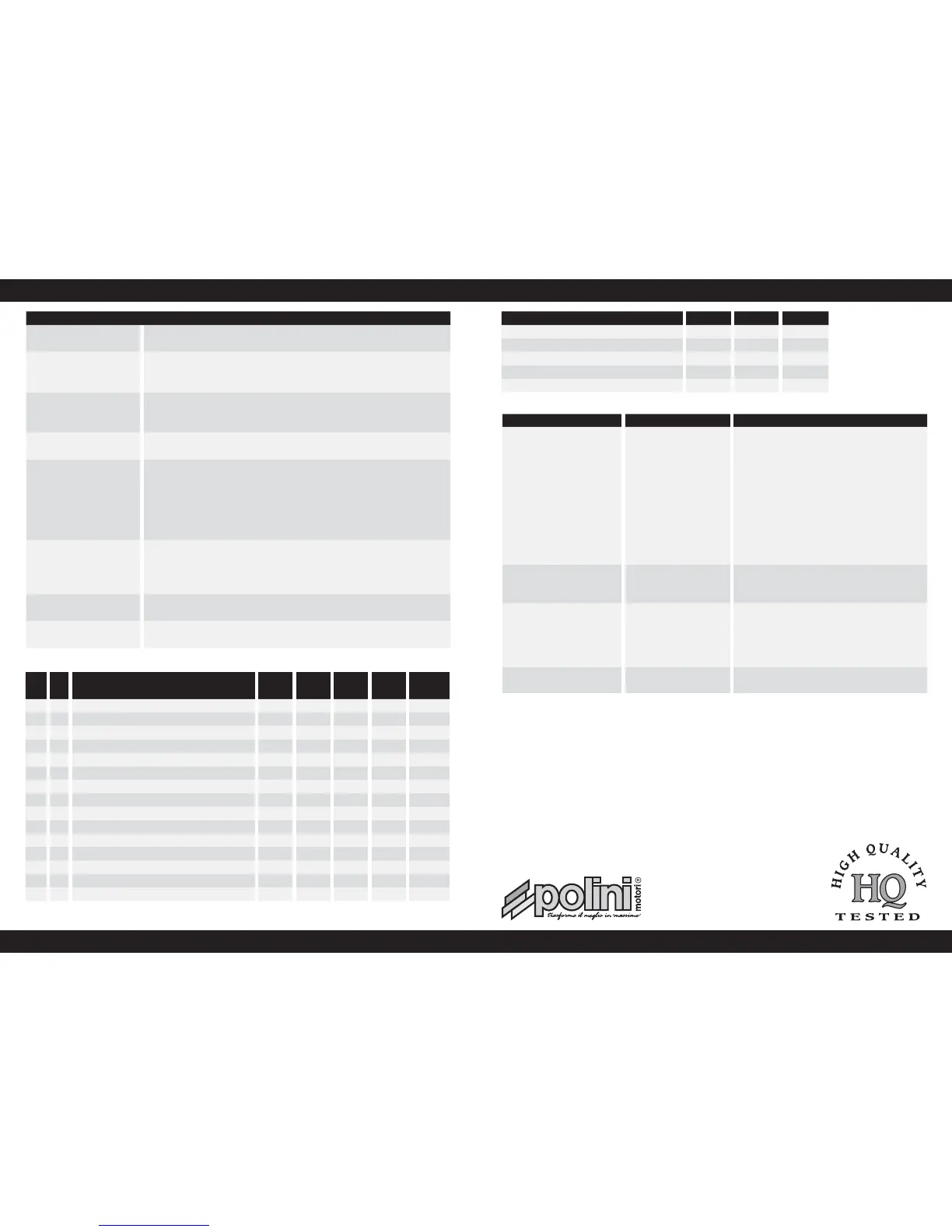

12- SERVICING TABLE

At every use Check the bolts and screws tightening

Check the silent-block conditions

After the first 10 hours Change the gear oil level

Check carburation

Check the spark plug electrode distance

Every 25 hours Replace the spark plug

Clean the air filter

Replace the muffler springs

Every 50 hours Change the gear oil

Replace the silencer deadening material

Every 100 hours or every year Replace the air filter

Replace the starter rope

Replace the diaphragm and clean it

Replace the silent-block

Replace the fuel system pipes

Replace the reed valves

Every 100 hours Check the piston and piston rings

Replace the pin and rollers cage

Decarbonise and clean the decompression hole

Disassemble the reduction gear and check the clutch and bell wear

Every 200 hours Replace the piston and piston rings

Replace the reed valve

Every 400 hours Replace all the bearings and seals

Replace the crankshaft

100 200

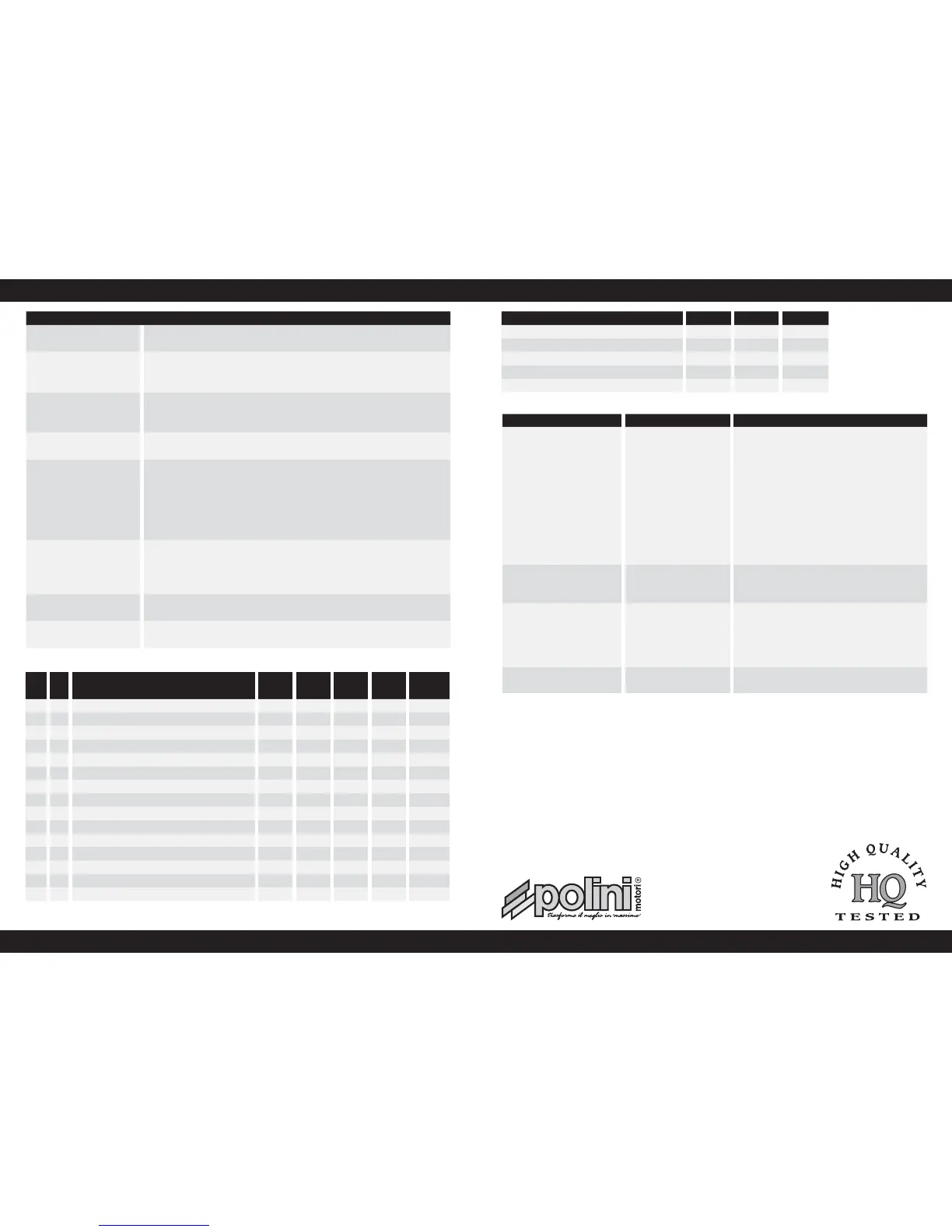

TIGHTENING TORQUE VALUE FOR ENGINE BOLTS AND

SCREWS

M N.m Kgf.m Lbf.ft

Locking

compound

•

HEAD NUTS THOR 100 7 14 1,4 10,3

•

HEAD NUTS THOR 200 6 14 1,4 10,3

•

HEAD NUTS THOR 200 8 22 2,2 16,2

•

CRANKSHAFT NUT - CLUTCH SIDE 12 60 6 44,4

• •

CRANKSHAFT NUT - IGNITION SIDE 10 40 4 29,5

• •

PROPELLER CENTRAL SCREW 10 40 4 29,5 LOCTITE 243

• •

SPARK PLUG 20 2 14,8

•

COUNTERSHFAT THOR 200 12 60 6 44

•

CLUTCH NUT THOR 200 20 80 8 59

• •

CRANKCASE SCREWS 6 8 0,8 5,9

• •

CARBURATOR LOCKING SCREWS 6 8 0,8 5,9

• •

INTAKE MANIFOLD LOCKING SCREWS 6 8 0,8 5,9

• •

MUFFLER STUDS NUTS 6 10 1 7,4 LOCTITE 270

• •

SILENCER LOCKING SCREWS 8 15 1,5 11,1 LOCTITE 243

• •

MUFFLER LOCKING SCREWS 8 15 1,5 11,1 LOCTITE 243

STANDARD TIGHTENING TORQUE VALUES N.m Kgf.m Lbf.ft

5mm Bolts and nuts 6 0,6 4,44

6mm Bolts and nuts 10 1 7,40

8mm Bolts and nuts 25 2,5 18,50

10mm Bolts and nuts 45 4,5 33,30

12mm Bolts and nuts 55 5,5 40,70

13- PROBLEMS DIAGNOSTIC REASON REMEDY

The engine doesn't start Out of petrol Add petrol

Petrol doesn't reach the carburetor Check the fuel system circuit

Old or wrong petrol Empty the tank and the fuel system circuit and replace the petrol.

Flooded engine

Remove the spark plug, start the engine, dry or replace the

spark plug.

Defective spark plug Replace it

Blackened spark plug or wet Clean and dry the spark plug or replace it

Earthened switching off cable Check the wiring

Spark plug hood Check it

Carburetor has problems Clean and check it; eventually replace the diaphragm

No spark Check the ignition, coil and wiring

The engine doesn't idle Dirty carburetor Calibrate the carburetor

Out-of-adjustment screws Clean and check it; eventually replace the diaphragm

Defective spark plug Replace it

The engine doesn't reach the maxi-

mum rpm

Wrong carburetion Calibrate the carburetor

The carburetor has problems Clean and check it; eventually replace the diaphragm

The reed valve has problems Replace the reeds or the whole reed valve

Dirty air filter Clean or replace it

Dirty exhaust system Clean or replace the deadening material

Engine revved up when idling Out-of-adjustment screws Calibrate the carburetor

Air through the gaskets Replace the gaskets and seals

Loading...

Loading...