13

Engine,

Crankshaft,

Pistons

REGRINDING

CRANKSHAFT

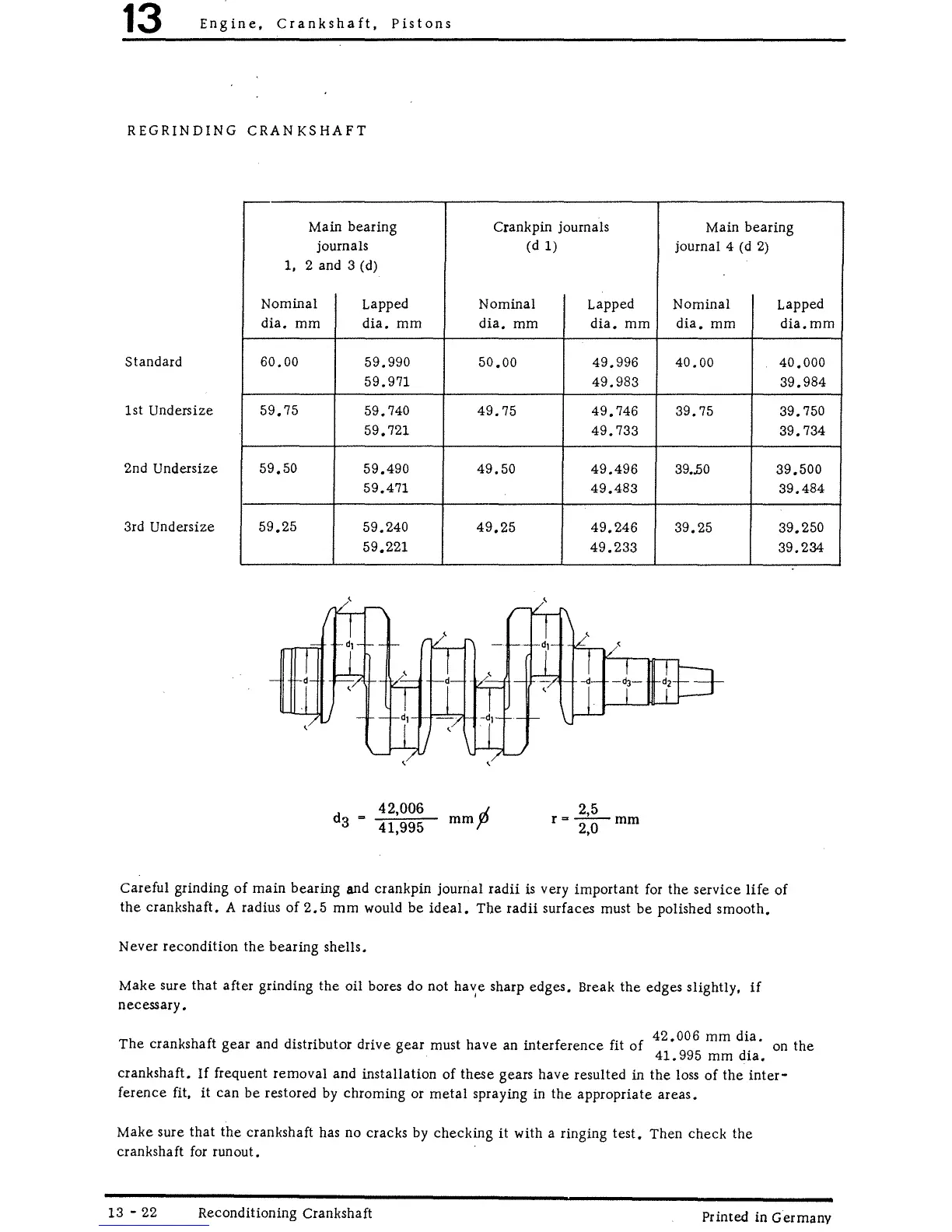

Main bearing

Crankpin journals Main bearing

Standard

1st Undersize

2nd Undersize

3rd Undersize

journals

(d

1)

1,

2and3(d)

Nominal

Lapped Nominal

dia.

mm

dia.

mm

dia.

mm

60.00

59.990

50.00

59.971

59.75

59.740

49.75

59.721

59.50

59.490

49.50

59.471

59.25

59.240

49.25

59.221

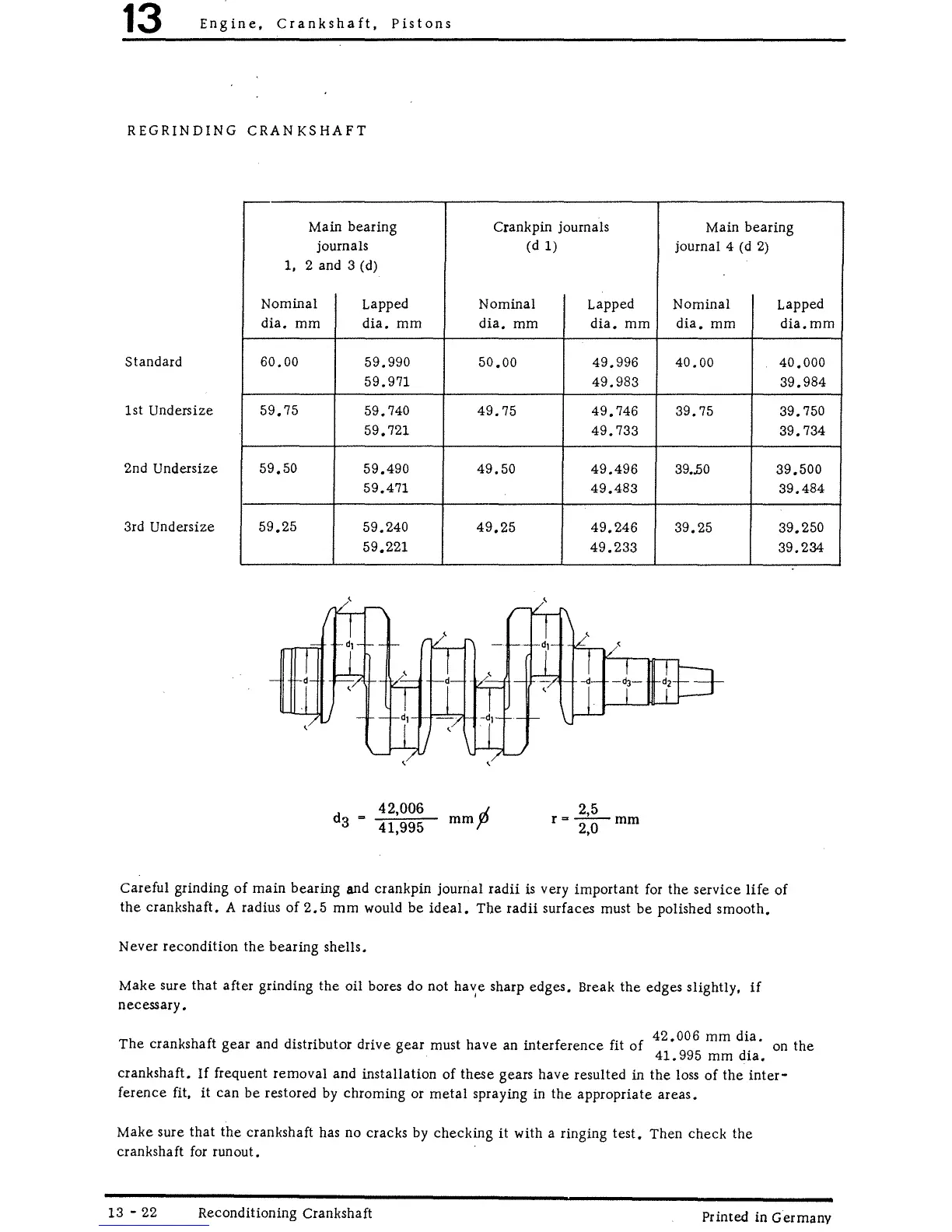

d

3

_ 42,006

mm

d.

41,995 ?

Lapped

dia.

mm

49.996

49.983

49.746

49.733

49.496

49.483

49.246

49.233

2,5

r=--mm

2,0

journal 4 ( d

2)

Nominal

Lapped

dia.

mm

dia.mm

40.00

40.000

39.984

39.75

39.750

39.734

39

•

.50

39.500

39.484

39.25

39.250

39.234

Careful grinding

of

main

bearing and crankpin journal

radii

is

very important

for

the service

life

of

the

crankshaft. A radius

of

2.5

mm

would be

ideal.

The

radii

surfaces must be polished smooth.

Never recondition the bearing shells.

Make sure

that

after grinding the oil bores do not

ha~e

sharp edges. Break the edges slightly,

if

necessary.

f

· . f

f.

42.006

mm

dia.

h

The

cranksha t gear and d1stnbutor drive

gear

must have an inter

erence

1t

of

995

d. on t e

41.

mm 1a.

crankshaft.

If

frequent removal and installation of these gears have resulted in the loss

of

the

inter-

ference fit,

it

can be restored

by

chroming or

metal

spraying in the appropriate

areas.

Make sure

that

the

crankshaft has no cracks

by

checking

it

with a ringing

test.

Then check the

crankshaft

for

runout.

13 - 22

Reconditioning Crankshaft

Printed in Germany

Loading...

Loading...