Industrial Damper

Installation, Operation, and Maintenance Manual

D

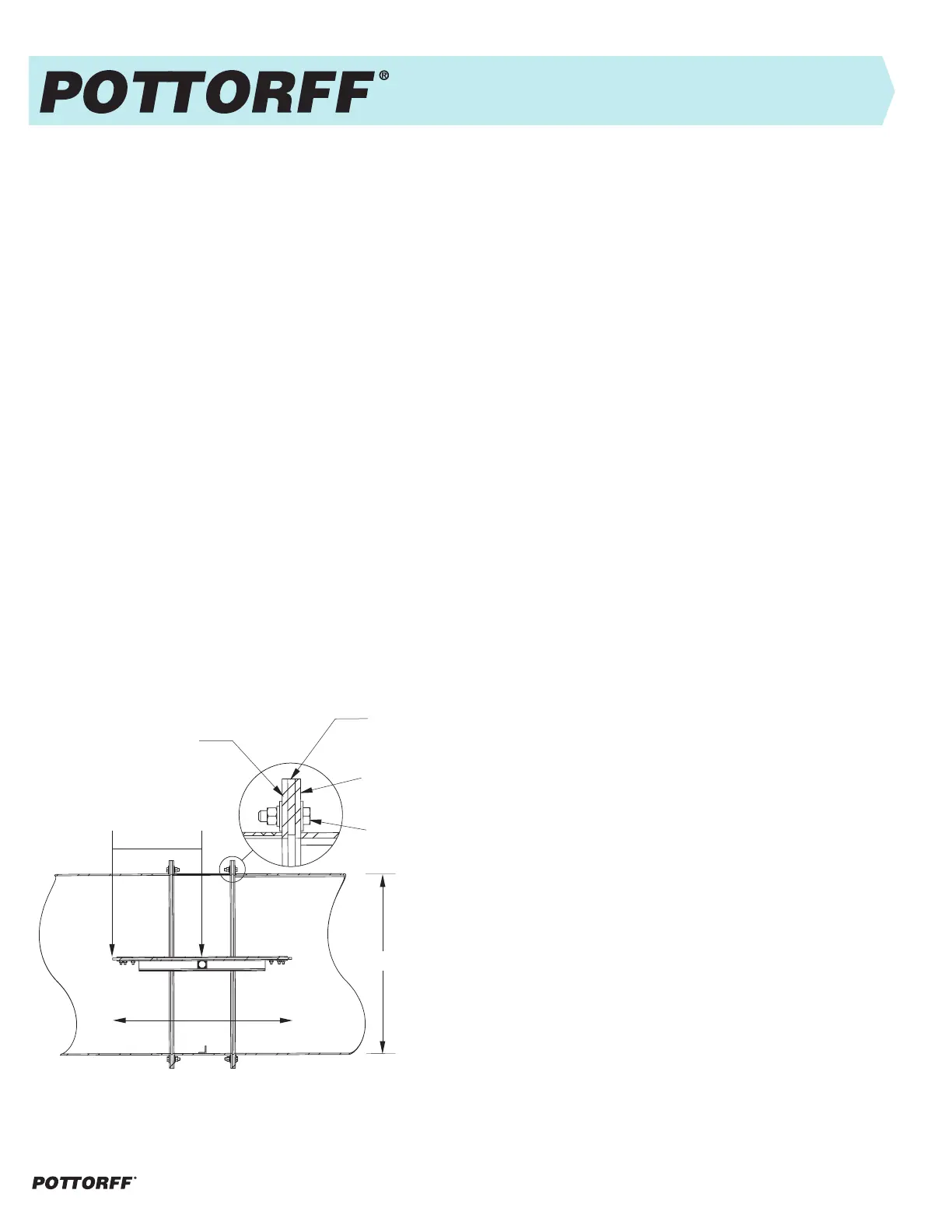

Duct by others

Damper

Flange

Air Flow is

Bi-Directional

D/2 + 0.25"

Gasket or Sealant

(By others)

Connecting Hardware

(By others)

Duct Mount Installation

Industrial Round Damper Installation

Figure 2

Industrial Damper IOM 2 of 4, February, 2024 pottorff.com

Do's

1. DO use provided lifting lugs.

2. DO install bolts into all supplied mounting holes, then tighten in an

even and staggered pattern to evenly compress the flange gasket (if

using).

3. DO check that the mating flange is flat, square, and parallel to the

damper flange.

4. DO check that damper blade(s) and linkages do not interfere with the

mating opening or duct when the damper is cycled between open

and closed positions.

Don'ts

1. DO NOT lift damper by blade(s).

2. DO NOT use actuator, linkage, or axles as lifting point.

3. DO NOT pry flanges to mate flange holes with opening or duct

flange as the frame could become warped, twisted, bent, or pulled

out-of-round causing binding.

4. DO NOT tighten mounting bolts by working around damper.

Please follow these instructions carefully. Failure to do so may void the

warranty. If the unit is supplied with an actuator, refer to the actuator

installation manual for details on the actuator before installation as well.

If the actuators were factory installed some adjustment may be required

after installation.

Start Up

Precautions should be taken before startup of the damper. All additional

safety accessories should be installed before starting the damper to

ensure the safety of everyone around. Rotate the blade(s) by hand to

ensure free movement of all components. Remove any construction

debris, loose hardware, tools, etc., from inside the damper and opening

or duct.

If electrical power is required, check all electrical connections before

turning on power. The supplied voltage must match the voltage required.

A qualified electrician must be used. Improper connections are hazardous

and can cause permanent damage to the electrical equipment.

If any NEMA electrical enclosure is supplied, use appropriate electrical

connections to maintain the NEMA rating. All wiring and fusing must

be in accordance with national electric code, local code, and project

specification requirements. If the unit is supplied with an actuator, refer to

the actuator installation manual for details on the actuator before startup

as well.

If pneumatic power is required, check all pneumatic connections. The

supplied pressures must match the pressures required. A qualified

technician must be used. Improper connections are hazardous and can

cause permanent damage to the pneumatic equipment. All plumbing

must be in accordance with national code, local code, and project

specification requirements. If the unit is supplied with an actuator, refer to

the actuator installation manual for details on the actuator before startup

as well.

Single Section Dampers

If the damper is supplied without mounting holes, drill or punch as

required. Pottorff is not responsible for corrosion around field punched or

drilled holes on painted dampers. Unless specifically designed for vertical

blades, the damper must be mounted with blade axis horizontal. Connect

the damper to the mounting location using the proper hardware. Attach

the damper to all connection points before tightening bolts. Confirm that

the damper is square, straight, and level, and free from bending, twisting,

or racking. Manually operate the damper to ensure that it operates freely.

Round Dampers

For round dampers, use appropriate gasketing (supplied by others)

between mating flanges. If the damper is supplied without mounting

holes, drill or punch as required. Pottorff is not responsible for corrosion

around field punch/drilled holes on painted dampers. Closed cell sponge

rubber, solid rubber, maximum 60 durometer is recommended.

Allow minimum of half of the blade diameter upstream or downstream,

plus 0.25" (6) for the blade seal material in the duct for blade rotation. The

damper can be mounted vertically or horizontally as a long axle is parallel

to the ground. Isolate damper from high vibratory loading. (See Figure 2)

Multi-Section Dampers

Follow instructions for single section dampers. Additionally, position

damper sections together in opening or duct. Align and match frame

markings or labels on adjacent sections. Fasten adjacent sections

together on front and back sides with screws or nuts and bolts. Shim

damper frame and opening or duct as required to prevent distortion of

frame. Multi-section dampers require bracing to support the weight of

the assembly and to hold against system pressure. Bracing should

support the damper horizontally, minimum 8 feet center-to-center. Large

vertical assemblies and high system pressure may require additional

bracing. All additional bracing and supports designed, supplied, and

installed by others.

Loading...

Loading...