22

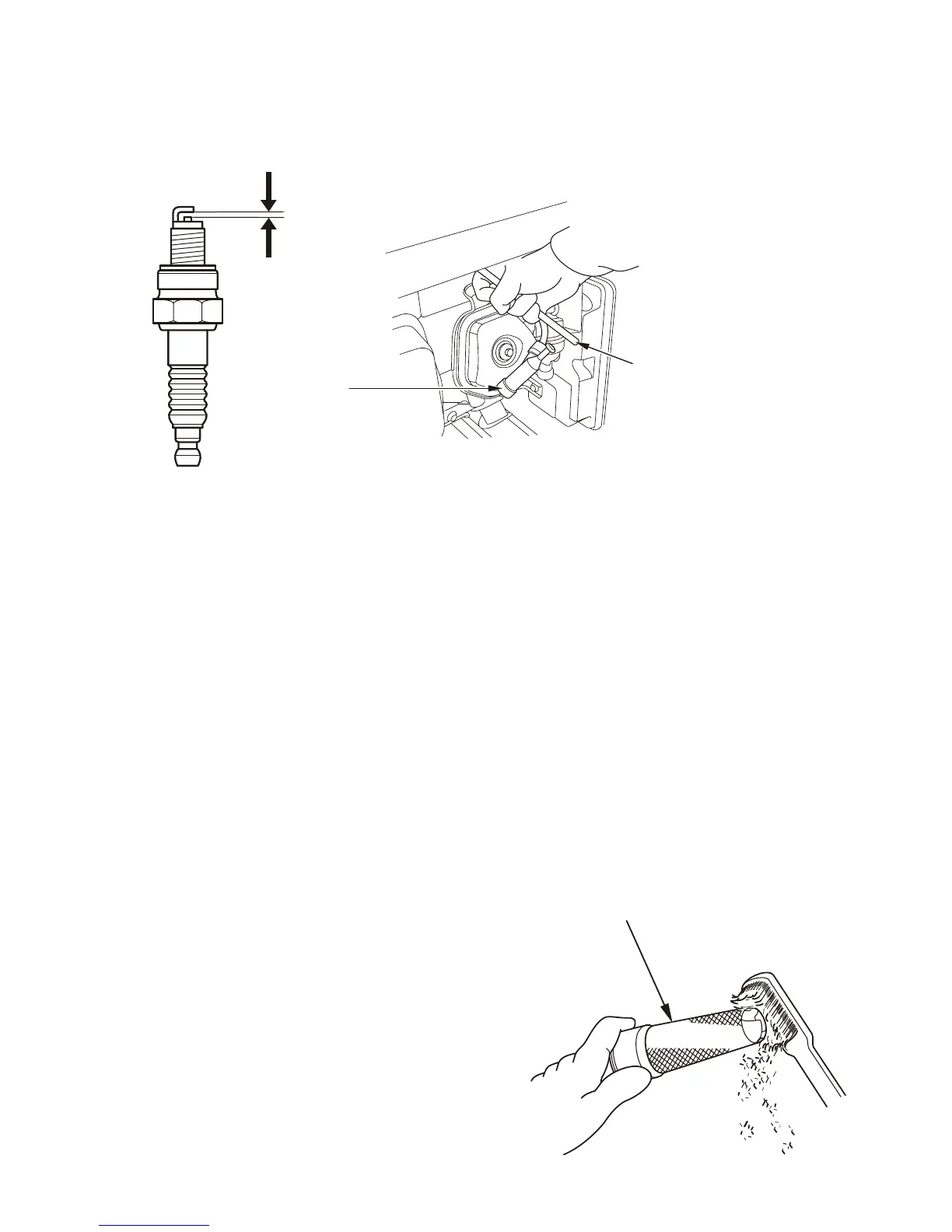

5. Measure the plug gap with a feeler gauge.

Correct as necessary by carefully bending the side electrode.

The gap should be: 0.028-0.031 in (0.70--0.80 mm)

PLUG CAP

SPARK PLUG WRENCH

0.028-0.031 in

(0.70-0.80mm )

7. Check that the spark plug washer is in good condition, and thread the sparkplug in by hand

to prevent cross-threading.

8. After the spark plug is seated, tighten with a spark plug wrench to compress the washer.

— If installing a new spark plug, tighten 1/2 turn after the spark plug seats to compress the

washer. If reinstalling a used spark plug, tighten 1/8-1/4 turn after the spark plug seats to

compress the washer.

NOTICE: The Spark plug must be securely tightened. An improperly tightened Spark plug

can become very hot and could damage the engine. Never use spark plugs which

have an improper heat range. Use only the recommended Spark plugs or

equivalent.

Spark Arrester Maintenance

If the generator has been running, the muffler will be very hot. Allow it to cool before

proceeding.

The spark arrester must be serviced every 100 hours to keep it functioning as designed.

Clean the spark arrester as follows:

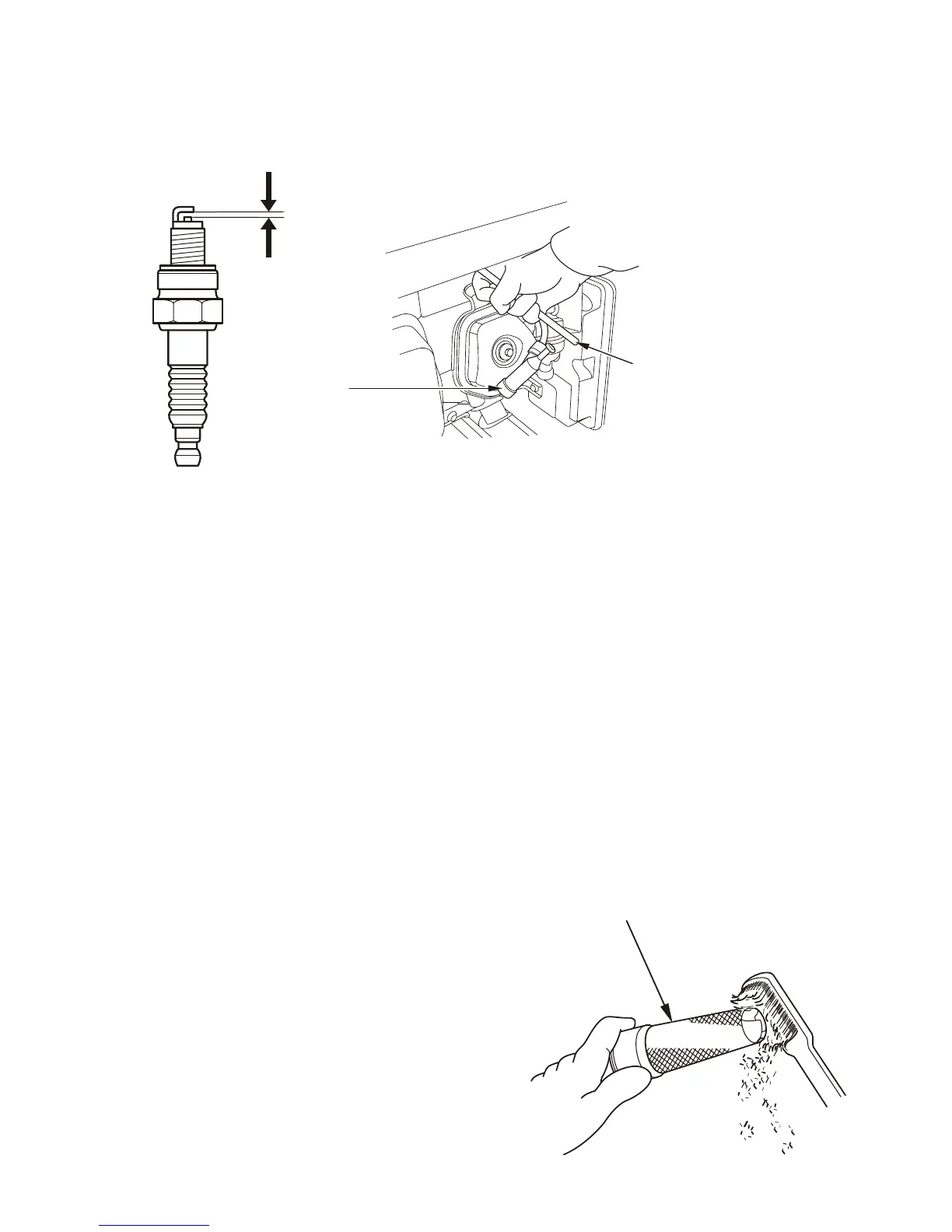

1. Loosen the screw by the exhaust port of the

muffler and remove the spark arrester.

2. Use a brush to remove carbon deposits from the

spark arrester screen.

Inspect the screen for breaks or tears and replace

it if necessary.

3. Install the spark arrester in the reverse order of

removal.

Loading...

Loading...