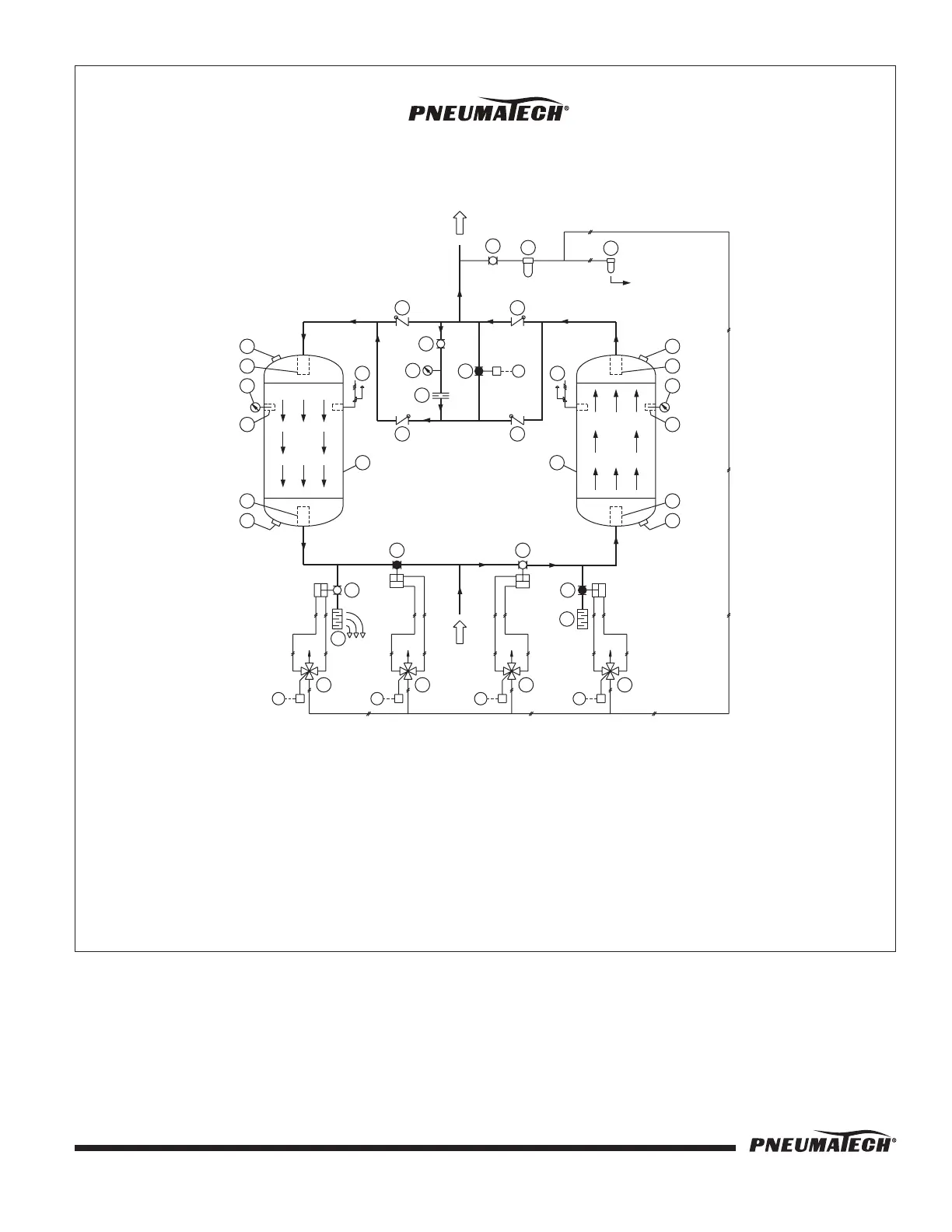

FIGURE 3 — PH & EH SERIES FLOW DIAGRAM

FLOW

DRYING

S

EX

21

9

8

OPEN

S

SS

EX

19

INLET

AIR

5

2

CLOSED

EX

20

6

2

OPEN

5

CLOSED

9

FLOW

REGEN

7

11

9

1

4

OPEN

12

13

10

CLOSED

3

14

15

4

CLOSED

1

ES

ESESESES

CLOSED

S

3

OPEN

10

AIR OUTLET

16

17

18

22

8

9

9

9

11

7

PILOT AIR LINE

EX (SLIGHT BLEED)

6

TYPICAL PH SERIES

FLOW DIAGRAM

1. PRESSURE VESSEL

2. AIR INLET VALVE

3. AIR OUTLET CHECK VALVE

4. PURGE FLOW CHECK VALVE

5. PURGE VALVE

6. MUFFLER

7. DESICCANT FILL PORT

8. DESICCANT DRAIN PORT

9. DESICCANT SCREEN

10. PRESSURE RELIEF VALVE

11. PRESSURE GAUGE

12. PURGE ORIFICE ASSEMBLY

13. PURGE ADJUSTMENT PRESSURE GAUGE

14. PURGE ADJUSTING VALVE

15. REPRESSURIZING VALVE W/SOLENOID

16. PILOT AIR SHUT-OFF VALVE

17. PILOT AIR FILTER

18. MOISTURE INDICATOR (OPTIONAL)

19. 4 WAY LEFT TOWER SWITCHING SOLENOID

20. 4 WAY RIGHT TOWER SWITCHING SOLENOID

21. 4 WAY LEFT TOWER PURGE SOLENOID

22. 4 WAY RIGHT TOWER PURGE SOLENOID

NOTES: 1. THIS PROCESS & INSTRUMENT DRAWING IS NOT AN ISOMETRIC DRAWING,

THE RELATIVE POSITION OF VARIOUS EQUIPMENT IS PURELY SCHEMATIC.

2. VALVE POSITION SHOWN IN THIS DRAWING IS WITH THE RIGHT TOWER

DRYING & THE LEFT TOWER REGENERATING.

3. REPRESSURIZING VALVE LOCATED ON PH-400 AND LARGER AIR DRYERS.

EX - EXHAUST

ES - ELECTRICAL SIGNAL

Loading...

Loading...