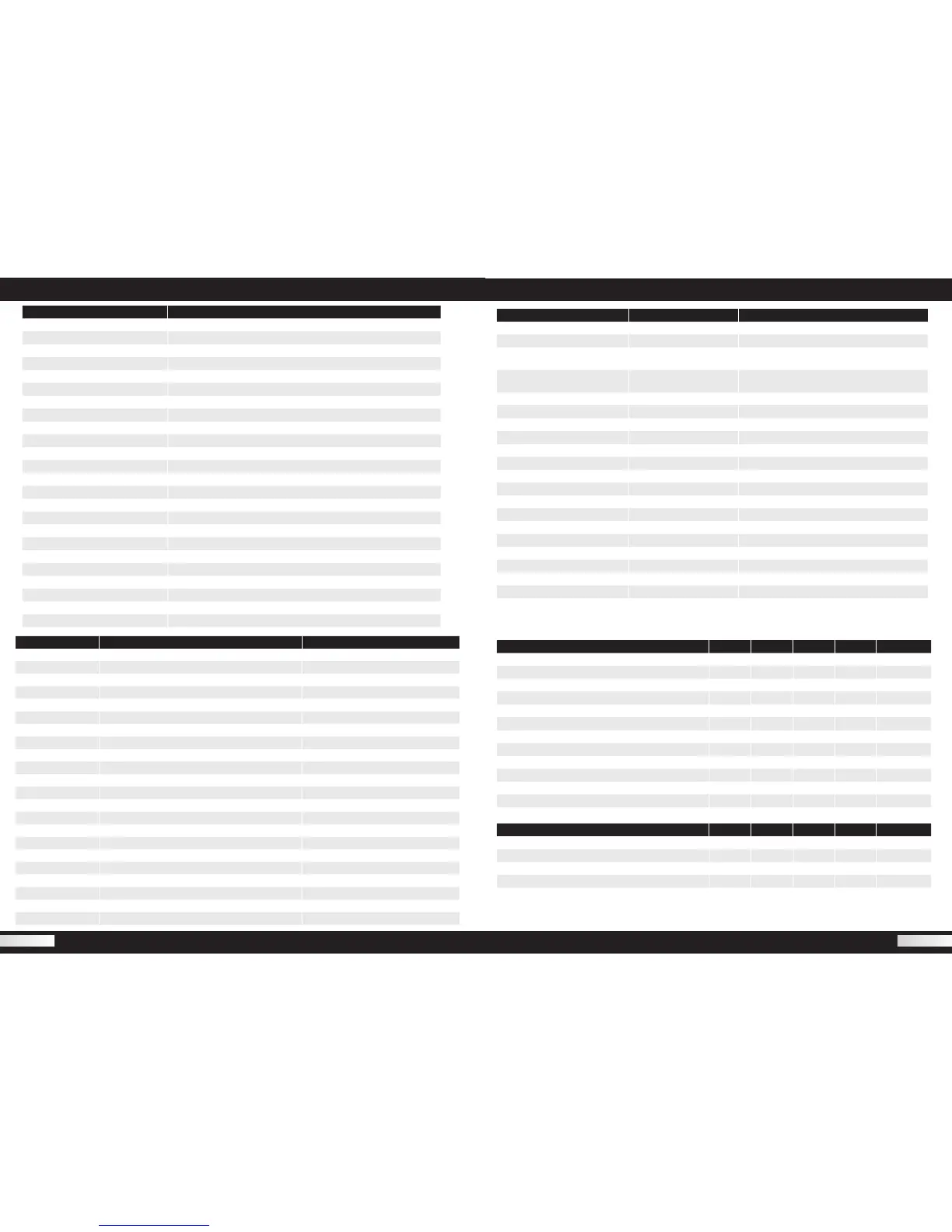

12- SERVICING TABLE

Every use Check the bolts and screws tightening

Check the silent-block conditions

After the first 10 hours Replace the gear oil

Check the carburation

Every 50 hours Replace spark plug NGK BR 10 ES

Clean the air filter

Replace the gear oil

Check the starter wearing and eventually replace the rope and the lockpins

Every 100 hours or every year Replace the air filter

Replace the starter rope and the lockpins

Replace the diaphragm and clean it

Replace the silent-block

Replace the fuel system pipes

replace muffler springs

Check the reed valve

Every 100 hours Check the piston, the piston rings and the small end bearing

Decarbonize and clean the decompression hole

Every 150 hours Remove the gear and check the clutch and bell wear

Replace the piston, the piston rings and the small end bearing

replace the silencer deadening material

Replace the reed valve

Every 300 hours Replace all the bearings and seals

Replace the crankshaft

Replace the cylinder

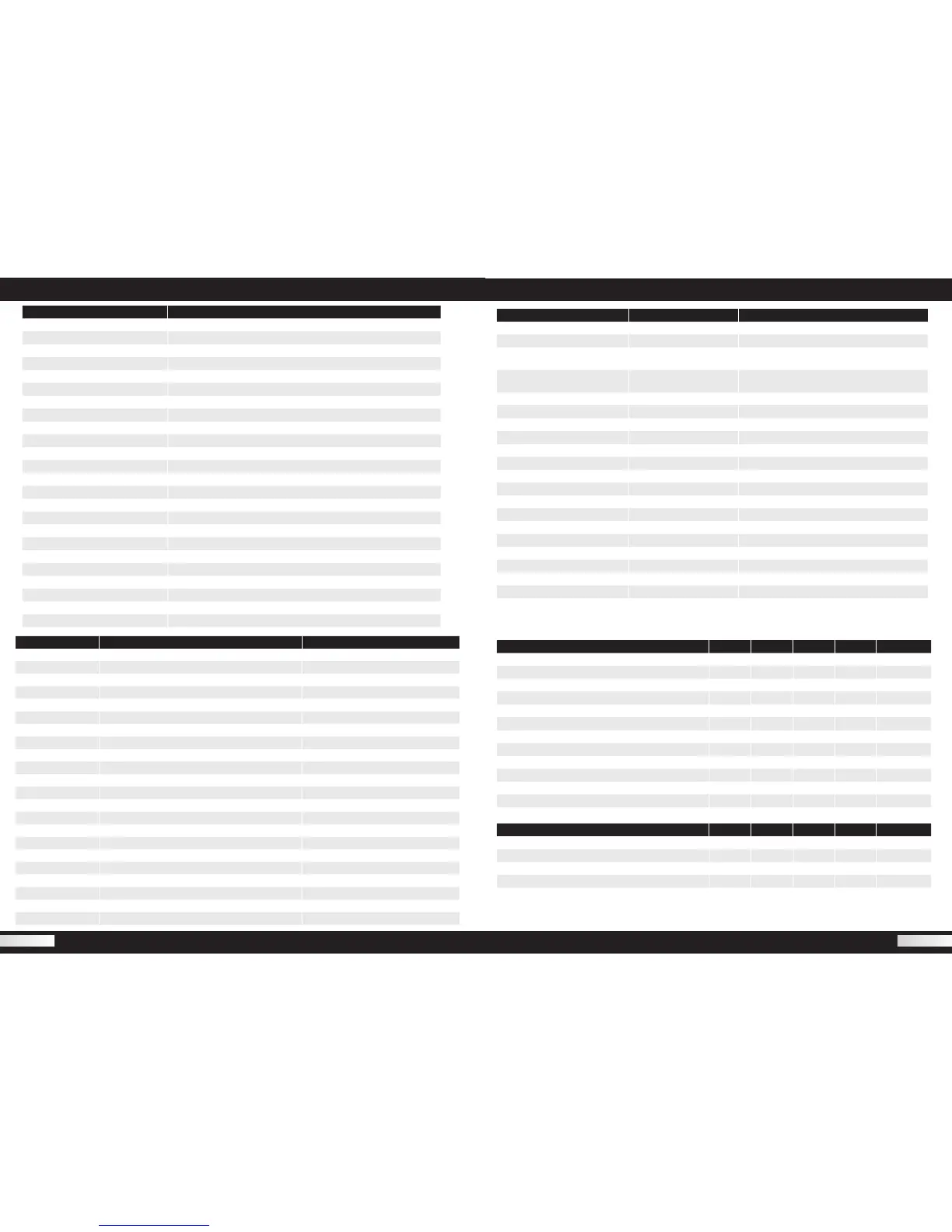

TECHNICAL SCHEDULE THOR 250 THOR 250 DUAL SPARK

Polini engine 2-stroke monocylinder 2-stroke monocylinder

Cooling Liquid cooled Liquid cooled

Bore for stroke 72 x 60 72 x 60

Displacement 244 cm3 244 cm3

Power 36 HP at 7500 R.P.M. 36,5 HP at 7500 R.P.M.

Cylinder aluminum with Gilnisil coating aluminum with Gilnisil coating

Compression ratio 11,5:1 11,5:1

Piston Two chromium plated rings (mm 1) - Two chromium plated rings (mm 1) -

Intake Reed valve in the crankcase Reed valve in the crankcase

Carburetor Ø 28 bowl carb. Ø 28 bowl carb.

Air filter Air box Air box

Ignition 1 Electronic with possible battery charge Electronic

Ignition 2 - Battery fed

Battery charger arrangement

output power: 80W at 5500 rpm output power: 80W at 5500 rpm

Spark plug hood 5k resistance 5k resistance

Fuel type Lead free petrol with 2% synthetic oil Lead free petrol with 2% synthetic oil

Gear reduction unit Helical teeth in oil bath with 2,8 reduction ratio Helical teeth in oil bath with 2,8 reduction ratio

Starter

Pull starter with self-winding rope-FLASH STARTER (electric starter as OPTIONAL) Electric+Pull starter with self-winding rope -FLASH STARTER

Clutch Centrifugal in oil bath Centrifugal in oil bath

Muffler Expansion with aluminum silencer Expansion with aluminum silencer

Engine weight 18 Kg (19 Kg with elect. starter) without radiator 18,5 Kg (19,5 Kg + electric starter) without radiator

Propeller rotation Clockwise Clockwise

TIGHTENING TORQUE VALUE for ENGINE BOLTS AND SCREWS

M N.m Kgf.m Lbf.ft

Locking compound

HEAD SCREWS 6 12 1,2 8,8

HEAD NUTS 8 18 1,8 13,2

CLUTCH NUT 20 100 10 74

CRANKSHAFT NUT (IGNITION SIDE) 12 80 8 39

PROPELLER CENTRAL NUT (LEFT THREAD) 10 80 8 39

SPARK PLUG 20 2 14,8

CRANKCASE SCREW 6 8 0,8 5,9

COUNTERSHAFT NUT 12 60 6 44,2

INTAKE MANIFOLD LOCKING SCREWS 6 8 0,8 5,9

MUFFLER STUDS NUTS 8 18 1,8 13,2 LOCTITE 270

SILENCER LOCKING SCREWS 8 15 1,5 11,1 LOCTITE 243

MUFFLER LOCKING SCREWS 8 15 1,5 11,1 LOCTITE 243

STANDARD TIGHTENING TORQUE VALUE N.m Kgf.m Lbf.ft

5MM BOLT AND NUT 6 0,6 4,44

6MM BOLT AND NUT 10 1 7,40

8MM BOLT AND NUT 25 2,5 18,50

10MM BOLT AND NUT 45 4,5 33,30

12MM BOLT AND NUT 55 5,5 40,70

13. ENGINE PROBLEM DIAGNOSTIC CAUSE SOLUTION

The engine doesn't start Out of petrol Add petrol

Petrol doesn't reach the carburetor Check the fuel system circuit

Old or wrong petrol

Empty the tank and the fuel system circuit and replace the

petrol.

Flooded engine

Remove the spark plug, start the engine, dry or replace the

spark plug.

Defective spark plug Replace it

Blackened or wet spark plug Clean and dry the spark plug or replace it

Earth switching off cable Check the tightening

Spark plug hood wrong installed Check it

Carburetor has problems

Clean and check it; eventually replace the diaphragm

No spark Check the ignition, coil and wiring

The engine doesn't idle Dirty carburetor Clean and check the carburetor

Out-of-adjustment screws Calibrate the carburetor again

Defective spark plug Replace it

The engine doesn't reach the maximum rpm

Wrong carburetion Calibrate the carburetor

The carburetor has problems

Clean and check it; eventually replace the diaphragm

The reed valve has problems Replace the reeds or the whole reed valve

Dirty air filter Clean or replace it

Dirty exhaust Clean or replace the deadening material

Engine revs up when idling Out-of-adjustment screws Calibrate the carburetor

Air through the gaskets

Replace the gaskets and seals

Loading...

Loading...