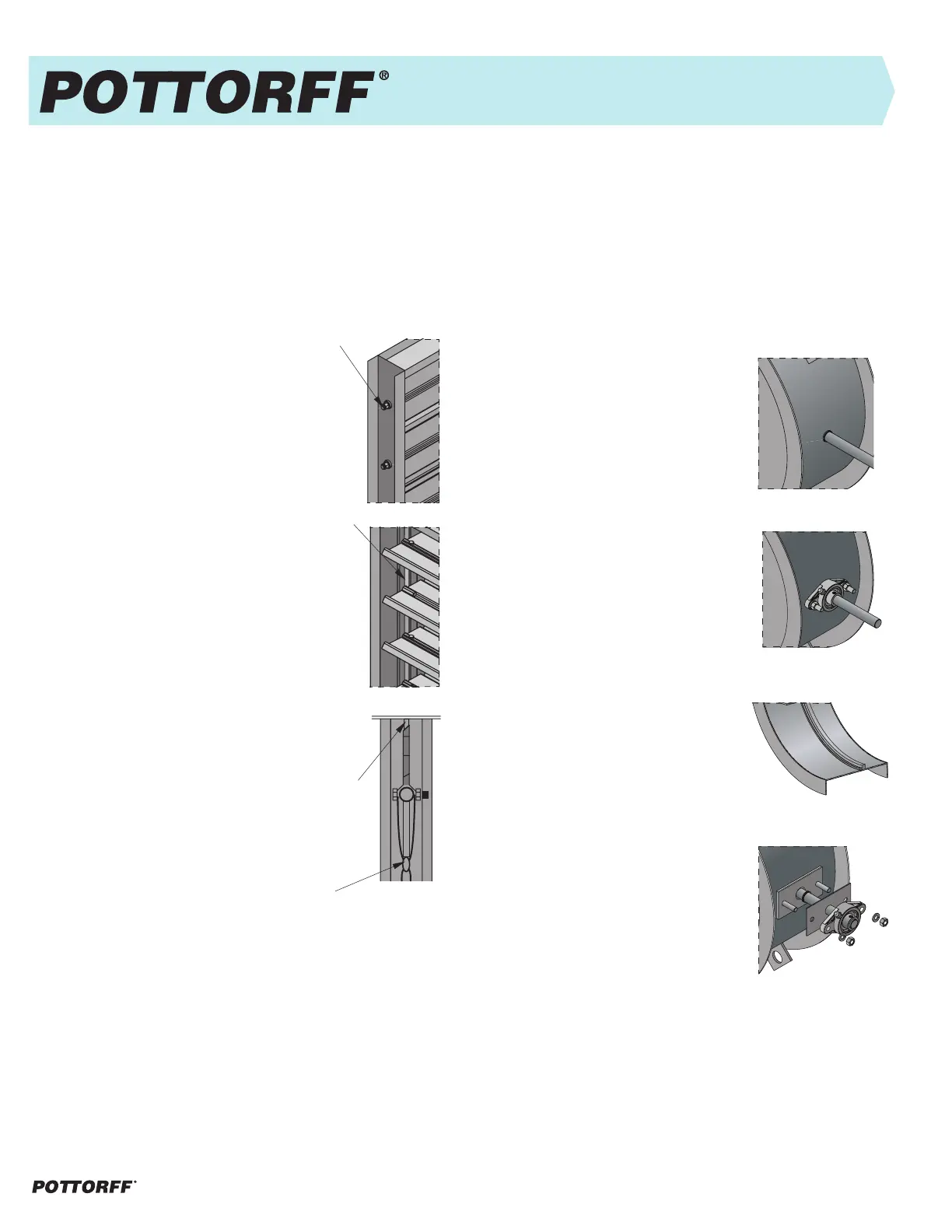

Bearings

Sleeve Bearing

Ball Bearing

Jamb Seal

Stop Seal

O-ring Axle Seal

Blade Seal

Blade Seal

Rectangular Dampers

1. Clean the dampers. Over time, dirt and

grime may collect on damper surfaces.

This can be a hindrance to airflow as

well as reduce the sealing efficiency of

the damper when closed. Be especially

careful in cleaning non-metallic blade

seals as they can be torn if abused. Mild

soap and water is the recommended

cleaning agent. Avoid abrasives and

solvents as these could degrade seals,

adhesives, oil on bearings, etc.

2. Check moving parts such as crank arms,

linkages, pins, blades, etc., to make sure

they move freely. While not required,

lubricating these components can prevent

possible rusting and unnecessary friction

increase. Use only a molybdenum spray

oil or similar graphite-based oil as regular

lubricating oil will attract dirt.

3. The bearings located on the blade axles

do not require lubrication.

4. If installed, inspect the blade seals and

stop seals for damage such as tears and

nicks. If damaged, replace as needed.

5. Check for worn shaft seals if applicable

and repair or replace as necessary.

6. Look for debris that may be interfering

with blade closure or effective sealing of

the blades and remove.

7. Check for loose hardware.

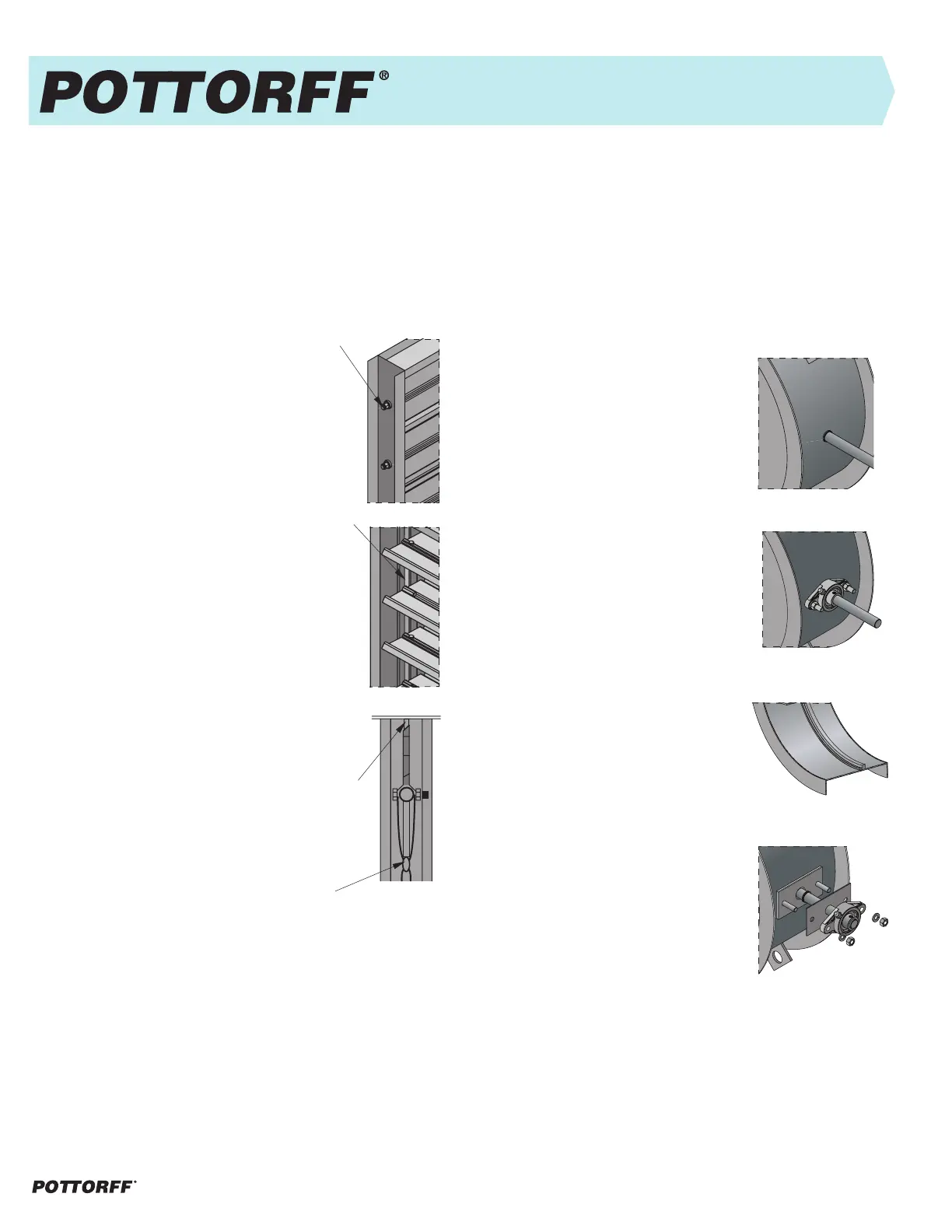

Round Dampers

1. Clean the dampers. Over time, dirt and

grime may collect on damper surfaces.

This can be a hindrance to airflow as

well as reduce the sealing efficiency of

the damper when closed. Be especially

careful in cleaning non-metallic blade

seals as they can be torn if abused. Mild

soap and water is the recommended

cleaning agent. Avoid abrasives and

solvents as these could degrade seals,

adhesives, oil on bearings, etc.

2. Check moving parts such as crank arms,

linkages, pins, blades, etc., to make sure

they move freely. While not required,

lubricating these components can prevent

possible rusting and unnecessary friction

increase. Use only a molybdenum spray

oil or similar graphite-based oil as regular

lubricating oil will attract dirt.

3. If equipped, sleeve bearings located on

the blade axle do not require lubrication.

Ball bearings with grease fittings should

be lubricated twice a year minimum with

a NLG1 Grade 2 lithium 12-hydrostearate

grease.

4. If installed, inspect the blade seals and/

or axle o-rings for damage such as

tears and nicks. If damaged, replace as

needed.

5. Check for worn shaft seals if applicable

and repair or replace as necessary.

6. Look for debris that may be interfering

with blade closure or effective sealing of

the blades and remove.

7. Check for loose hardware.

Refer to the actuator installation manual

for details on the actuator maintenance

requirements as well.

Refer to the actuator installation manual

for details on the actuator maintenance

requirements as well.

Maintenance

Pottorff dampers are designed to be maintenance free under normal

operation. Dampers are to be installed square, level, and straight to prevent

binding during operation. The following damper maintenance is suggested

to help ensure proper operation and increase life expectancy of the damper.

The frequency of maintenance should be determined by the severity of the

application. Before performing maintenance ensure that the damper has

been locked out. The blades should also be securely blocked to eliminate the

potential for movement while maintaining.

Industrial Damper

Installation, Operation, and Maintenance Manual

Industrial Damper IOM 3 of 4, February, 2024 pottorff.com

Loading...

Loading...