ENGINE

2.12

and rings. See Honing to Oversize in this

chapter. Inspect cylinder for out of round.

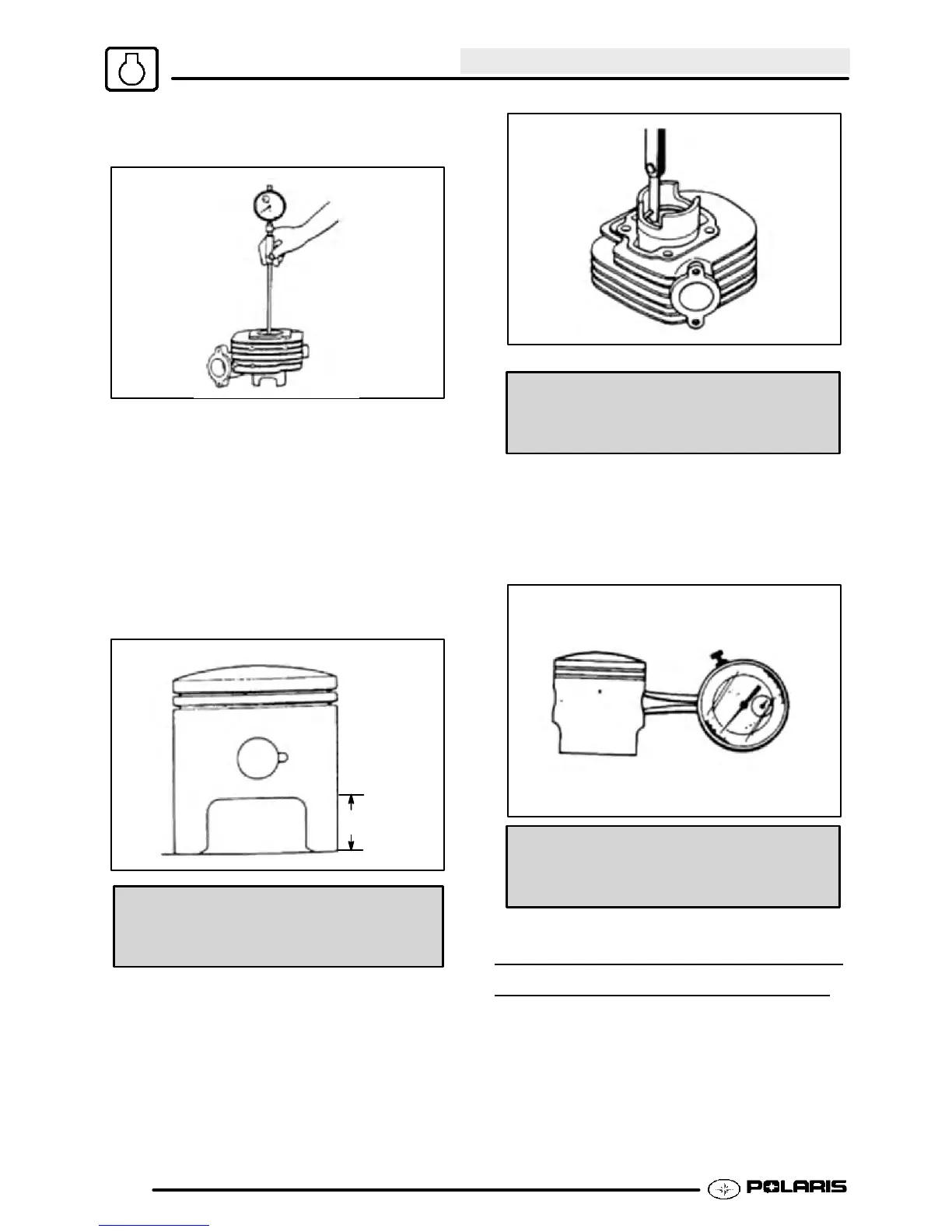

Piston Inspection

1. Inspect the piston for scoring or cracks in piston

crown or pin area. Excessive carbon buildup below

the ring land is an indication of piston, ring, or

cylinder wear. If damage is excessive, replace

piston. Piston-to-cylinder clearance should not

exceed .0047² (0.12 mm). Measure the piston 5/8²

(15 mm) from bottom. Then measure inside

diameter of cylinder. The difference between these

measurements should not exceed .0047² (0.12

mm).

5/8² (15 mm)

Piston to Cylinder Clearance:

50 cc: .00138--.00177” (.035--.045 mm).

90 cc: .00118--.00197” (0.03 -- .05 mm)

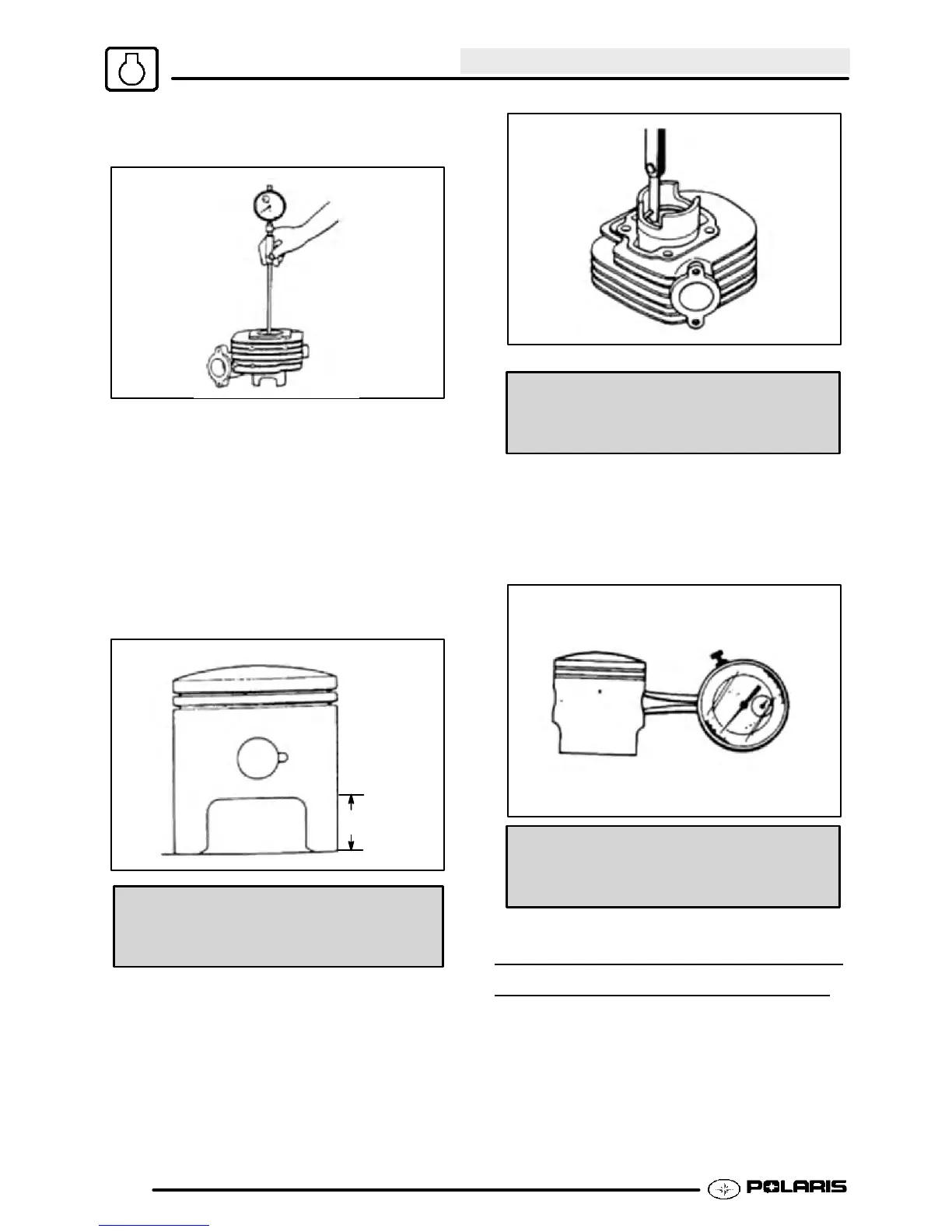

Piston Ring Installed Gap

2. Position piston ring 1/2² (1.3cm) fromthetop of the

cylinder using the piston to push it squarely into

place. Measure installed gap with a feeler gauge

at both the top and bottom of the cylinder.

Replace rings if the installed end gap exceeds the

service limit.

Piston Ring Installed Gap

Service Limit:

.030I (0.75 mm)

Piston Pin Hole Inspection

1. Using a telescoping gauge or similar bore gauge,

measure the inside diameter of the piston pin hole

on both sides of the piston. Replace if diameter

exceeds .395² (10.03 mm)

Piston Pin Hole

Service Limit:

.395I (10.03 mm)

HONING ---- CYLINDER HONE

SELECTION &

PROCEDURE

Polaris recommends using only a rigid hone or arbor

honing machine which has the capability of

oversizing. Selecting a hone which will straighten as

well as remove material from the cylinder is very

important. Using a common spring loaded glaze

breaker for honing is never advised.

Enfocus Software - Customer Support

Loading...

Loading...